Richard RG

Active Member

Greetings all,

Little did I know the resources available to a new RV owner. Amazing! I've searched high and low in the various forums and not able to find a definitive answer to my question. Please bare with me while I give a little back ground leading up to my question (s).

Late in the summer of 2020 I became the proud owner of an especially well built RV3b, ident C-GBGF and completed in 2009. I purchased the RV3 from the widow of the craftsman that built it, her husband and builder having died in his C-172. He was flying off the west coast of Vancouver Island, British Columbia, gathering weather information data for NOAA.

The RV3 was his third RV build. His lovely widow knew nothing of the RV3, but after a 5 hour inspection by both myself and a very competent Aircraft Maintenance Engineer (AME) determined the aircraft to be exceptionally well put together and seemingly, strictly built to Vans construction plans.

Having zero tail wheel time when I bought the RV3, discovered its not so easy to get transition training. Fast forward 5 months... I finally got 1.1 hours in an RV6, with a most excellent instructor. I think we spent a bit more of that time doing aerobatics, rather than figuring out how to taxi and land.

During the taxi training phase of my 1.1 hours, discovered the RV6 was a lot more manageable than the RV3, which I had taxied around a number of times. Upon return to home base from my first tail wheel adventure, quickly determined that the tail wheel assembly was pretty much worn out on the RV3. More weeks passed, waiting for the new tail wheel assembly to arrive and install.

Once the RV3 was good to go, intended to resume training in the RV6 but then discovered the left starting mag was dying in my C-150 aerobat, not to mention the transponder started giving me grief as well. The transponder is mandatory in order to fly to the RV6.

Yet more weeks pass and I'm itching to fly the RV, but paranoid about breaking it. Lucky for me, some airport friends took pity and volunteered I could use a Piper Tri-Pacer converted to tail dragger, to carry on learning how to manage a tail dragger.

A very brave and competent fellow jumped into the converted Tri-pacer with me and even more bravely, gave me the left seat with no brakes on his side. After 3 hours of flying around and doing a bunch of landings/takeoffs he announced that I should go fly the RV. I didn't necessarily agree with him, but threw caution to the wind and strapped into the little hotrod, lined up on the runway and with knees shaking, did the most horrendous takeoff I've ever done. I've got 900 hours total, 450 of that in a Mooney M20e and the rest in 150's.

That first takeoff was quite an eye opener! That little sucker has some serious get up and go and will not be nice to you if you pick the tail up real fast. I picked the tail up real fast and it was immediately doing a hard left... I ended up doing a bit of the wild thing down the runway using an awful lot of the 75' width and yep, I had a wee bit of an audience, of course.

Luckily, the RV3 gets in the air very quickly, so managed to get away quickly from my bad takeoff roll and the prying eyes of the seasoned pilots watching my performance. Happily, they didn't have their score cards handy that day. Scoring visiting pilots is a bit of a pass time at our 2400' runway. The Ukrainian judges as they call themselves have score cards that only go to 7, so don't feel bad if you get a 5 or 6.

After an hour of slow flight, some stalls and feeling the plane out, it was time to land. During my hour of feeling the plane out, I switched tanks after about a half hour. Same as the Mooney, always put the boost pump on during the switch and watch the fuel pressure. Boost pump off, watch the pressure.

My first approaches were intentional overshoots, several times. It certainly doesn't take much to execute an overshoot in a little airplane that weighs 821 Lbs, with a 160hp.

Satisfied with the overshoots ,was time to land. Sitting on the ground, I can see pretty much nothing looking forward. So, having memorized this sight picture before takeoff, knew that if my butt was almost dragging on the ground and I could see virtually nothing looking forward, I should be touching down very gently soon. Things worked out a little differently than I hoped. It seems that spring gear can be pretty springy, unless you set those springs down very gently. Apparently I wasn't gentle enough... after the second bounce that was about the same altitude as the first, thought things weren't going to get any better, so powered up and went around. That little RV does a go around really well!

Though I still bounce somewhat, after a grand total of twelve hours of flying the RV3, find that the airplane manages itself just fine if the stick is held full back and you keep it pointed straight. I've actually surprised myself with several greasers, but attribute that more to luck than skill.

Of course, after each flight I very carefully check and calculate fuel consumption because I have never trusted fuel gauges. Early in the process of monitoring the fuel burn, I was shocked a couple of times to discover that the Port tank had come up in level, rather than going down the expected amount. Further, the Starboard tank would be very much lower than expected. In my books, this is very odd and potentially hazardous to ones health and longevity.

Shortly after taking ownership of the RV I discovered that the lever attached to the fuel selector shaft was slightly loose. I applied locktite to the screw that attaches the fuel lever selector to the fuel selector shaft but still felt a small amount of play in this assembly. Looking closer, I could see a small amount of wear between the fuel lever selector socket face and the corresponding profile on the end of the fuel selector shaft. The aircraft has 840 hours on the airframe and likely the same hours on the fuel selector. It appears to be the selector that came with the kit, so have ordered a replacement from ACS and not nearly as expensive as the Andair unit.

When I discovered the unusual tank levels in the RV, suspected that the fuel valve was the culprit and some how cross feeding. It didn't make sense that the the Port (left) tank was always gaining level over the Starboard tank. Right from the first flight in the RV, my habit was to always begin flight with full tanks and always start up and run on the right tank, switching later in flight.

After my most recent flight, filled both tanks full and taxied back to the hanger. When I shut down, I had a pretty big puddle of fuel under the left tank vent. I opened the left tank cap and fuel overflowed from the tank. It finally became clear that something seriously strange was going on with the fuel system.

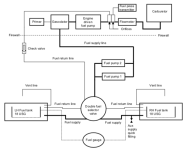

A close inspection of the fuel system revealed a return fuel line tied in off the main fuel supply line, immediately prior to the carburetor, . The previous owner had installed what appears to be a recirculation line off the fuel supply to the carburetor and is returned to the left tank only.

I am assuming such a line is installed to minimize the chance of vapor lock and also, helps to ensure cool fuel is being delivered to the engine.

My understanding is the previous owner may have used mogas/car gas. In the accident investigation related to his crash in the C-172 it was noted that there was a mix of avgas and mogas in his aircraft and carb ice may have been a contributing factor to the accident.

This recirculation line complicates managing fuel and at this time, I am trying calculate the recirculation rate. So far, I believe there is no restriction orifice in the recirculation line, as even after 40 minutes of drawing down the full left tank in flight and then switching to the right tank for 30 minutes, discover on the ground that the left tank is again full to the max.

At this time, I don't have plans to burn mogas after having had a fright in the Aerobat when using mogas. Very hot day in the Aerobat, climbing out over very inhospitable terrain and the engine starts dying, seriously no fun.

Fortunately, the Aerobat has a 150hp lycoming and requires a boost pump for this STC. The boost pump saved my bacon that day and have shied away from mogas ever since.

Am I on the right track assuming this return line is for vapor lock control? Can I install an isolation valve on this return line to the left tank and open only as required? Will shutting off this return line cause issues with the mechanical double diaphragm fuel pump attached to the back side of the Lycoming E2D?

Would I be better off to install a restriction orifice in the return line (if there isn't one) which should then allow a metered and easily measured amount of fuel recirculation?

Apologies for such a long post, just thought I'd give some back ground before putting my question out there. Any insights to managing my fuel in the safest manner possible, much appreciated!

Little did I know the resources available to a new RV owner. Amazing! I've searched high and low in the various forums and not able to find a definitive answer to my question. Please bare with me while I give a little back ground leading up to my question (s).

Late in the summer of 2020 I became the proud owner of an especially well built RV3b, ident C-GBGF and completed in 2009. I purchased the RV3 from the widow of the craftsman that built it, her husband and builder having died in his C-172. He was flying off the west coast of Vancouver Island, British Columbia, gathering weather information data for NOAA.

The RV3 was his third RV build. His lovely widow knew nothing of the RV3, but after a 5 hour inspection by both myself and a very competent Aircraft Maintenance Engineer (AME) determined the aircraft to be exceptionally well put together and seemingly, strictly built to Vans construction plans.

Having zero tail wheel time when I bought the RV3, discovered its not so easy to get transition training. Fast forward 5 months... I finally got 1.1 hours in an RV6, with a most excellent instructor. I think we spent a bit more of that time doing aerobatics, rather than figuring out how to taxi and land.

During the taxi training phase of my 1.1 hours, discovered the RV6 was a lot more manageable than the RV3, which I had taxied around a number of times. Upon return to home base from my first tail wheel adventure, quickly determined that the tail wheel assembly was pretty much worn out on the RV3. More weeks passed, waiting for the new tail wheel assembly to arrive and install.

Once the RV3 was good to go, intended to resume training in the RV6 but then discovered the left starting mag was dying in my C-150 aerobat, not to mention the transponder started giving me grief as well. The transponder is mandatory in order to fly to the RV6.

Yet more weeks pass and I'm itching to fly the RV, but paranoid about breaking it. Lucky for me, some airport friends took pity and volunteered I could use a Piper Tri-Pacer converted to tail dragger, to carry on learning how to manage a tail dragger.

A very brave and competent fellow jumped into the converted Tri-pacer with me and even more bravely, gave me the left seat with no brakes on his side. After 3 hours of flying around and doing a bunch of landings/takeoffs he announced that I should go fly the RV. I didn't necessarily agree with him, but threw caution to the wind and strapped into the little hotrod, lined up on the runway and with knees shaking, did the most horrendous takeoff I've ever done. I've got 900 hours total, 450 of that in a Mooney M20e and the rest in 150's.

That first takeoff was quite an eye opener! That little sucker has some serious get up and go and will not be nice to you if you pick the tail up real fast. I picked the tail up real fast and it was immediately doing a hard left... I ended up doing a bit of the wild thing down the runway using an awful lot of the 75' width and yep, I had a wee bit of an audience, of course.

Luckily, the RV3 gets in the air very quickly, so managed to get away quickly from my bad takeoff roll and the prying eyes of the seasoned pilots watching my performance. Happily, they didn't have their score cards handy that day. Scoring visiting pilots is a bit of a pass time at our 2400' runway. The Ukrainian judges as they call themselves have score cards that only go to 7, so don't feel bad if you get a 5 or 6.

After an hour of slow flight, some stalls and feeling the plane out, it was time to land. During my hour of feeling the plane out, I switched tanks after about a half hour. Same as the Mooney, always put the boost pump on during the switch and watch the fuel pressure. Boost pump off, watch the pressure.

My first approaches were intentional overshoots, several times. It certainly doesn't take much to execute an overshoot in a little airplane that weighs 821 Lbs, with a 160hp.

Satisfied with the overshoots ,was time to land. Sitting on the ground, I can see pretty much nothing looking forward. So, having memorized this sight picture before takeoff, knew that if my butt was almost dragging on the ground and I could see virtually nothing looking forward, I should be touching down very gently soon. Things worked out a little differently than I hoped. It seems that spring gear can be pretty springy, unless you set those springs down very gently. Apparently I wasn't gentle enough... after the second bounce that was about the same altitude as the first, thought things weren't going to get any better, so powered up and went around. That little RV does a go around really well!

Though I still bounce somewhat, after a grand total of twelve hours of flying the RV3, find that the airplane manages itself just fine if the stick is held full back and you keep it pointed straight. I've actually surprised myself with several greasers, but attribute that more to luck than skill.

Of course, after each flight I very carefully check and calculate fuel consumption because I have never trusted fuel gauges. Early in the process of monitoring the fuel burn, I was shocked a couple of times to discover that the Port tank had come up in level, rather than going down the expected amount. Further, the Starboard tank would be very much lower than expected. In my books, this is very odd and potentially hazardous to ones health and longevity.

Shortly after taking ownership of the RV I discovered that the lever attached to the fuel selector shaft was slightly loose. I applied locktite to the screw that attaches the fuel lever selector to the fuel selector shaft but still felt a small amount of play in this assembly. Looking closer, I could see a small amount of wear between the fuel lever selector socket face and the corresponding profile on the end of the fuel selector shaft. The aircraft has 840 hours on the airframe and likely the same hours on the fuel selector. It appears to be the selector that came with the kit, so have ordered a replacement from ACS and not nearly as expensive as the Andair unit.

When I discovered the unusual tank levels in the RV, suspected that the fuel valve was the culprit and some how cross feeding. It didn't make sense that the the Port (left) tank was always gaining level over the Starboard tank. Right from the first flight in the RV, my habit was to always begin flight with full tanks and always start up and run on the right tank, switching later in flight.

After my most recent flight, filled both tanks full and taxied back to the hanger. When I shut down, I had a pretty big puddle of fuel under the left tank vent. I opened the left tank cap and fuel overflowed from the tank. It finally became clear that something seriously strange was going on with the fuel system.

A close inspection of the fuel system revealed a return fuel line tied in off the main fuel supply line, immediately prior to the carburetor, . The previous owner had installed what appears to be a recirculation line off the fuel supply to the carburetor and is returned to the left tank only.

I am assuming such a line is installed to minimize the chance of vapor lock and also, helps to ensure cool fuel is being delivered to the engine.

My understanding is the previous owner may have used mogas/car gas. In the accident investigation related to his crash in the C-172 it was noted that there was a mix of avgas and mogas in his aircraft and carb ice may have been a contributing factor to the accident.

This recirculation line complicates managing fuel and at this time, I am trying calculate the recirculation rate. So far, I believe there is no restriction orifice in the recirculation line, as even after 40 minutes of drawing down the full left tank in flight and then switching to the right tank for 30 minutes, discover on the ground that the left tank is again full to the max.

At this time, I don't have plans to burn mogas after having had a fright in the Aerobat when using mogas. Very hot day in the Aerobat, climbing out over very inhospitable terrain and the engine starts dying, seriously no fun.

Fortunately, the Aerobat has a 150hp lycoming and requires a boost pump for this STC. The boost pump saved my bacon that day and have shied away from mogas ever since.

Am I on the right track assuming this return line is for vapor lock control? Can I install an isolation valve on this return line to the left tank and open only as required? Will shutting off this return line cause issues with the mechanical double diaphragm fuel pump attached to the back side of the Lycoming E2D?

Would I be better off to install a restriction orifice in the return line (if there isn't one) which should then allow a metered and easily measured amount of fuel recirculation?

Apologies for such a long post, just thought I'd give some back ground before putting my question out there. Any insights to managing my fuel in the safest manner possible, much appreciated!