Your installation story answered one question I had when I received my ASA cowl flap recently. The frame is made to fit into a cowl that is about 1/4" thick. I planned to install mine in the middle of the "coal shovel" exit channel, which is not honeycomb sandwich. It is about 1/16" or less thick. So I was wondering why oh why did Allen make the frame drop in so deep? Whose cowl is so thick? So now I know. In the honeycomb areas, the cowl is apparently about 3/16" thick? so it apparently still took a bit of shim under it, based on your post.

Since I was mounting in much thinner material, rather than have a big layer of build-up on the inside to get the flap flush on the outside, I made a new frame that is just 0.063" thick, and re-assembled the flap on that frame. A spacer was needed under one of the actuation linkage anchor points to keep the actuation geometry working right. It is a fairly clever actuation linkage. With the thin frame, the cowl flap surface was slightly below the cowl surface, so I slathered a layer of epoxy/microballoons over it and then sanded it completely flush. The area where it is installed is not flat, it is convex, so it was going to take some filler to contour in any case.

A couple of other install details:

While I was making the new frame, I noticed that the pivot points were assembled with AN bolts and low profile (AN364) elastic stop nuts. This type of application where the parts are moving and the bolt is not clamped down tight really should have a castle nut with a cotter pin. A minor detail? It is just a cowl flap, after all.

But to reassemble the linkage on the new frame, I had to take all the bolts out of the linkage, and I was surprised to find that the AN bolts were all too short, so that the unthreaded portion (the shank) was not long enough to extend through all the moving parts. At each point in the linkage where two pieces are moving on the pivot bolt, one of the two pieces was entirely moving on the threaded portion of the bolt!

Considering that this linkage will see one full cycle per flight (open for take-off, close for cruise, open again for landing) and in an environment with some soot/grime, this seems really poor to me! The linkage parts are made elegantly lean, meaning not a generous amount of edge clearance on the pivot holes, and then, here they are with a high-wear situation with one of the parts turning on the threads of the pivot bolt! It won't be long before those holes are all worn oval, the flap will not close all the way because the nice linkage will have slop at all the joints from wear. Sorry Allen, but I really think you can do better! I replaced all the AN bolts with proper-length clevis bolts so that the parts are turning on the unthreaded shank, then a washer, a castle nut, and a cotter pin.

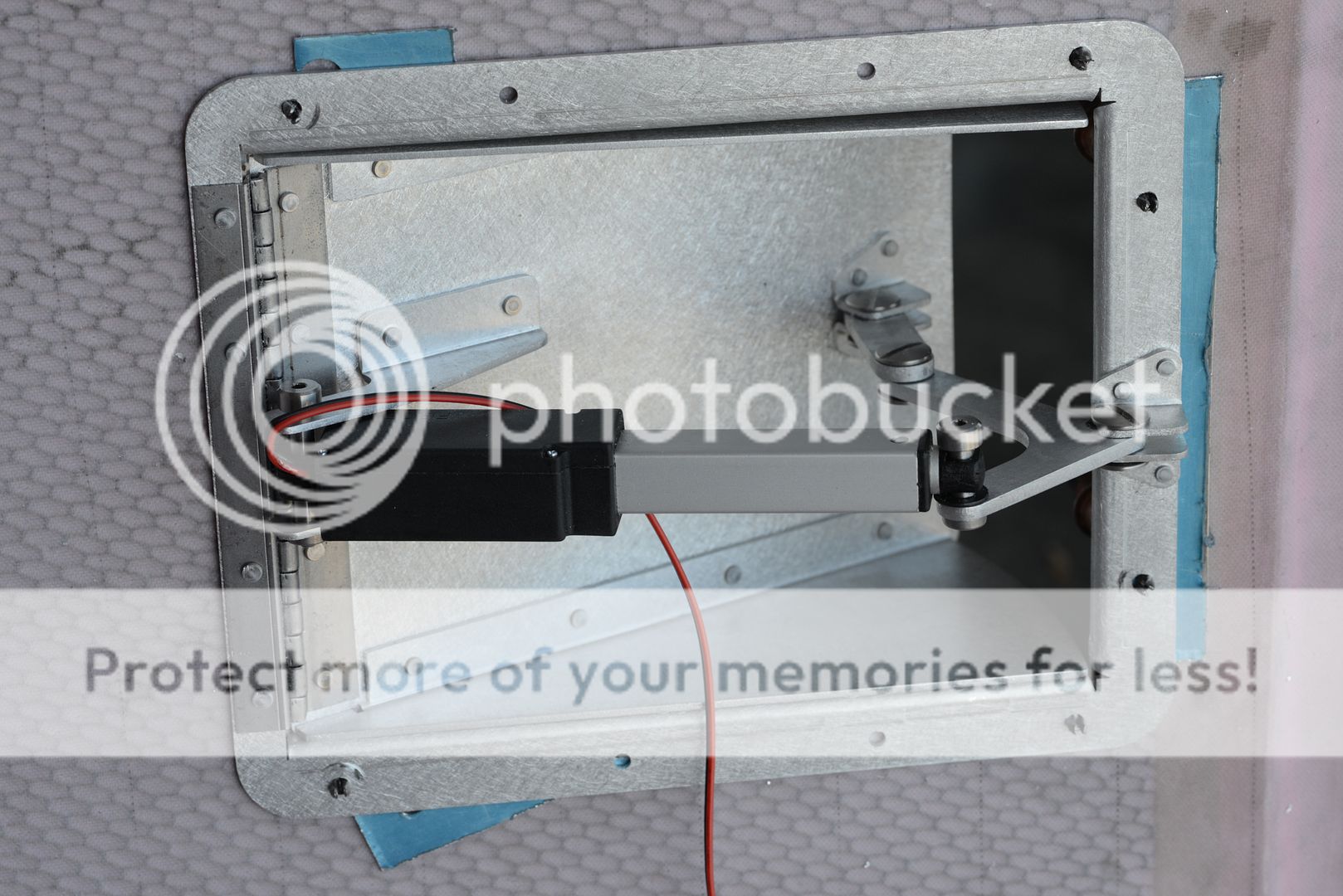

Finally, I totally understand the logic of having the unit all self-contained, with the actuator installed directly on the cowl flap frame. This is desirable from both a manufacturing standpoint and an installation standpoint, where a single drop-in unit really makes it tidy, fast, simple. - BUT -- the actuator itself is positioned right in the area where the flow is accelerating and trying to rush out through the open cowl flap. The actuator constitutes a blockage of over 15% of the net flow area out of the cowl flap! The aerodynamicist in me just couldn't stand for that, so I added a 5" extension shaft on the actuator, and relocated the actuator upstream, where the velocities are slower, both with the flap closed, and with the flap open. This is a fussy detail I admit, and as I said, I understand the logic of having a self-contained unit. But I like this better.

look close you can see the castle nuts on the clevis (pivot) bolts. The extension shaft is a thick-walled 3/8" aluminum tube, threaded at both ends for 8mm x 1.25mm. The actuator shaft is threaded similarly for the black plastic end fitting, which I just moved to the end of the extension tube. the coupling between the original actuator shaft and the extension is just a 1" length of 8mm x 1.25mm bolt, drilled hollow to save a little weight. I ended up needing 2 0.2 mm shim washers between the tubes to get the clocking right, so the end fitting lined up with the linkage. You can also see that I incorporated a radiant-heat shield in the mounting bracket for the actuator, since the whole thing in nestled up among the exhaust pipes. Allen does recommend putting heat shields on the exhaust pipes, that will work too. But this seems tidy.