Clear back in July, after 21 years building, had my first flight. Wrote it up here:

http://user.xmission.com/~bifft/rv/first.htm

On this flight, I did a stall test, and after that the engine wouldn't develop full power. Flew right back and landed. Trying to troubleshoot the problem, found that there was some junk in the throttle body's last chance filter. Thought that this was the cause of the problem. Rotec recommends a 40micron fuel filter, all I had was Van's gascolator.

I suspect I put the dirt into the system when I drained the tanks to fix some leaks. I drained into my old 5 gallon tanks I have used for chainsaw gas, off road trips, etc. Dirt probably came out of there.

So, added a 10 micron fuel filter, cleaned out the lines, flew again. Had the exact same problem. Takeoff and climb out are fine. Slow down to do a stall test, engine won't go back to full power. Can only run below 2000 rpm or so. Fortunately this is plenty to fly back to the airport and land. Inspection found only a few specks in the throttle body filter, a bit more in the larger filter.

Monday went back and flushed out the fuel system. Got a filter funnel (https://www.amazon.com/gp/product/B000SOIRCG) and used the planes fuel pump to pump back into my tanks, using the filter funnel both going into the tanks and back into the plane. Did get some junk in the funnel, including a dead bug. Probably out of my tanks. However the first five gallons and the last five both took 9.5 minutes for a 31 gph flow rate. Should be plenty.

Doing ground running after flushing the tanks everything ran great. However in my many ground runs I had not been able to replicate the problem. After a long ground run trying to simulate a climb out I could get full power. I decided to fly, and closed the hangar, put on my parachute, etc. Engine then would not start. I suspect vapor lock because of the heat soak from the long run. Oil temp and CHT both read 180. It was getting late, so went home.

This morning got out to the airport to try again. There were some delays on the ground waiting for the tower to talk to me, so the taxi out to the runup area took longer than usual, by the video 10:33 after engine start. This time I was able to replicate the problem on runup. Unable to get full power, stopping right around 2000 rpm. Video link goes to just as I am powering up to full throttle.

https://youtu.be/u0DnhU08hEE?t=80

I taxied back and did some more tests near the hangar. After 30 seconds or so with the fuel pump on I could get full power (2200 rpm) after a brief stumble. With the electric pump off, I can't. See later runups in same video:

https://youtu.be/u0DnhU08hEE?t=231

What do people think? What should I try next? Obviously I don't want to fly again until I can get this fixed.

Setup is O-360A1D with Rotec TBI, Catto 3-blade fixed pitch propeller. Fuel system is per plans, with Van's gascolator on the firewall. Added fuel filter between electric pump and gascolator, is on the cool side of the firewall.

I am leaning toward vapor lock as the cause. Possible fixes - remove gascolator? Have a better filter before it in the system, it currently is only catching water that I missed when sumping the tanks.

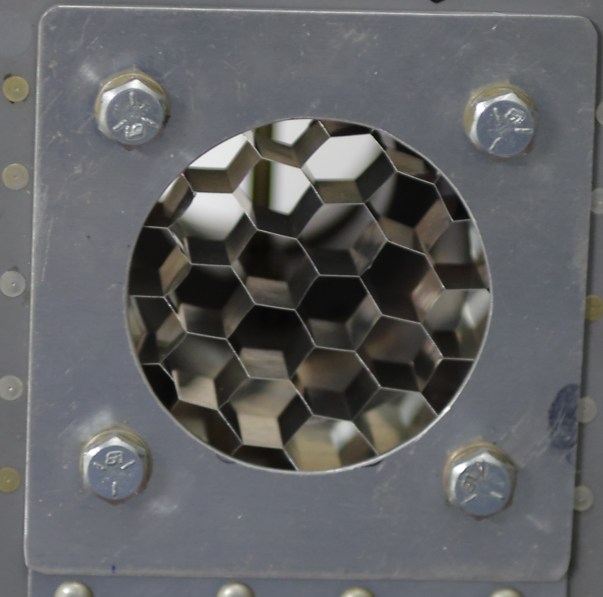

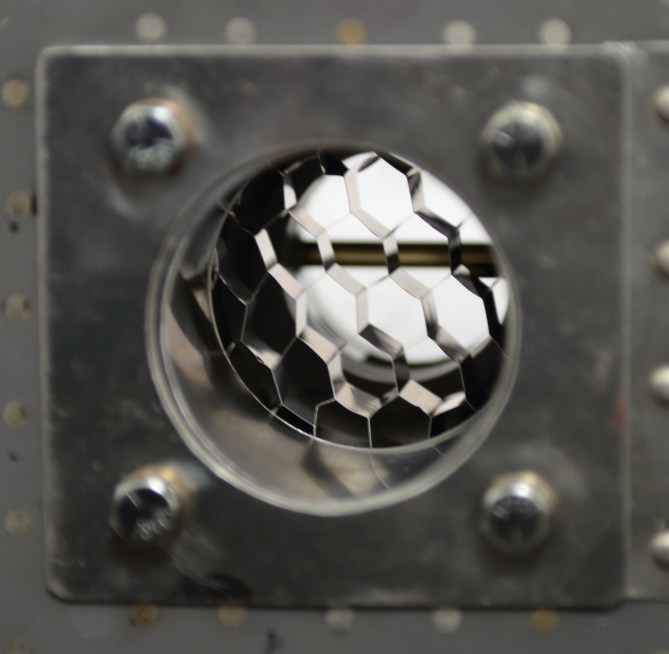

Fuel pump shroud and air line to engine fuel pump?

Also, the fuel line running from the pump to the TBI gets close to the exhaust pipe. I put on a heat shield, but that is probably not enough. Move the exhausts down so they go under the nose wheel mount? Re-route that fuel line so it is longer and less direct (maybe 2-3 inches longer), but farther from the exhaust?

http://user.xmission.com/~bifft/rv/first.htm

On this flight, I did a stall test, and after that the engine wouldn't develop full power. Flew right back and landed. Trying to troubleshoot the problem, found that there was some junk in the throttle body's last chance filter. Thought that this was the cause of the problem. Rotec recommends a 40micron fuel filter, all I had was Van's gascolator.

I suspect I put the dirt into the system when I drained the tanks to fix some leaks. I drained into my old 5 gallon tanks I have used for chainsaw gas, off road trips, etc. Dirt probably came out of there.

So, added a 10 micron fuel filter, cleaned out the lines, flew again. Had the exact same problem. Takeoff and climb out are fine. Slow down to do a stall test, engine won't go back to full power. Can only run below 2000 rpm or so. Fortunately this is plenty to fly back to the airport and land. Inspection found only a few specks in the throttle body filter, a bit more in the larger filter.

Monday went back and flushed out the fuel system. Got a filter funnel (https://www.amazon.com/gp/product/B000SOIRCG) and used the planes fuel pump to pump back into my tanks, using the filter funnel both going into the tanks and back into the plane. Did get some junk in the funnel, including a dead bug. Probably out of my tanks. However the first five gallons and the last five both took 9.5 minutes for a 31 gph flow rate. Should be plenty.

Doing ground running after flushing the tanks everything ran great. However in my many ground runs I had not been able to replicate the problem. After a long ground run trying to simulate a climb out I could get full power. I decided to fly, and closed the hangar, put on my parachute, etc. Engine then would not start. I suspect vapor lock because of the heat soak from the long run. Oil temp and CHT both read 180. It was getting late, so went home.

This morning got out to the airport to try again. There were some delays on the ground waiting for the tower to talk to me, so the taxi out to the runup area took longer than usual, by the video 10:33 after engine start. This time I was able to replicate the problem on runup. Unable to get full power, stopping right around 2000 rpm. Video link goes to just as I am powering up to full throttle.

https://youtu.be/u0DnhU08hEE?t=80

I taxied back and did some more tests near the hangar. After 30 seconds or so with the fuel pump on I could get full power (2200 rpm) after a brief stumble. With the electric pump off, I can't. See later runups in same video:

https://youtu.be/u0DnhU08hEE?t=231

What do people think? What should I try next? Obviously I don't want to fly again until I can get this fixed.

Setup is O-360A1D with Rotec TBI, Catto 3-blade fixed pitch propeller. Fuel system is per plans, with Van's gascolator on the firewall. Added fuel filter between electric pump and gascolator, is on the cool side of the firewall.

I am leaning toward vapor lock as the cause. Possible fixes - remove gascolator? Have a better filter before it in the system, it currently is only catching water that I missed when sumping the tanks.

Fuel pump shroud and air line to engine fuel pump?

Also, the fuel line running from the pump to the TBI gets close to the exhaust pipe. I put on a heat shield, but that is probably not enough. Move the exhausts down so they go under the nose wheel mount? Re-route that fuel line so it is longer and less direct (maybe 2-3 inches longer), but farther from the exhaust?