Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

crankshaft pitting

- Thread starter Jslow2

- Start date

Pitted Thrust Face

Pretty bad. Definitely not airworthy in the Certified world. That is the thrust surface for a tractor configured engine, the prop is always pulling the crank against that surface. Having said that I have seen guys run pitted cranks like that in experimental’s. Likely hood of failure is very low in my opinion but it’s not what I would recommend. You can do some minimal grinding in this area depending on your thrust clearance. Wouldn’t hurt to have AEA out of Dallas take a look and see what they can do for you.

Pretty bad. Definitely not airworthy in the Certified world. That is the thrust surface for a tractor configured engine, the prop is always pulling the crank against that surface. Having said that I have seen guys run pitted cranks like that in experimental’s. Likely hood of failure is very low in my opinion but it’s not what I would recommend. You can do some minimal grinding in this area depending on your thrust clearance. Wouldn’t hurt to have AEA out of Dallas take a look and see what they can do for you.

Last edited:

Pretty bad. Definitely not airworthy in the Certified world. That is the thrust surface for a tractor configured engine, the prop is always pulling the crank against that surface. Having said that I have seen guys run pitted cranks like that in experimental’s. Likely hood of failure is very low in my opinion but it’s not what I would recommend. You can do some minimal grinding in this area depending on your thrust clearance. Wouldn’t hurt to have AEA out of Dallas take a look and see what they can do for you.

+1

As long as the pitting doesn't extend into the radius area, it seems the likelihood of catastrophic failure is pretty low. I believe it is a low stress area. That said, I don't think I would return it to service as is. I vaguely remember the thrust clearance range as around 20-25 thou or so and it's likely you're already in the middle of the range. Based upon the pics, those pits seem too deep to machine down and meet clearance specs.

One option is to have ASA machine it down and give you a new spec. Then see if Divco will build up the matting area on the case and machine back to a custom spec that gives your crank the proper thrust clearance. There is no thrust bearing on the case. It just rides against a machined part of the case. This would make your parts a one off that wouldn't work in any other combination, but worth considering given the crazy cost of crankshafts. I suspect that neither shop will machine to any tolerances other than whats in the Lyc manual though without a lot of pushing.

Last edited:

georgedouglas

Active Member

Guys, in my opinion this crank is not even suitable for an airboat. Why would anyone even think about using a crankshaft this bad in anything that leaves the ground. I know what new crankshafts cost, as I had to buy a new one last year for $4900.00. george

BillL

Well Known Member

i wonder how many of us are flying around with similar crankshaft pitting, not knowing there is any.

besides splitting the crankcase... how to detect that? could surface pitting be seen as debis in the filter?

Since it is corrosion, I suspect oil samples would have shown some thrust bearing materials from erosion after the corrosion events. Also if it is significant wear, the axial movement of the crank (dial indicator) would measure the increased clearance.

One might also expect small shiny particles in the filter, but only an analysis would link it to a bearing. I don't know what the construction of the thrust bearings are, but suspect, lead/tin overlay, copper barrier layer and aluminum body and possibly a steel shell.

It would be odd to see corrosion isolated to just the thrust surfaces, I would expect to see evidence widely in the crankcase.

IMO, it is worth sending the crank for inspection as a minimum as pitting can greatly reduce fatigue life, but certainly not use it as-is. Why? Not because I know, but because I don't know.

Last edited:

rocketbob

Well Known Member

There's a lot of going off in the weeds here. To answer the question "how bad is this", one has to first measure.

The only way to accurately measure this is on a granite surface plate using a shim and a height gage.

Pitting is usually a few tenths deep but just keep in mind what you see now may not be what gets revealed after grinding.

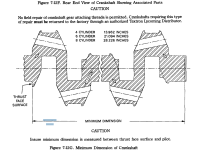

In this case the minimum dimension for the thrust face to the rear crankshaft gear face is 13.962".

Knowing how much "meat" is left will give you an idea if the thrust face can be cleaned up.

Also consider if there is any thrust face wear in the crankcase and how grinding the thrust face on the crank will affect the slinger clearance.

The only way to accurately measure this is on a granite surface plate using a shim and a height gage.

Pitting is usually a few tenths deep but just keep in mind what you see now may not be what gets revealed after grinding.

In this case the minimum dimension for the thrust face to the rear crankshaft gear face is 13.962".

Knowing how much "meat" is left will give you an idea if the thrust face can be cleaned up.

Also consider if there is any thrust face wear in the crankcase and how grinding the thrust face on the crank will affect the slinger clearance.

Attachments

Last edited:

MacCool

Well Known Member

i wonder how many of us are flying around with similar crankshaft pitting, not knowing there is any.

besides splitting the crankcase... how to detect that? could surface pitting be seen as debis in the filter?

Interesting point...hidden corrosion like that is one of my Great Fears. Is crankshaft failure at that thrust surface a common cause of catastrophic engine failure?

to answer the OP's question...

remembering the metallurgy lectures i got when i looked 25 years younger and 25 kg lighter...

i am not the designer of the crankshaft but i believe that our crankshafts are made of soft and flexible steel alloy, surrounded by a hardened surface. to harden a steel surface you implement carbon atoms into the crystalstructure of the metal. these carbon atoms usually don't go very deep into the alloy, so corrosion and pitting could easaly eat in deeper then the hardened surface actually is. that could (most likely) affect everything including strength, fatique life and corrosion resistance. all these parameters, carefully engineered by the manufacturer, are kinda important when it comes to crankshafts of aircraft engines.

grinding/sanding away these spots will most likely not improve anything.

another thing with pitting is that it will never get better. if you reuse the crankshaft it could become much worse in a matter of minutes/hours.

long story short: this crankshaft has to see some really knowledgable expert on the topic before any further use. your local AP will usually not be sufficient enough to make a solid judgement.

but that's all my very personal opinion only.

remembering the metallurgy lectures i got when i looked 25 years younger and 25 kg lighter...

i am not the designer of the crankshaft but i believe that our crankshafts are made of soft and flexible steel alloy, surrounded by a hardened surface. to harden a steel surface you implement carbon atoms into the crystalstructure of the metal. these carbon atoms usually don't go very deep into the alloy, so corrosion and pitting could easaly eat in deeper then the hardened surface actually is. that could (most likely) affect everything including strength, fatique life and corrosion resistance. all these parameters, carefully engineered by the manufacturer, are kinda important when it comes to crankshafts of aircraft engines.

grinding/sanding away these spots will most likely not improve anything.

another thing with pitting is that it will never get better. if you reuse the crankshaft it could become much worse in a matter of minutes/hours.

long story short: this crankshaft has to see some really knowledgable expert on the topic before any further use. your local AP will usually not be sufficient enough to make a solid judgement.

but that's all my very personal opinion only.

Last edited:

to answer the OP's question...

remembering the metallurgy lectures i got when i looked 25 years younger and 25 kg lighter...

i am not the designer of the crankshaft but i believe that our crankshafts are made of soft and flexible steel alloy, surrounded by a hardened surface. to harden a steel surface you implement carbon atoms into the crystalstructure of the metal. these carbon atoms usually don't go very deep into the alloy, so corrosion and pitting could easaly eat in deeper then the hardened surface actually is. that could (most likely) affect everything including strength, fatique life and corrosion resistance. all these parameters, carefully engineered by the manufacturer, are kinda important when it comes to crankshafts of aircraft engines.

grinding/sanding away these spots will most likely not improve anything.

another thing with pitting is that it will never get better. if you reuse the crankshaft it could become much worse in a matter of minutes/hours.

long story short: this crankshaft has to see some really knowledgable expert on the topic before any further use. your local AP will usually not be sufficient enough to make a solid judgement.

but that's all my very personal opinion only.

We need a metallurgist to comment and ultimately amp up the willies you just cast upon me from my college past. Your summary sounds correct for case hardening but I remember it being deeper, in the hundredths, 50 thou-ish (material dependent of course). Nitriding can be a low as a few ten thousandths, also depending on material.

Anyone with material process knowledge of the cranks, your expert comments here would be appreciated.

F'ing great forum, isn't it?

Last edited:

This Engine has been sitting a long while, for those concerned with this condition on your own cranks. I played the long sitting engine lottery and seemed to have not won the grand prize.

I need to measure the thrust surface to case and oil slinger to case to see if there is any machining room, thrust face to gear seat will be hard to measure accurately without proper equipment.

I need to measure the thrust surface to case and oil slinger to case to see if there is any machining room, thrust face to gear seat will be hard to measure accurately without proper equipment.

Greg Dillon

Active Member

I had a similar issue on an automotive engine. I had the crank grinding shop weld up the thrust face and regrind to new spec. This may be an option for you.

Welding is a no no !

No Aircraft crankshaft should ever be welded. It’s specifically not allowed on certified crankshafts. I’ve heard of Airboat guys doing some welding on cranks with mixed results. The thrust face is a nitride hardened portion of the crankshaft and my understanding is welded areas don’t take to nitride hardening.

No Aircraft crankshaft should ever be welded. It’s specifically not allowed on certified crankshafts. I’ve heard of Airboat guys doing some welding on cranks with mixed results. The thrust face is a nitride hardened portion of the crankshaft and my understanding is welded areas don’t take to nitride hardening.

@Freeasm: the deepness of the carbon (or any other) atoms really depend on the hardening process the manufacturer found to be most suitable for this application. we don't know, but lycoming or lyclone makers or maybe guys like mike bush are able to judge that.

@jslow: i would hate to throw such an expensive part away. but maybe it's not all that bad. my point was that you really should ask experts on the topic before making any decision. just shoot an email to Mike from savvy aviation or so. they should at least know somebody you could ask. you will probably not find an final answer here.

remember, this is not your random attach bracket or something where one can get away with sandpaper or a welding machine. it's the crankshaft after all.

@jslow: i would hate to throw such an expensive part away. but maybe it's not all that bad. my point was that you really should ask experts on the topic before making any decision. just shoot an email to Mike from savvy aviation or so. they should at least know somebody you could ask. you will probably not find an final answer here.

remember, this is not your random attach bracket or something where one can get away with sandpaper or a welding machine. it's the crankshaft after all.

Internet opinions are interesting, but the most complete answer will come from a place like Aircraft Specialties (http://www.aircraftspecialties.aero/), the folks in Tulsa that overhaul and certify cranks. I’m guessing that with that picture, they can give you a definitive answer pretty quickly.

Paul

Paul

Expert Opinion

+1 Like I said in the first post AEA of Dallas (Aircraft Engines & Accessory Co). Both do excellent work but I’ve found AEA a little more down home. Paul is a gentleman and goes out of his way to make things right. (I’ve sent over 30 crankshafts to both companies) Just my opinion of course.

Duff

Internet opinions are interesting, but the most complete answer will come from a place like Aircraft Specialties (http://www.aircraftspecialties.aero/), the folks in Tulsa that overhaul and certify cranks. I’m guessing that with that picture, they can give you a definitive answer pretty quickly.

Paul

+1 Like I said in the first post AEA of Dallas (Aircraft Engines & Accessory Co). Both do excellent work but I’ve found AEA a little more down home. Paul is a gentleman and goes out of his way to make things right. (I’ve sent over 30 crankshafts to both companies) Just my opinion of course.

Duff

terrykohler

Well Known Member

Don’t Give Up Too Easily

What Paul said- you might have to send it to Aircraft Specialities or Lycoming. They’re likely to examine it, determine it’s a non-cleanup issue from machining a rough,as-forged surface, and not pitting corrosion. If there’s enough machine stock to keep it in limits, they’ll machine the surface(s) down then do some non-destructive testing and recertify it.

It’s worth a try.

Terry, CFI (and metallurgist)

What Paul said- you might have to send it to Aircraft Specialities or Lycoming. They’re likely to examine it, determine it’s a non-cleanup issue from machining a rough,as-forged surface, and not pitting corrosion. If there’s enough machine stock to keep it in limits, they’ll machine the surface(s) down then do some non-destructive testing and recertify it.

It’s worth a try.

Terry, CFI (and metallurgist)

Just a general comment when it comes to corrosion pits. They typically have a very high geometric Kt associated with them. Whether the pit will cause a crack to initiate depends on the stress levels, spectrum, material, material treatment etc. Even what looks like a shallow pit can be a big deal if it’s in the wrong place.

Over the years I’ve analyzed many, many parts for repairs where cracks had initiated at a corrosion pit. Sometimes the pit was so small that it was only obvious in a micrograph. Corrosion pits are very common initiation sites and not to be taken casually, especially in important monolithic machined parts.

The manufacturer can hopefully provide guidance on how much material removal is allowable.

Ren

(Durability and Damage Tolerance engineer)

Over the years I’ve analyzed many, many parts for repairs where cracks had initiated at a corrosion pit. Sometimes the pit was so small that it was only obvious in a micrograph. Corrosion pits are very common initiation sites and not to be taken casually, especially in important monolithic machined parts.

The manufacturer can hopefully provide guidance on how much material removal is allowable.

Ren

(Durability and Damage Tolerance engineer)

Last edited: