Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Muffler and Exhaust pipes Coating

- Thread starter jsenft

- Start date

Paris12Man

Well Known Member

Coating

I had them coated with a ceramic coating by Cradin Industries Inc. They are located in Boerne, TX (www.cradin.com)

I believe they help the heat issue to some degree. While flying to Oshkosh in 2012 with two other RV12s, their oil temps were in the mid 230 degrees and mine was 209 degrees.

It took about a 10 days to ship and then to get them back. The invoice says they were coated with CI-528 if that helps.

Steve

I had them coated with a ceramic coating by Cradin Industries Inc. They are located in Boerne, TX (www.cradin.com)

I believe they help the heat issue to some degree. While flying to Oshkosh in 2012 with two other RV12s, their oil temps were in the mid 230 degrees and mine was 209 degrees.

It took about a 10 days to ship and then to get them back. The invoice says they were coated with CI-528 if that helps.

Steve

flyingriki

Well Known Member

http://www.vettermanexhaust.com/

Can I wrap my exhaust with automotive type of wrap material and obtain more power?

Any material on the exhaust will shorten it's life and failure will occur. We are using air cooled engines and one the best heat sinks on the engine is the exhaust system. The mass air flow comes in and is forced down and around the cooling fins and then is directed over the exhaust system and then exited out the bottom. If the exhaust is covered it cannot aid in the cooling process. Our tests show that any type of wrap on the exhaust makes both the cylinder head and exhaust temperature run higher. The stainless steel used (type 321) will degrade if the surface temperature is over 1250 degrees F. We also did not find a power increase of any kind by wrapping the exhaust.

How about ceramic coatings?

The jury is still out on them as to whether there is any benefit, however as stated above, they have the same effect as wrapping the exhaust. We do know that once a ceramic coating is applied, the system can never be repaired as it gets into the pores and welding is not possible. How about cooler cowl temperatures with either of the above? Yes, the temperature in the cowl will probably be cooler, but the engine produces so many BTU's of heat so it either is kept cool by the mass air flow or it stays in the cylinder heads.

Can I wrap my exhaust with automotive type of wrap material and obtain more power?

Any material on the exhaust will shorten it's life and failure will occur. We are using air cooled engines and one the best heat sinks on the engine is the exhaust system. The mass air flow comes in and is forced down and around the cooling fins and then is directed over the exhaust system and then exited out the bottom. If the exhaust is covered it cannot aid in the cooling process. Our tests show that any type of wrap on the exhaust makes both the cylinder head and exhaust temperature run higher. The stainless steel used (type 321) will degrade if the surface temperature is over 1250 degrees F. We also did not find a power increase of any kind by wrapping the exhaust.

How about ceramic coatings?

The jury is still out on them as to whether there is any benefit, however as stated above, they have the same effect as wrapping the exhaust. We do know that once a ceramic coating is applied, the system can never be repaired as it gets into the pores and welding is not possible. How about cooler cowl temperatures with either of the above? Yes, the temperature in the cowl will probably be cooler, but the engine produces so many BTU's of heat so it either is kept cool by the mass air flow or it stays in the cylinder heads.

I had my muffler assembly coated by Cradin also. I was chasing a possible vapor-lock problem at the time. Ironically the outfit was just ten minutes from my home. They use this coating in all kinds of industrial applications including the inside of some engines. Turn-around was inside of a week.

I wish I could provide some definitive data but I didn't start multi-probe temperature measurements in-cowl until after the muffler coating. I do not see the high oil temps observed early-on during those climbs to 10k doing the test cards. Of course the engine is presumably a little less tight now but it does get a little sultry here in the summer...

If high oil temps had been my issue, I would have first tried something like Jetguy's cowl-reduction surgery.

Jim

RV-12 #264

245 hours

I wish I could provide some definitive data but I didn't start multi-probe temperature measurements in-cowl until after the muffler coating. I do not see the high oil temps observed early-on during those climbs to 10k doing the test cards. Of course the engine is presumably a little less tight now but it does get a little sultry here in the summer...

If high oil temps had been my issue, I would have first tried something like Jetguy's cowl-reduction surgery.

Jim

RV-12 #264

245 hours

Jetguy

Well Known Member

Header Wrap update.

I had hot oil temps during the summer months. I tried header wrap on the to front headers and the muffler drum. I don't think it helped my high oil temp problem. My header wrap has been on for about a year. This winter I modified my cowl and moved my oil cooler forward 1 inch. I think this has helped but won't know until this summer around July when I will know for sure. Today I removed the header wrap and as you can see in the below pics that the wrap as stated by vetterman is has cause it to start rusting. With header wrap on you exhaust you can expect to cut the life of your exhaust in half. A few facts on my setup.

Live in a dry climate.

Have flown in light rain on occasion.

Did not install header tape wet.

Tape was on 1 year and about 100 hours.

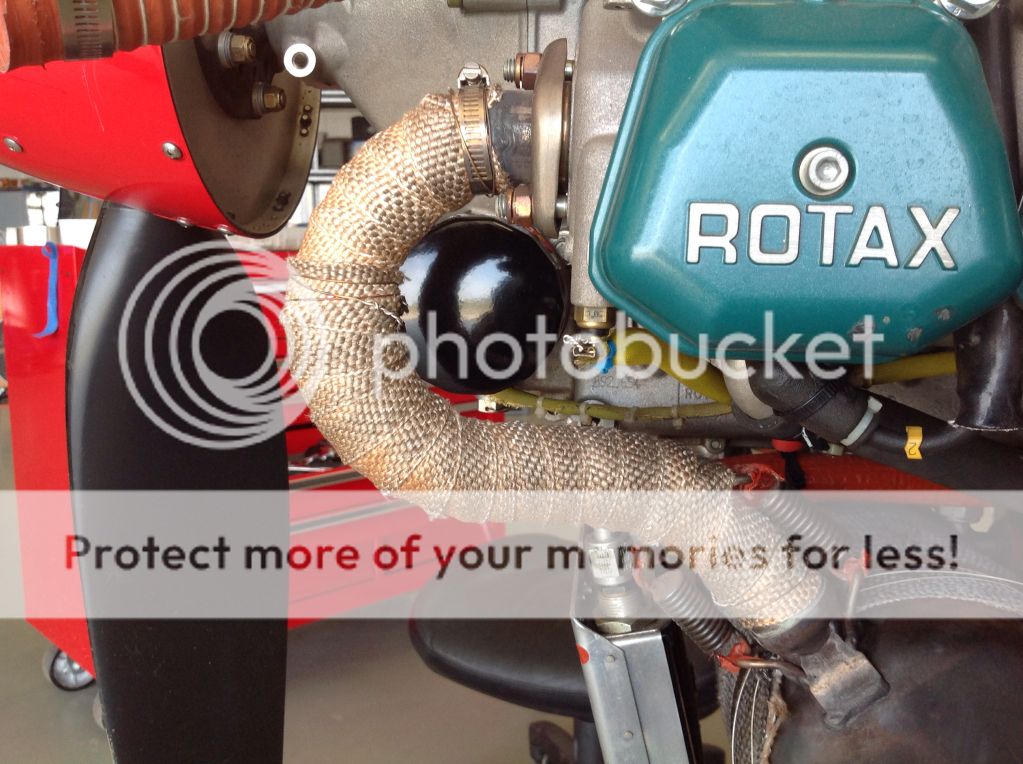

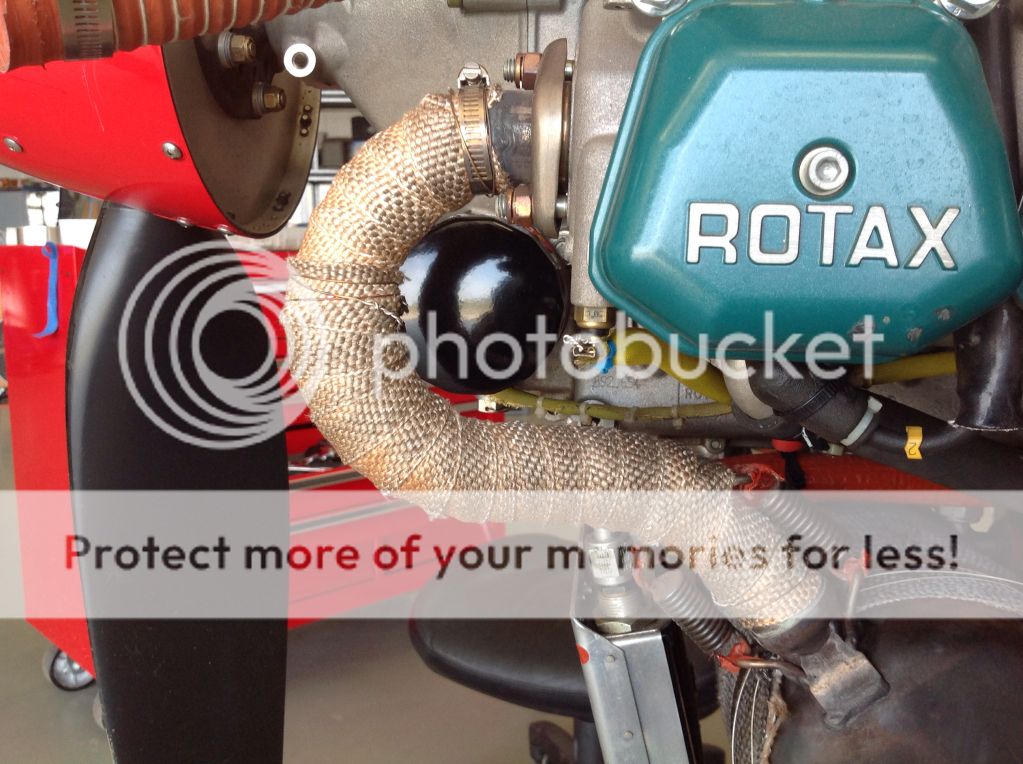

First pic wrap installed.

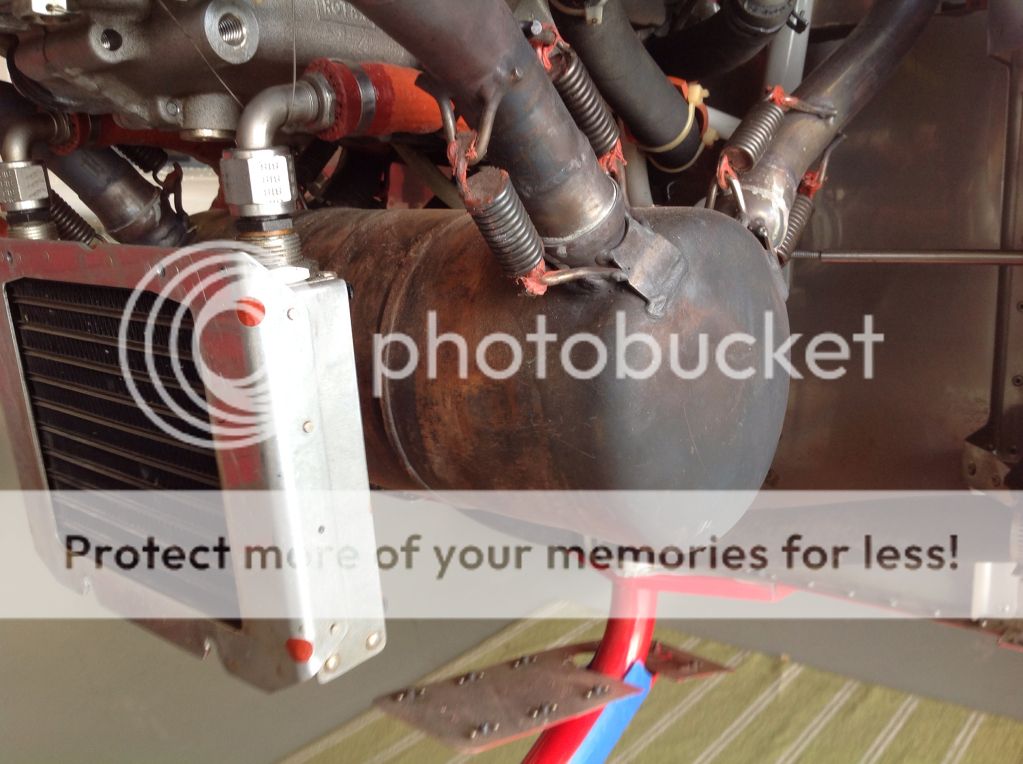

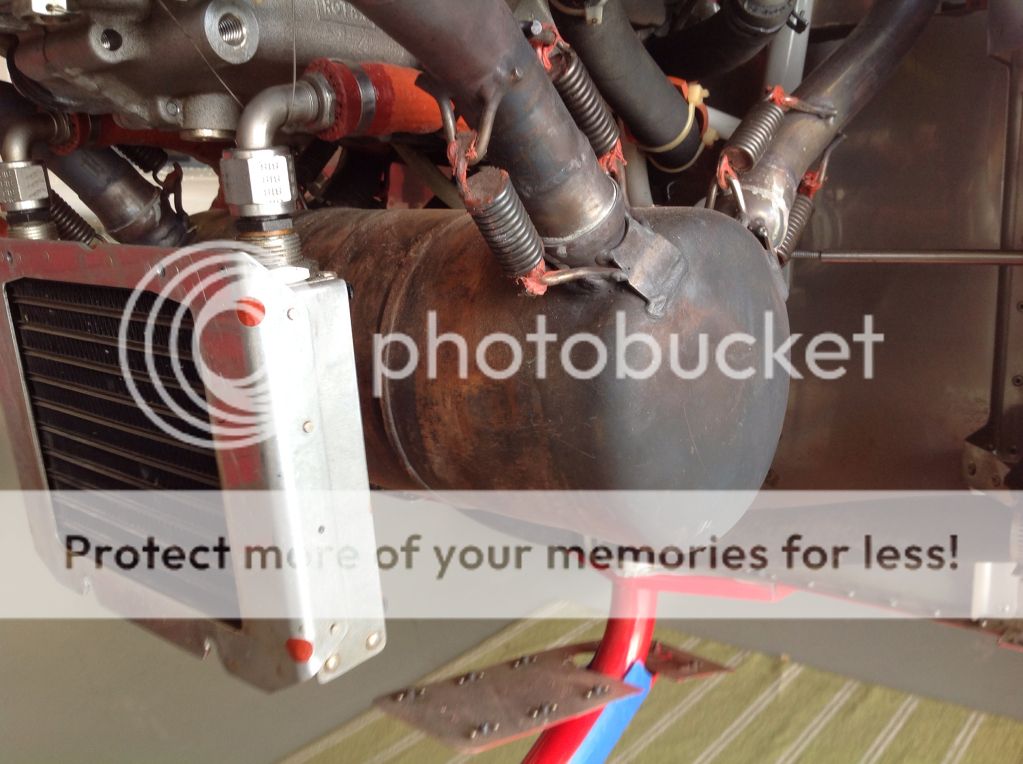

This pic after header wrap removed.

Pic of muffler after wrap removed.

So in the end you can see that the wrap promotes rust. Which would shorten the life of your exhaust system, by how much I don't know. Humid climates maybe worse in this respect. You make the call.

I had hot oil temps during the summer months. I tried header wrap on the to front headers and the muffler drum. I don't think it helped my high oil temp problem. My header wrap has been on for about a year. This winter I modified my cowl and moved my oil cooler forward 1 inch. I think this has helped but won't know until this summer around July when I will know for sure. Today I removed the header wrap and as you can see in the below pics that the wrap as stated by vetterman is has cause it to start rusting. With header wrap on you exhaust you can expect to cut the life of your exhaust in half. A few facts on my setup.

Live in a dry climate.

Have flown in light rain on occasion.

Did not install header tape wet.

Tape was on 1 year and about 100 hours.

First pic wrap installed.

This pic after header wrap removed.

Pic of muffler after wrap removed.

So in the end you can see that the wrap promotes rust. Which would shorten the life of your exhaust system, by how much I don't know. Humid climates maybe worse in this respect. You make the call.

BillL

Well Known Member

I have been hearing about high temps, and JetGuy just said it was oil temps. From his pictures it appears the large, hot surface area of that muffler is in full view to the backside of the oil cooler. The cooler would get a huge radiant energy input due to the view factor. If oil cooling is the issue, as anyone put a simple heat shield over the full face of the muffler? It can be thin aluminum and with a small gap (3/16-1/4")to the muffler. If it works, then stainless may be better in the long run.

Is oil temperature the issue and has the shield been tried?

Is oil temperature the issue and has the shield been tried?

Jetguy

Well Known Member

A heat shield has been tried by different people within the RV12 community with varied results. Some builders have reported less than 3/4 of an inch between the rear of the oil cooler and the drum muffler. Durning the summer months depending on your location in the USA. OAT could reach over 100F. That muffler in these conditions would be over 1200F. Oil temps could reach over 250F durning long climbs to cool air at altitude.

266F is the red line.

232F to 265F is the yellow arc.

121F to 231F is the green arc.

(+-2 degree error)

You can operate in the yellow arc as much as you feel comfortable,

You make the call

266F is the red line.

232F to 265F is the yellow arc.

121F to 231F is the green arc.

(+-2 degree error)

You can operate in the yellow arc as much as you feel comfortable,

You make the call

John, my prediction is your time in the yellow is over. You might see it on steep climb out, but for the most part you will be in the green.

Bill, Larry Geiger built a heat shield and I don't recall his results, but I am pretty sure he removed it.

Regarding the wrap, Larry Baker tried it in an effort to reduce oil temps prior to moving the oil cooler. IT did not help at all, in fact, due to the wrapping of the springs, he wound up with a massive exhaust leak in flight.

Bill, Larry Geiger built a heat shield and I don't recall his results, but I am pretty sure he removed it.

Regarding the wrap, Larry Baker tried it in an effort to reduce oil temps prior to moving the oil cooler. IT did not help at all, in fact, due to the wrapping of the springs, he wound up with a massive exhaust leak in flight.

Bill_H

Well Known Member

Wrapping or a shield feeds a vicious circle. Either reduces the space behind the cooler for the air to exit having come through the cooler. That offsets the benefit of the wrap or shield. Moving the cooler forward and increasing the gap between it and the muffler seems the best solution.

Moving the cooler forward and increasing the gap between it and the muffler seems the best solution.

To my knowledge, it has helped all who have moved it.

John, what do you have your temp. sensor wires covered with?

Geico266

Well Known Member

John, my prediction is your time in the yellow is over. You might see it on steep climb out, but for the most part you will be in the green.

Bill, Larry Geiger built a heat shield and I don't recall his results, but I am pretty sure he removed it.

Regarding the wrap, Larry Baker tried it in an effort to reduce oil temps prior to moving the oil cooler. IT did not help at all, in fact, due to the wrapping of the springs, he wound up with a massive exhaust leak in flight.

The heat shield seem to help some, but it wasn't a huge amount. Maybe 5 degrees. I think moving the oil cooler forward is the way to go. The radiant heat from the muffler is an issue for sure.

Maybe a second oil cooler?

Geico266

Well Known Member

Wrapping or a shield feeds a vicious circle. Either reduces the space behind the cooler for the air to exit having come through the cooler. That offsets the benefit of the wrap or shield. Moving the cooler forward and increasing the gap between it and the muffler seems the best solution.

I believe Bill is correct. The heat shield simply was too close to the radiator to allow the same air flow without it.

Jetguy

Well Known Member

Here's your answer Dave.John, what do you have your temp. sensor wires covered with?

Mr. Gasket 6326Y - Mr. Gasket Thermal Sleeving For Electrical Wire.

Link: http://www.jegs.com/i/Mr-Gasket/720/6326Y/10002/-1?parentProductId=#moreDetails

Good to 1200F, 1/4"ID.

Those wires are really small, about the size of old style telephone wire. Thinking long term and about the Texas summer heat I thought this would help reduce wear and tear on those little wires over the next 20 years.