Lycoming 4-cyl crank with pendulums, pins, and bushings. They're between the throws for cyls 3 and 4, and positioned 90 degrees to those throws. As such, they cannot counter recip forces. Some other engines do use torsional pendulums in a dual role, recip counterweight and torsional absorber.

From ECI's notes on dynamic crankshaft balancing:

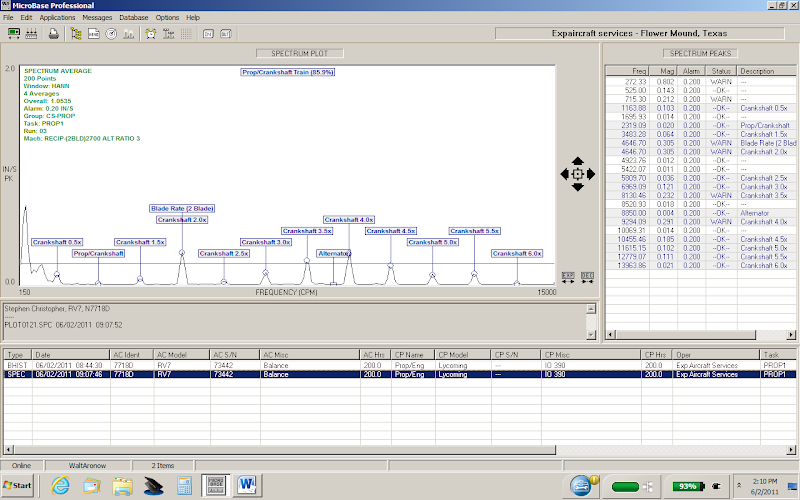

A dynamic

propeller balancer like Walt's uses a single sensor (here in green) mounted to a case bolt just behind the ring gear. It detects acceleration in two axis (X and Y). If the sensor could be mounted precisely on the crankshaft rotational axis, that is

all it would detect, just the linear up-and-down and side-to-side of rotating imbalance (cyan arrows).

However, such a mounting is physically impossible; best we can do is a case split line bolt. That means there is a distance (an arm) between the crank axis and the sensor (here in orange).

The crankshaft/propeller system also vibrates torsionally. Here the system is simplified as two flywheels, one representing the prop and one representing the crank. The propeller mass moment of inertia is many times the inertia of the crankshaft assembly, thus the relative size difference.

Torsional vibration is a twisting of the shaft (the connecting stiffness) between the inertias. The two inertias oscillate in opposite directions, twisting the shaft one way, then reversing and twisting it the other way. We would not even notice torsional vibration in our engines except for one detail; the oscillation of the crank is transmitted to the engine block by the piston sidewalls. The engine block thus vibrates (rocks) around the crankshaft axis as well as in the X and Y axis.

Here's the important part. If the sensor could be magically mounted on the crank center, it would not detect any of the block movements with a torsional source. However, since it is mounted with a arm between the crank center and mount point, its X axis detects both linear and torsional movements, i.e. prop imbalance and torsional block reaction. That is why the balancer can show orders other than the 1st....even though the 1st is the only one that can be balanced with weights on the ring gear or spinner. The detection of other orders is useful, and they may change as rotating balance is adjusted with weights, but they're not a rotating imbalance. They are ghosts of the torsional vibration superimposed on the X axis detection.

Postscript 11/6: Order sensing description is subject to modification; consulting in progress.