...which is a significant plus for either currently available PWM FI system, as compared to constant flow FI.

Which brings us back to the OP's question.

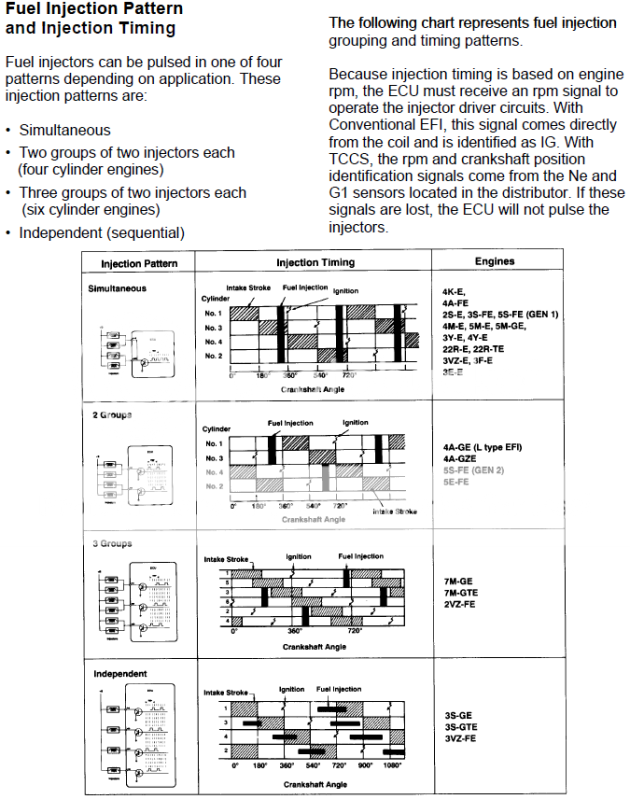

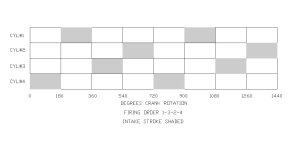

I've attached a semi-sequential injection diagram below, compared to batch injection. If installed on identical engines, either must inject the same fuel quantity for similar power, so the difference here is merely when the injectors are opened. It's probably a good representation of the System 32. If not, I'm sure we would all appreciate a correction. One wildcard, for example, might be injector flow rate, which would change the pulse width.

Take a hard look. Is there an advantage to one or the other, and if so, why?

.

Good work bringing this back on topic.

Sounds like you are trying to decipher what Robert means by, "System32 provides semi-sequential fuel delivery timed to intake valve operation."

I suspect that all that means is that he has a dedicated injector channel for each cyl so he uses the crank position sensor to determine where he thinks the cyl is at in the cycle and injects fuel at a specific time as opposed to once per cycle for all cylinders.

Whether that makes a lick of difference really boils down to two things in my mind:

1. As discussed earlier, how would he be able to determine if we are on the intake or exhaust stroke. Without this information he is blind, so everything else is moot.

2. Even if he did know exactly where the piston is in it's stroke, does the fuel atomize better if it's sprayed on the back of a open or closed valve? In our application, I suspect it matters little.

On his comparison page he mentions a lot of marketing stuff that doesn't really matter, but he also mentions a few things that are nice.

1. Internal data logging to SD card.

2. Software is field updatable.

3. Provisioning head configures both ECUs at the same time.

He also talks about EMI protection and voltage input range, but either of these systems is susceptible to poor aircraft electrical system design.

As for mechanical vs EFI. I think that the real advantage of EFI is in the starting (especially hot starting) of the engine. Mechanical or electronic injector is more or less doing the same thing, especially when the electronic injector is in the same hole as the mechanical one, which is my understanding from both setups.

Ross, when you finally do start on EM-6 a few things that I think you should make better:

1. The three things above.

2. Internal battery fail over like the CPI-2.

3. Enough injector channels for an 8cyl.

4. Wifi access point that allows engine monitoring from any wifi/browser.

The ESP32 microcontrollers are pretty easy to work with, fast, robust and have built in wifi/bluetooth. If you were especially clever, you could provide a link in the web interface to upload all of the config parameters, engine sensors, and system logs directly to you for troubleshooting.

Also, I know you are in love with your website, but many of us aren't. Please consider using a real web framework, fonts, javascript, and other modern web tech that doesn't look like it was written in notepad in 1997.

Matt