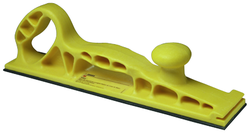

Dan would say the green 3m long board 40-80 grit lasts pretty well, I would agree. But, I switched to Permagrit for making a lot of plenums.

Pricey for a few uses but unbeatable for a lot of edges.

BTW - I use the dremel with HF diamond blades for well cured glass, for green glass a more coarse wheel is required.

If I built another plane, permagrit (or that style) countersinks would be purchased.

To the lower fairing, Vans has us put the attachment strip under the bottom rivets. I sanded the inside of the fairing to get the thickness even then added a spacer to avoid sanding the fairing to fit. Some outside (gel coat) sanding was done as the gel coat has no strength anyway. This way it was butted even along the length. The attach strip may have to be bent as the (my) fairing was not square. A lot of little fitting.

I saw one builder that split the fairing so the aft section could slide off (taildragger) and reach the electrical. I might try that on the next one too.