You might need torque/tightening for crush gaskets and NAS bolts for spar, they are a little higher than standard AN. The Lycoming sheet is also for standard engine hardware.

Pull test for crimped wires is also one you might want to have on hand. You won't test much but a battery cable terminal could require 500 lbs , so just knowing that might open you eyes to types of crimpers for those terminals.

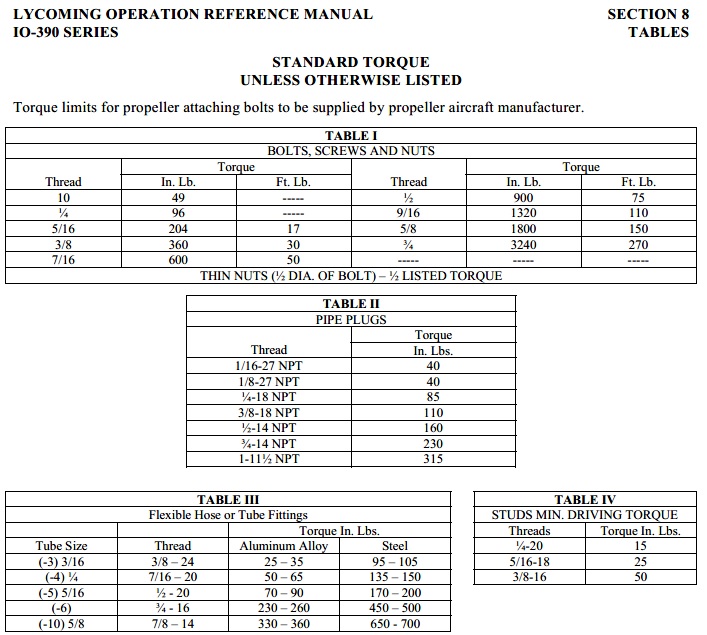

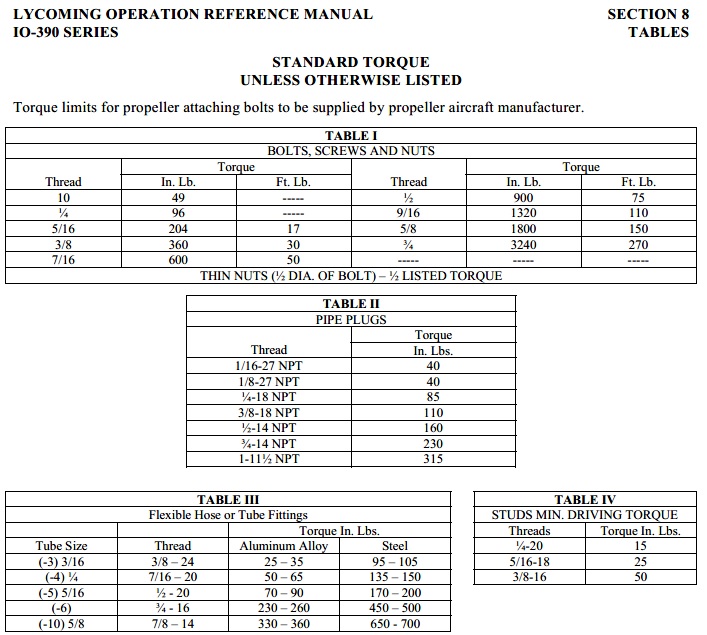

Engine fasteners are always torqued lubricated, and airframe "dry". Engine torques are for holding things tight, airframe 99% are for shear loading. Tight is more important for precise torque. Stretch, or bolt loading is more accurately represented by torque when performed with lubrication.

Surely there is something I am forgetting, but others will add.

An assortment of torque tools is in order. For screws I use a FAT wrench, a low cost torque screwdriver. Good for lots of small fasteners. A 0-60 in-lb beam, 20-100 in lb - 10-100 ft-lb and 10-150 ft lb. for consideration. Depending on location click type, beam, dial, or electronic. I fear the cost per fastener for electronics as I have a perfectly serviceable MAC click type that is 50 yrs old and still accurate (although I just repaired/cleaned it from operator error). CDI makes good torque wrenches, available many places.

Tools are a time saver, and sometimes a personal choice. Have fun with learning and building.