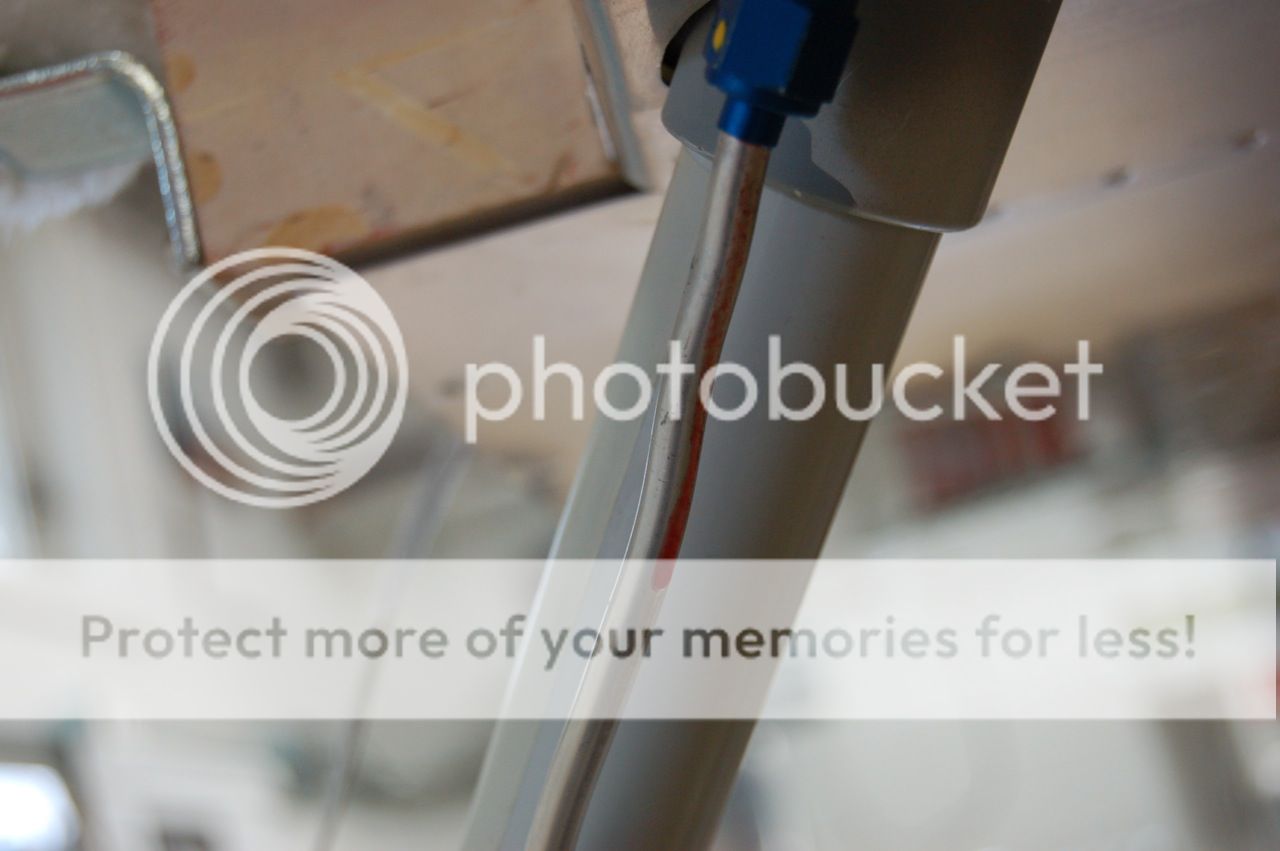

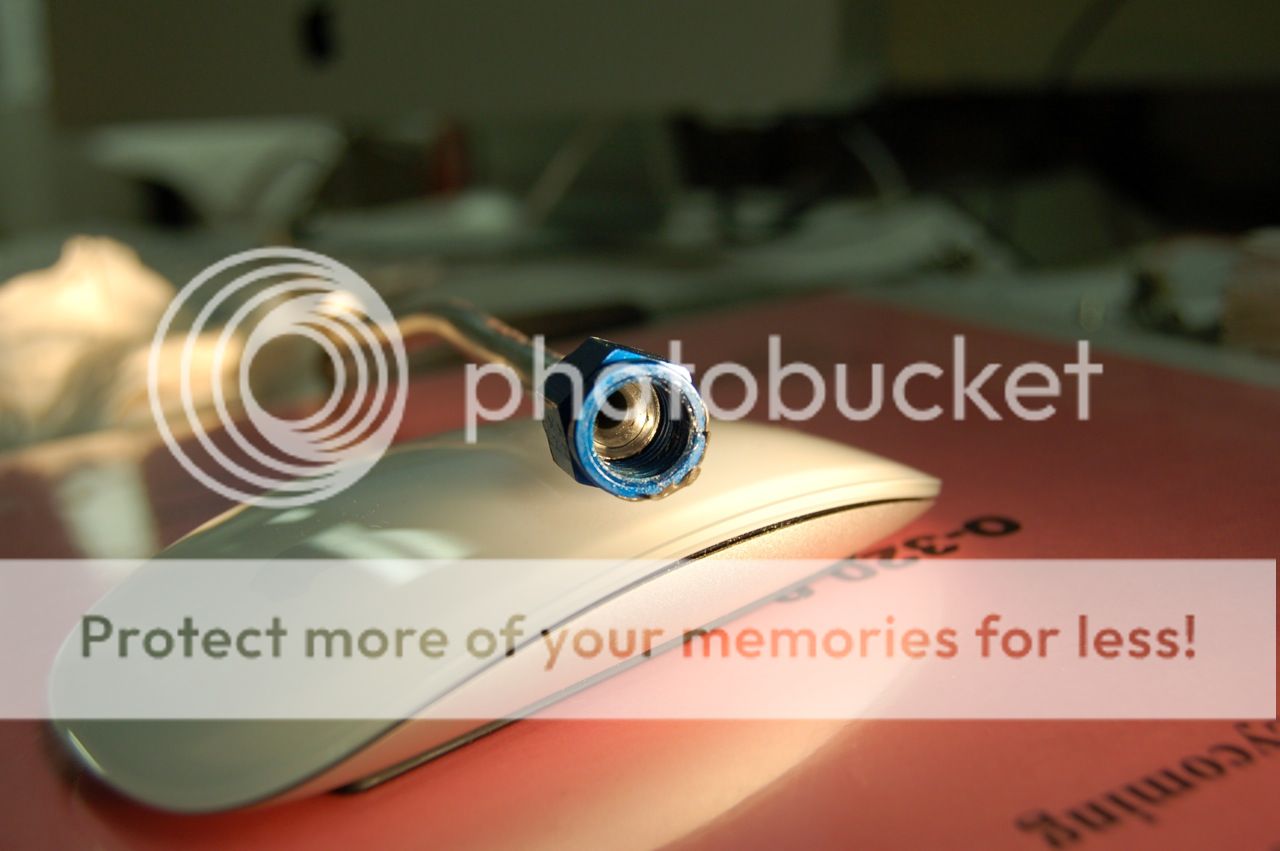

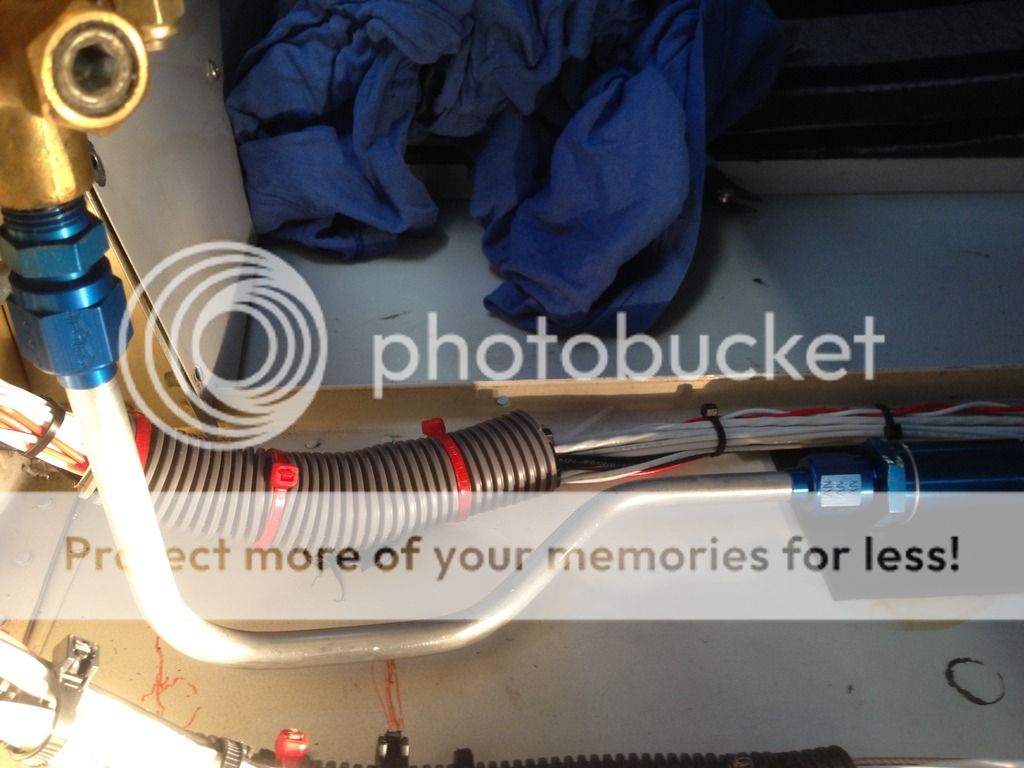

During preflight this morning I caught a faint fuel smell when I opened the canopy, I re-adjusted the seat backs and thought I could still smell a bit of gas. There is a bit of a gap around the fuel selector cover and with a flashlight I thought I could see a bit of moisture. After I removed all the covers and started pumping fuel through the lines I found fuel seeping out the outlet connection of the fuel valve going forward to the fuel filter and fact pump. After removing the fuel line there was no visible crack, after a little bit of prodding I found it.

I literally just finished my first condition inspection, just over an hour flight time since unbuttoned everything up. During the condition inspection there was no sign of any fuel from the previous 96 hours, all connections were tight and I pumped the remaining fuel out of the tanks with the boost pump while everything was opened up looking for leaks.

I remade my original lines prior to final assembly after reading this post several years ago:

http://www.vansairforce.com/community/showthread.php?t=78240

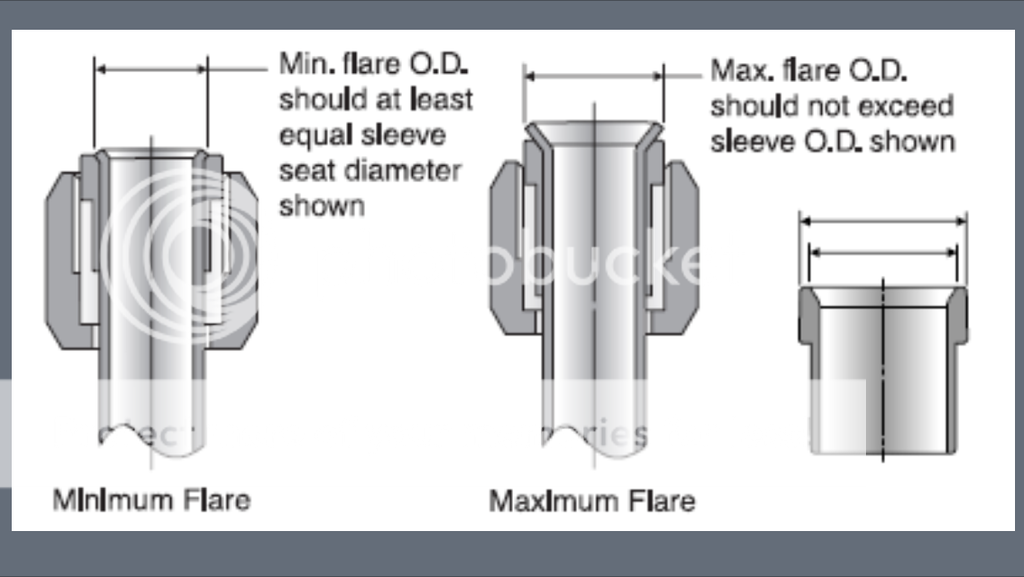

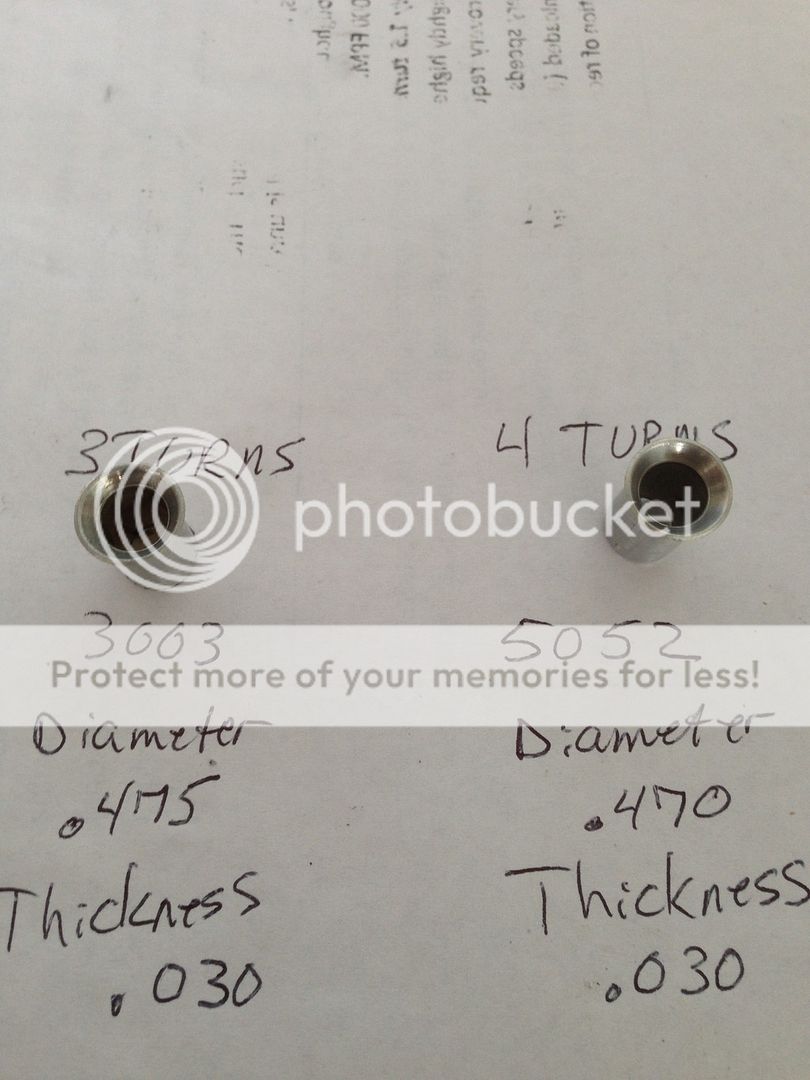

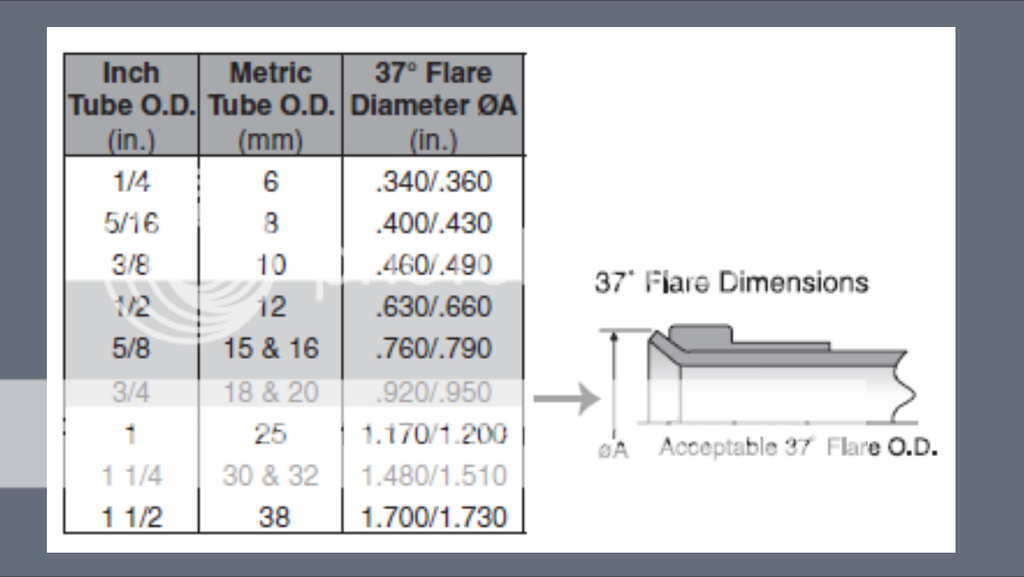

I made the flares with the Rigid RFT37 and this "how to:"

http://www.gen-aircraft-hardware.com/images/pdf/GAHco_Flaring_Stainless_Tubing.pdf

I thought I did a decent job, perhaps not. It is the line I bend slightly to remove my Earls 85 Micron inline fuel filter, is it possible that slight bending of the fuel line without loosening the flare nut on the fuel selector would cause this? I tightened via the Flats From Wrench Resistance charts, did I over tighten it?

Thanks,

Andy

I literally just finished my first condition inspection, just over an hour flight time since unbuttoned everything up. During the condition inspection there was no sign of any fuel from the previous 96 hours, all connections were tight and I pumped the remaining fuel out of the tanks with the boost pump while everything was opened up looking for leaks.

I remade my original lines prior to final assembly after reading this post several years ago:

http://www.vansairforce.com/community/showthread.php?t=78240

I made the flares with the Rigid RFT37 and this "how to:"

http://www.gen-aircraft-hardware.com/images/pdf/GAHco_Flaring_Stainless_Tubing.pdf

I thought I did a decent job, perhaps not. It is the line I bend slightly to remove my Earls 85 Micron inline fuel filter, is it possible that slight bending of the fuel line without loosening the flare nut on the fuel selector would cause this? I tightened via the Flats From Wrench Resistance charts, did I over tighten it?

Thanks,

Andy

Last edited: