RedRaider94

Active Member

Hoping someone might have an idea as this is driving me absolutely crazy.

RV7 - 1547 hours

Superior IO360

Slick mag

Light speed II EI

Silverhawk Bendix EX FI

Constant Speed prop

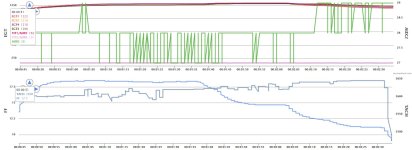

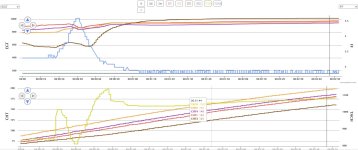

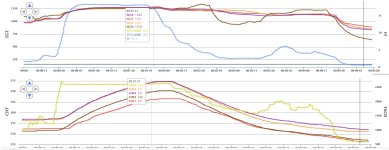

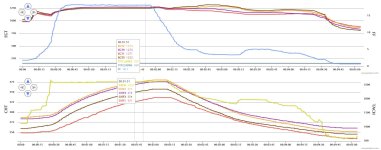

Problem: when doing touch and goes, the second takeoff and beyond sometimes has a feeling off power loss for a second or two then comes back and then a loss again, and then comes back. This is during climb out at max throttle.

*** it does not happen on the first takeoff of the day ***

The couple second feeling would be light switching off the Lightspeed and running just on the mag.

Fuel flow is in the 18 gph range when the issue is happening (that is normal fuel flow for me at takeoff) and RPM’s don’t go down while this happens - they stay steady.

The engine is not stopping, it’s just a slight loss of power for a second or two, comes back for a second or two, then loss again and so on.

This doesn’t happen on the first takeoff of the day and I am just stumped. Any initial ideas or how in the world would you go about troubleshooting something like this?

Thanks in advance for any thoughts!!

RV7 - 1547 hours

Superior IO360

Slick mag

Light speed II EI

Silverhawk Bendix EX FI

Constant Speed prop

Problem: when doing touch and goes, the second takeoff and beyond sometimes has a feeling off power loss for a second or two then comes back and then a loss again, and then comes back. This is during climb out at max throttle.

*** it does not happen on the first takeoff of the day ***

The couple second feeling would be light switching off the Lightspeed and running just on the mag.

Fuel flow is in the 18 gph range when the issue is happening (that is normal fuel flow for me at takeoff) and RPM’s don’t go down while this happens - they stay steady.

The engine is not stopping, it’s just a slight loss of power for a second or two, comes back for a second or two, then loss again and so on.

This doesn’t happen on the first takeoff of the day and I am just stumped. Any initial ideas or how in the world would you go about troubleshooting something like this?

Thanks in advance for any thoughts!!