bullojm1

Well Known Member

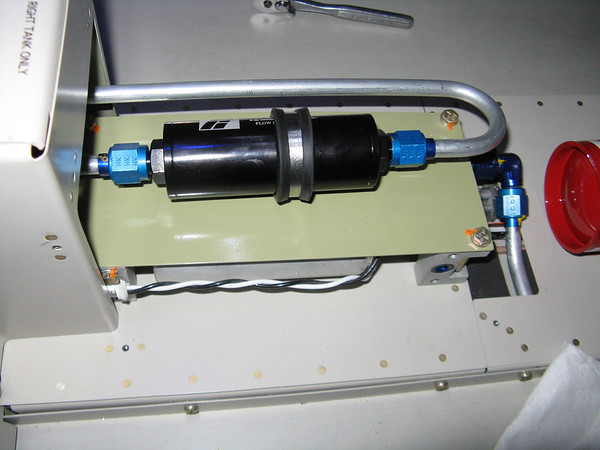

About a year ago I switched out my Airflow Performance fuel pump for the Fly EFII pump due to some low fuel pressure readings I would occasionally get on my IO-360. I elected to use their FF-2 90 micron pre-filter as it was much smaller than the AFP filter, and I sort of liked the idea of just buying a new one every year. It was a great upgrade - the Fly EFII pump was much quieter than the AFP pump.

During my annual this year, I came to the checklist item of "Clean and inspect the fuel filter". Well, this should be easy, I can just order a new filter on ACS or from Fly EFII. Well, $45 for a new filter + shipping seemed a little high, especially for a filter I know they sourced from somewhere else. So I pursued my favorite game of figuring out who makes a part someone else brands for their own and buy it off of Ebay or locally to save a buck or two.

It was a lot more difficult of a task than I thought it would be! It took a good hour, but I isolated the filter to being a Baldwin BF7519 / NAPA Gold 3269 / Donaldson P550446. NAPA had them in stock locally for $45, and Ebay had it for $22 shipped. Cool, I just saved enough to buy a nice (small) steak dinner.

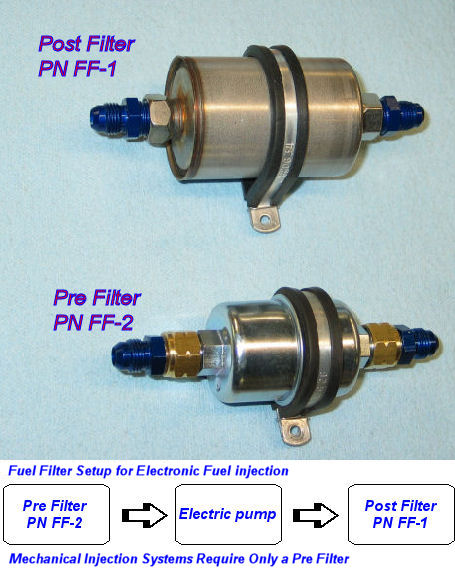

Fly EFII Image of the filter (lower, FF-2 Pre-filter)

A picture of the Baldwin BF7519

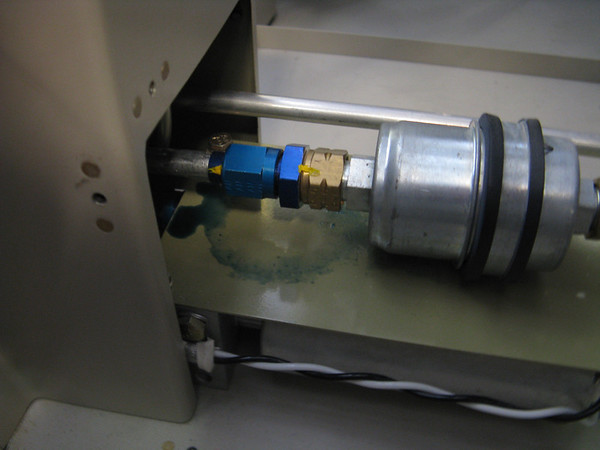

The one thing that bothered me was I couldn't figure out how the EFII fittings worked to adapt this filter to an AN6 fitting. The first thing I noticed was what appeared to be a compression fitting on the ends of the filter. Sure enough, that is what they used:

I was sort of shocked. I know it does not experience any pressure as it is on the intake side of the fuel pump, but I would expect something a little higher quality in the fuel system other than a compression fitting.

When I took the compression fitting off of the filter housing, some of the rubber grommet had deteriorated and left some small pieces of rubber inside the filter connector. Now, I don't see this as a safety issue, as the only time the rubber could erode like this is when the connector is removed. But still, not what I would expect in an aircraft fuel system.

Knowing the part number, I wanted to know what the filter micron level was. It was advertised as 90, but the only reference I could find was 149/150! (https://www.michelecaroli.com/info.php?oempartnumber=BF7519&donaldson=P550446, https://www.finditparts.com/products/2525254/wix-filters-33269). I could be wrong here, two references to the same filter both agree.

There's just too much here that I don't feel comfortable with to keep using this filter. I am planning to switch to the AndAir FX375-MK serviceable filter now.

During my annual this year, I came to the checklist item of "Clean and inspect the fuel filter". Well, this should be easy, I can just order a new filter on ACS or from Fly EFII. Well, $45 for a new filter + shipping seemed a little high, especially for a filter I know they sourced from somewhere else. So I pursued my favorite game of figuring out who makes a part someone else brands for their own and buy it off of Ebay or locally to save a buck or two.

It was a lot more difficult of a task than I thought it would be! It took a good hour, but I isolated the filter to being a Baldwin BF7519 / NAPA Gold 3269 / Donaldson P550446. NAPA had them in stock locally for $45, and Ebay had it for $22 shipped. Cool, I just saved enough to buy a nice (small) steak dinner.

Fly EFII Image of the filter (lower, FF-2 Pre-filter)

A picture of the Baldwin BF7519

The one thing that bothered me was I couldn't figure out how the EFII fittings worked to adapt this filter to an AN6 fitting. The first thing I noticed was what appeared to be a compression fitting on the ends of the filter. Sure enough, that is what they used:

I was sort of shocked. I know it does not experience any pressure as it is on the intake side of the fuel pump, but I would expect something a little higher quality in the fuel system other than a compression fitting.

When I took the compression fitting off of the filter housing, some of the rubber grommet had deteriorated and left some small pieces of rubber inside the filter connector. Now, I don't see this as a safety issue, as the only time the rubber could erode like this is when the connector is removed. But still, not what I would expect in an aircraft fuel system.

Knowing the part number, I wanted to know what the filter micron level was. It was advertised as 90, but the only reference I could find was 149/150! (https://www.michelecaroli.com/info.php?oempartnumber=BF7519&donaldson=P550446, https://www.finditparts.com/products/2525254/wix-filters-33269). I could be wrong here, two references to the same filter both agree.

There's just too much here that I don't feel comfortable with to keep using this filter. I am planning to switch to the AndAir FX375-MK serviceable filter now.