What I ended up doing...

Les was kind enough to provide me with some additional instructions.

For those of you who follow, here is what I ended up doing:

Well,

I bought an S-1-10 Hartzell governor from Vans.

The instructions that came with the VA-153 Cable bracket looked like they were written for the MT governor, so I posted some questions here, and got some suggestions on how to install the bracket.

Long story short, they way my governor arrived, it was impossible to get the bearing/bolt onto the actuator arm as Vans drawings indicated.

No way that bolt is going in.

Here is the orientation of the governer actuator as recieved:

Notice that if the arm swings left, the bearing and bolt are going to strike that stop screw holder...

This is where the instructions come into play, they tell you to loosen the six cap screws so that you can rotate the governor head. Well, if you have never seen inside of a governor, you have to wonder...am I screwing up this thing's calibration?

The Hartzell folks (Thank you Les) were kind enough to send me some instructions on loosening these cap screws and installing the bracket.

I also called Hartzell technical support, and they were VERY helpful in talking me through this.

A couple of things to note:

The drawings will most likely NOT match the way your arm is positioned on your governor.

Rule 1:

The clock orientation of the arm can be changed. It will NOT mess up the governor's calibration.

Rule 2:

When you loosen those screws and rotate the head, you MIGHT dislodge the O-Ring on the governor head.

I did...I almost didn't notice it when I was about to tighten those screws back in. That would have been bad.

Rule 3:

The governor WILL NOT EXPLODE if you completely remove all six scews and gently remove the head to reseat and check that O-Ring.

This is what it looks like inside:

OK, the important things are:

1: If your control arm travel sweeps by the bosses that mount the stop screws like in the first picture, you will need to loosen the nut holding the arm down so that you can lift it on the shaft and rotate it so that it can travel fully without the rod end bearing/bolt hitting anything. See picture below...notice the arm has been relocated by about 90 degrees compared to the first picture above. Remember to re-torque that nut properly.

2: In order to orient the bracket correctly, it must be pointing towards your control cable. In my installation, the cable is coming into the governor from the left, and below by about 45 degrees. That large governor bolt at the rear in the picture below is at about the correct orientation if the governor is on the engine. So the arm is pointing at about 12 o-clock to get full travel from the control cable.

3: You will NOT be able to get the bolt and bearing on with the bracket in place, so temporarily attach it to see how everything works

If you leave the bracket off, you can get the bolt in....

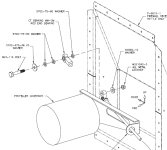

Here is what the bracket looks like in place and configured so that everything clears, and the arm can move full travel freely. Note the bracket is pointing away from the large bolt on the governor. Also note that the control rod will be able to move full travel freely. (This control rod is a temporary rod used for fitting, it is NOT a control cable)

Here is is in place on the engine.

The rod is pointing down at about 45 degress.

Here is the control cable where it will be placed.

Note, I am going to have to attach the cable to the bracket, then the cable/ rod end to the governor actuator arm, THEN finally the bracket to the governor. Hartzell recommends the use of threadlocker primer, then Loctite 242 on those cap screws when they are reinserted .

Thats it. Hope this helps someone else.