Florida Boy

Member

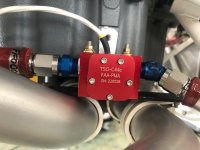

I'm not too thrilled about the mounting location and method for the FT60 transducer as shown in the plans. It is to be mounted on two large hose clamps around the intake pipes on the lower left side next to the oil sump. I think there must be a better way to install the device. I've read that others have moved it up near the divider, but would rather avoid new lines, etc.

I'll try to attach two pictures of the Plans recommended install, but just in case they don't come through, here is the question:

Just behind the transducer, on the left side of the oil sump, there are two drilled and tapped holes with a machined mounting surface that was designed for something (?) by Lycoming. Why not make a bracket secured into the two holes to support the transducer? Has anyone tried that method?

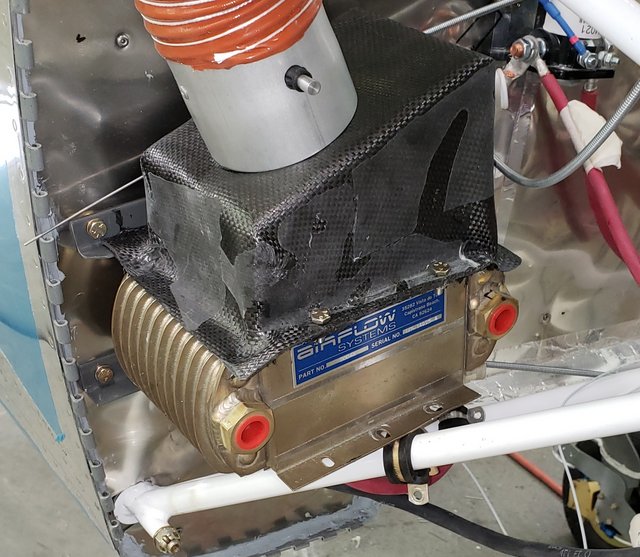

By the way, Raven (makers of inverted oil systems) tells me they've never seen this particular design sump and are puzzled as to how they could build an inverted oil system to fit it. Any experience, or anybody know if Lycoming is using someone to build this sump design for them?

I'll try to attach two pictures of the Plans recommended install, but just in case they don't come through, here is the question:

Just behind the transducer, on the left side of the oil sump, there are two drilled and tapped holes with a machined mounting surface that was designed for something (?) by Lycoming. Why not make a bracket secured into the two holes to support the transducer? Has anyone tried that method?

By the way, Raven (makers of inverted oil systems) tells me they've never seen this particular design sump and are puzzled as to how they could build an inverted oil system to fit it. Any experience, or anybody know if Lycoming is using someone to build this sump design for them?