Hi all,

I have been dealing with a EGT sag on #2 with a little engine vibration just after startup for a couple of months. Never had an issue beyond a minute or so while first starting the engine until it finally occurred on departure. Under 200 hours on the engine so it was difficult to be aggressive initally.

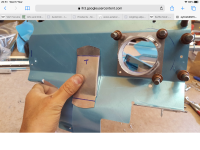

Lycoming recommended approach is SB388 followed by SI1425A. I opted to skip the wobble test and proceed with reaming the valve guide and cleaning the valve stem.

See the photo of the shop towel. Some crud was evident after reaming and pulling the material off the reamer. It is black and does not look like lead. I looked thru and did not find anything solid or metallic valve guide material.

See the black on the valve photo. Is this common finding for sticky valves?

I am a little surprised at how little material caused the sticky valve. I have not yet tested so this conclusion might be premature. So is it me or just stuff happens?

Is this cylinder too hot? Cylinder #2 CHT is the hottest by 30 or 40 degrees. All cylinders are at 320 or so and #2 might be at 350 or 360. I had reduced the size of the original air dam thinking it was causing higher CHT issues. Cylinder 1 and 2 are hottest. Counterintuitively, would adding the original air dam back help reduce temperatures?

Are we having fun?

I have been dealing with a EGT sag on #2 with a little engine vibration just after startup for a couple of months. Never had an issue beyond a minute or so while first starting the engine until it finally occurred on departure. Under 200 hours on the engine so it was difficult to be aggressive initally.

Lycoming recommended approach is SB388 followed by SI1425A. I opted to skip the wobble test and proceed with reaming the valve guide and cleaning the valve stem.

See the photo of the shop towel. Some crud was evident after reaming and pulling the material off the reamer. It is black and does not look like lead. I looked thru and did not find anything solid or metallic valve guide material.

See the black on the valve photo. Is this common finding for sticky valves?

I am a little surprised at how little material caused the sticky valve. I have not yet tested so this conclusion might be premature. So is it me or just stuff happens?

Is this cylinder too hot? Cylinder #2 CHT is the hottest by 30 or 40 degrees. All cylinders are at 320 or so and #2 might be at 350 or 360. I had reduced the size of the original air dam thinking it was causing higher CHT issues. Cylinder 1 and 2 are hottest. Counterintuitively, would adding the original air dam back help reduce temperatures?

Are we having fun?