PaulvS

Well Known Member

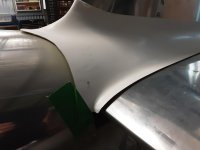

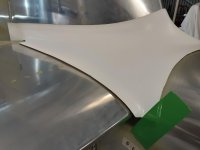

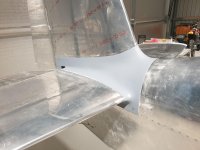

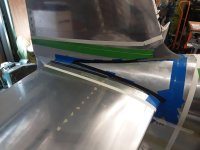

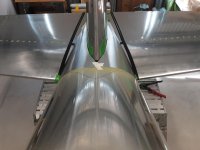

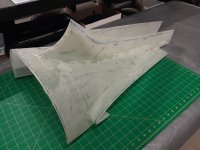

The fibreglass intersection fairing F-694B for the empennage on my -6A project does not appear to fit at all well, at least initially, and the gelcoat is rough. There are old posts on this problematic part and what other builders previously did but unfortunately many of the pictures have become lost.

I'm wondering what is the best plan of attack and whether to buy a new and hopefully better F-694B-1 fairing from Vans, or try to fix the existing part, or to make a new part from scratch?

I haven't done any fiberglass work for a while (built a sailing dinghy in my teens) and assume that fixing the current part would mean removing the gel coat and then cutting it up some and making various lap joint extensions around the edges before smoothing with micro. This could well be as much work as making a new part, I guess.

I would like it to end up looking like the fairing in this thread:

https://vansairforce.net/community/showthread.php?t=22931

Thanks for any suggestions.

Paul

I'm wondering what is the best plan of attack and whether to buy a new and hopefully better F-694B-1 fairing from Vans, or try to fix the existing part, or to make a new part from scratch?

I haven't done any fiberglass work for a while (built a sailing dinghy in my teens) and assume that fixing the current part would mean removing the gel coat and then cutting it up some and making various lap joint extensions around the edges before smoothing with micro. This could well be as much work as making a new part, I guess.

I would like it to end up looking like the fairing in this thread:

https://vansairforce.net/community/showthread.php?t=22931

Thanks for any suggestions.

Paul

Attachments

Last edited: