For the first time in my build I am regretting building the 9 instead of the 14. I had to get away from the plane before I ripped the canopy frame off and ran over it with the car. I thought I had it fitting pretty well then I cracked the tube on the frame. I had that welded then it still didn't fit right any more. I was carefully bending it to try to get it to fit and the other side started cracking. Motherf#$@^&!!

I read on Bruce Swayzes excellent build site that he riveted the sub panel structure to the plane so there would be no possible movement of anything that could screw up the canopy. So I just did that. I had a great riveting day when all the rivets came out perfect even the hard to reach ones. That doesn't happen too often. Didn't have to drill any out. I was HAPPY.

With much trepidation I just tried to fit the canopy frame. It fits worse than it ever has. I don't know at what point it stopped fitting well or what caused it. I was hoping it was the crack, but that was repaired and that still didn't help. It's as if the holes I drilled for the pivot points are wrong now.

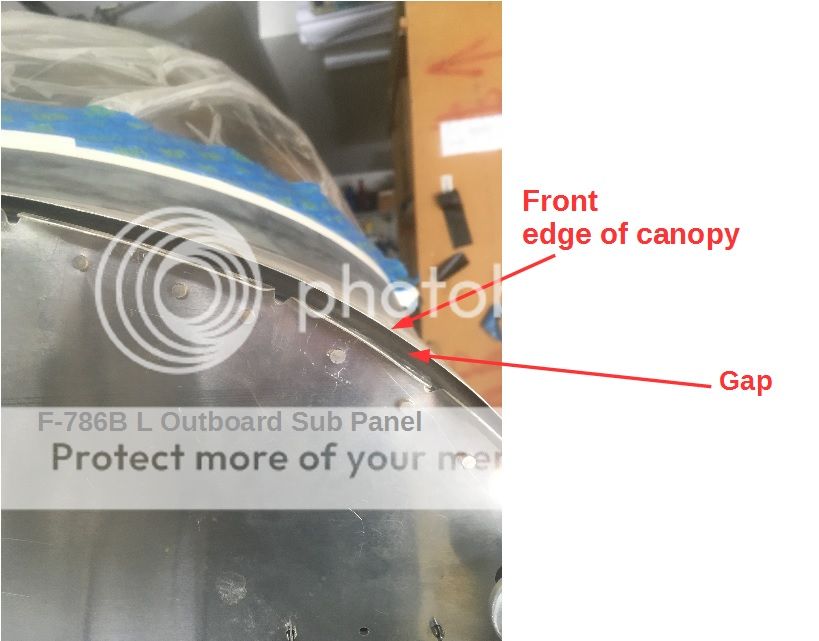

The only thing I can think to do is see if the welder can fill the pivot holes and push the canopy into a relatively decent fitting place and redrill the holes. Does that sound feasible? In the pics attached you can see the gap on the right side and the huge amount the frame sits above the front skin on the left side. It was never that high at the front like that. Anybody have any ideas???

[/IMG]

[/IMG]

[/IMG]

[/IMG]

I read on Bruce Swayzes excellent build site that he riveted the sub panel structure to the plane so there would be no possible movement of anything that could screw up the canopy. So I just did that. I had a great riveting day when all the rivets came out perfect even the hard to reach ones. That doesn't happen too often. Didn't have to drill any out. I was HAPPY.

With much trepidation I just tried to fit the canopy frame. It fits worse than it ever has. I don't know at what point it stopped fitting well or what caused it. I was hoping it was the crack, but that was repaired and that still didn't help. It's as if the holes I drilled for the pivot points are wrong now.

The only thing I can think to do is see if the welder can fill the pivot holes and push the canopy into a relatively decent fitting place and redrill the holes. Does that sound feasible? In the pics attached you can see the gap on the right side and the huge amount the frame sits above the front skin on the left side. It was never that high at the front like that. Anybody have any ideas???