this is fun

After studying the drawings Van?s sent me, I decided to go ahead on the end after all. I used a 1 3/8th hole saw. It gave me plenty of room to see everything, and get either a small socket or box end in there with no problem. Both work quite well, only really need one or the other.

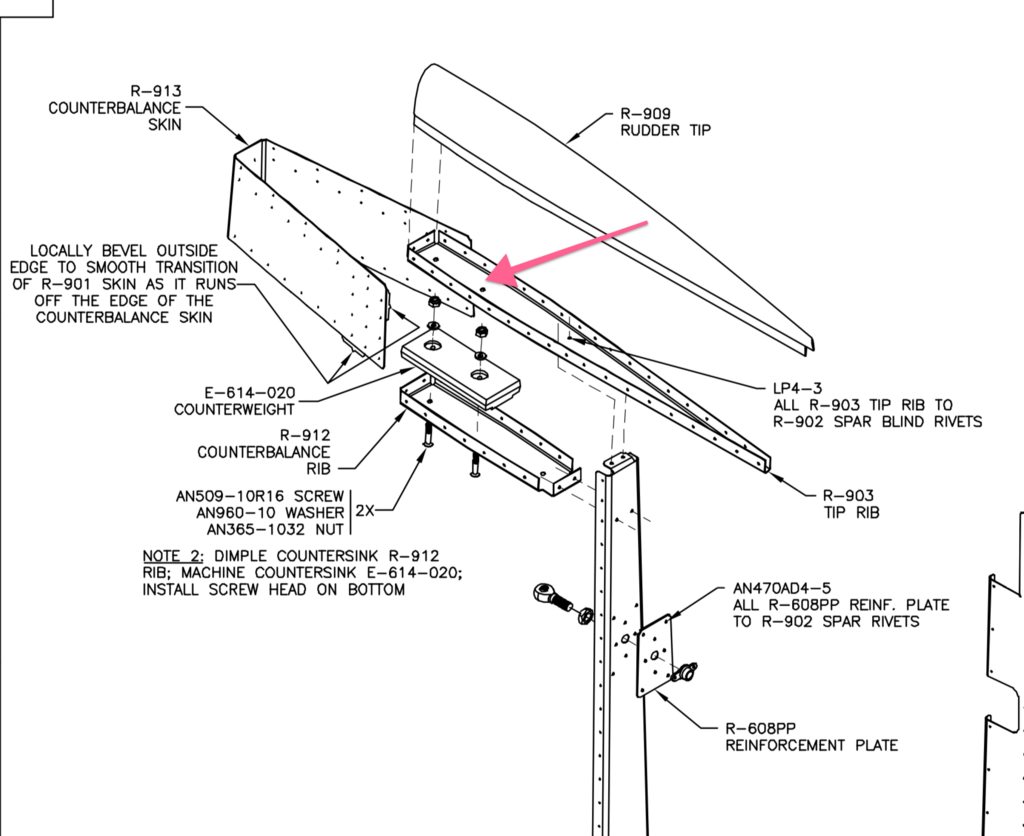

I didn?t see any problems on what could have caused these two nuts to back out. They were the locknuts that were supposed to be on them. Both had the washers. I tightened them all back down at first, to see if they would, and they did. Then took the bolts, washers and nuts all out to look at it some more. I used strong hand pressure to see if the locknut could go on that way, but it was still tight, and wouldn?t go any further after a few turns indicating to me the locknuts are still just fine. This 8 rudder is only 4 years old, and probably doesn?t have 200 hours on it. As another suggested, I did check to see if the lead weight was resting on any rivet. It wasn?t, it was nice and flat. The nuts still had threads to spare on the bolts, so they weren't bottomed out.

Neal, what red stuff are you referring too? The red silicone I have in the pic? Should I cover the top of the threads and nut with it after I use some Loctite or equivalent on threads too?

Here are the tools I used along with a few other things.

If you?re wondering what the magnets are for, well, here goes.

The nut to the back bolt fell off, and there was a very small opening at the rear where it fell down further into the rudder. It went completely out of sight. I located it about 6? further down into the rudder before it caught on the stiffener. I knew it was there, because I would take my magnet, and it would rattle around. Since the plane is aluminum and non-magnetic, and the nut was magnetic, I was only picking up on it.

I took the long claw pick that has magnets on it (Harbor Freight, best $2.00 I ever spent) and placed it horizontally as far as it would go in the opening I cut and let it rest there. I then took the machinists magnetic base and put it between my plane and a piece of paper to keep from scratching my paint. I slowly wriggled it back up to the top, hoping I could get it to stick to the other magnet pick up. The magnetic base has a on and off switch which I turned off when at top hoping it would catch on the other magnet. I didn?t hear anything drop back down. Went to gently pull the magnetic claw pick out, and sure enough the nut was on there! I got it out the first try! Man that was fun! I rarely get that lucky.

Even if I wasn?t able to retrieve it with the magnet, it was still loose in there, and I could have took off the three nuts to the rudder, then undo the tail wheel clips, pulled the whole thing out, turned it upside down, and shake it out that way.

I?m showing the other 150 lb magnet from Harbor Freight in the pic to show you that one that didn?t work. The force was too spread out to lift the nut, but the other one shown you can also get at HF works great, and has plenty of lifting power along with a on and off switch which I think helps keep your object from being lost again, by gently releasing the magnetic force.

Now just wondering if I should re-use the same nuts, or go with two new locknuts? For extra insurance I?m going to use something like threadlock no 71 which I already have, unless others advise against it and instead think I should go with Loctite. I?d use it if I could find it locally. I?ll just have to order through mail and wait a week or so to get it.

I hope this helps others, and do your Vanhead friends a favor, and remind them to check those two bolts each time on every preflight. Nobody will ever have to remind me.