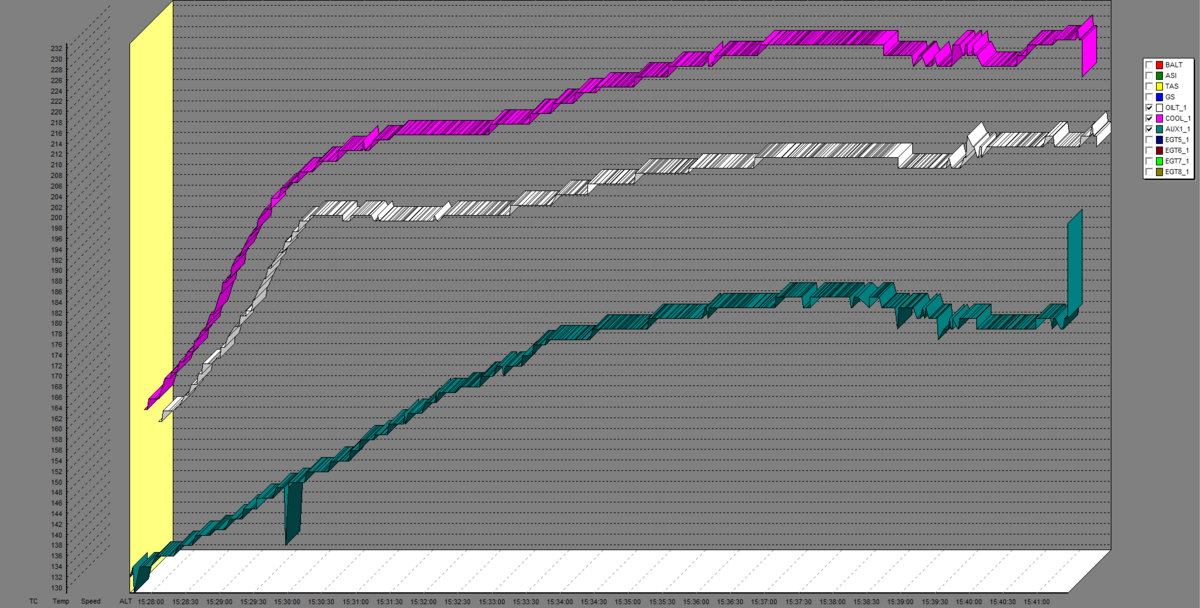

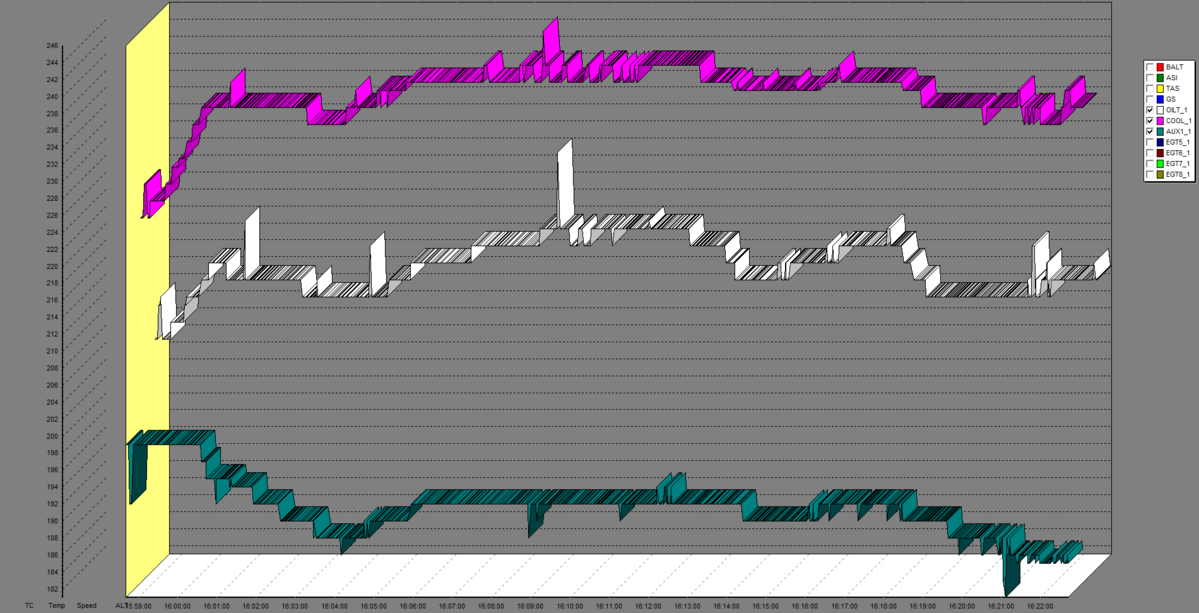

I monitor the oil temps in three spots. The sump, the cooler output and the filter adaptor. I see oil temps in the sump run ~ 230 to ~ 245f. Temps at the cooler output run ~ 185f and temps at the filter adaptor run ~ 180 to ~ 220f depending of flight and OAT.

Randy, any chance your sump sensor (installed in a tapped hole the oil screen cap?) is seeing some radiant heat from the exhaust? Your sump numbers look high.

There's a theory that the sensor length could have an effect on the oil temp reading, reading closer to the sump oil temp and less at the cooler return temp which are close to each other in the adaptor.

I suspect it's true. The two flows are assumed to mix before the sensor, but under some conditions I suspect they remain separated or only partially mixed until entering the filter.

.