Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SB-00023 published: RV-12/12iS Engine Mount Standoff Inspection/Replacement

- Thread starter greghughespdx

- Start date

LettersFromFlyoverCountry

Well Known Member

tried to order not available til 1/12/2021

Alan

RV12- getting ready to hang engine

Odd. I ordered yesterday too and didn't see that message. Were you able to order and they just said it was on backorder? Or were they not taking the order at all?

B

LettersFromFlyoverCountry

Well Known Member

I didn't mention it but, amongst all the other work done last year, I also serviced the carbs and had the mags overhauled.

I cannot believe Vans is out of stock on the very day they announced the replacement part, claiming they had stuff in stock. Surely these should have been prioritised to folk with flying aircraft. I'm not happy having to wait best part of two months :-(

I don't suppose anyone has ordered one from stock which they don't need for two months?

Cheers...Keith

To clarify, the service bulletin was posted almost two weeks ago.

NinerBikes

Well Known Member

I thought Rotax 912 ULS's have electronic ignition, not magnetos?

gblwy

Well Known Member

I thought Rotax 912 ULS's have electronic ignition, not magnetos?

Sorry, old duffers term of phrase. The little black boxes on top of the engine went away and came back after emptying my wallet.

gblwy

Well Known Member

To clarify, the service bulletin was posted almost two weeks ago.

Mmm, that explains things. I only got an email notification on Tuesday.

DaleB

Well Known Member

Around 650 hours on our RV-12, and last night we found a crack on the right side exactly where the SB diagram showed. There doesn't appear to be a crack on the left, but to be honest once I saw the one on the right I didn't look too closely elsewhere. The crack we found covers about 120 degrees or maybe more, around the top of the tube.

Sure wish we had a way to heat that hangar. It's going to be bloody cold in January.

Sure wish we had a way to heat that hangar. It's going to be bloody cold in January.

NinerBikes

Well Known Member

Around 250 hours on mine, did the oil and filter, no cracks noted in locations shown.

Around 650 hours on our RV-12, and last night we found a crack on the right side exactly where the SB diagram showed. There doesn't appear to be a crack on the left, but to be honest once I saw the one on the right I didn't look too closely elsewhere. The crack we found covers about 120 degrees or maybe more, around the top of the tube.

Sure wish we had a way to heat that hangar. It's going to be bloody cold in January.

Can you post a picture of the crack with the weld intersection in the frame.

Does anyone have a Service Bulletin log built already to track these? The list is getting longer and it seems like a good list to keep track of ones status on as parts delivery is delayed or completing them at the next annual is to take place.

DaleB

Well Known Member

Can you post a picture of the crack with the weld intersection in the frame.

Eventually. At this point it seems I won’t have a real compelling reason to go to the hangar until late January or early February.

But... it’s right where the SB illustration shows it. Just a little hairline crack, but no challenge to spot at all.

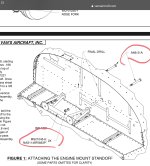

SB 00023

While I was doing the nose leg replacement a few weeks ago I checked my standoff and found a crack on the right side just as the pictures show. Easy to see when your looking for it, but would be hard to spot if Van’s hadn’t put the SB out! Was not to hard to do and not very many things to take apart as I first thought. Put new isolators in at the same time. 675 hours, not a trainer, prop balanced and carbs keep tuned.

While I was doing the nose leg replacement a few weeks ago I checked my standoff and found a crack on the right side just as the pictures show. Easy to see when your looking for it, but would be hard to spot if Van’s hadn’t put the SB out! Was not to hard to do and not very many things to take apart as I first thought. Put new isolators in at the same time. 675 hours, not a trainer, prop balanced and carbs keep tuned.

What’s different?

There are 3 posts asking what are the improvements/changes in the -1 new standoff/truss mount. I scrolled through the site looking for the new revisions from Scott or Greg but didn’t see one. Might have missed it.

Now that I’ve received my new truss part I don’t see a noted difference. It might be inside the assembly or an improved welding process? Curious more than than anything. Thanks

There are 3 posts asking what are the improvements/changes in the -1 new standoff/truss mount. I scrolled through the site looking for the new revisions from Scott or Greg but didn’t see one. Might have missed it.

Now that I’ve received my new truss part I don’t see a noted difference. It might be inside the assembly or an improved welding process? Curious more than than anything. Thanks

The following from Van's support line: "Visually the parts should look very much the same, the difference is the wall thickness of the cross tube has been increased form .049 up to .083, almost double."

There are 3 posts asking what are the improvements/changes in the -1 new standoff/truss mount. I scrolled through the site looking for the new revisions from Scott or Greg but didn’t see one. Might have missed it.

Now that I’ve received my new truss part I don’t see a noted difference. It might be inside the assembly or an improved welding process? Curious more than than anything. Thanks

There are 3 posts asking what are the improvements/changes in the -1 new standoff/truss mount. I scrolled through the site looking for the new revisions from Scott or Greg but didn’t see one. Might have missed it.

Patrick- Don't have the time at the moment to locate the post you want, but it was posted that the tubing on the new engine mount is made from tubing that has a much thicker wall dimension than the original engine mount.

gblwy

Well Known Member

No hoist needed

Just an observation. I replaced mine without using an engine hoist. I just needed someone to provide a little lift from the front of the engine to take the weight off the top bolts while I removed and reinserted them.

Not a difficult job, but it took two of us the best part of a short winter's day to removed the old unit, and the same again to install the new part.

Just an observation. I replaced mine without using an engine hoist. I just needed someone to provide a little lift from the front of the engine to take the weight off the top bolts while I removed and reinserted them.

Not a difficult job, but it took two of us the best part of a short winter's day to removed the old unit, and the same again to install the new part.

Now that I’ve received my new truss part I don’t see a noted difference. It might be inside the assembly or an improved welding process? Curious more than than anything. Thanks

Sorry that we missed replying on that here (I thought I had, actually). Yep, the wall thickness was substantially increased on the new part. Externally there is no real identifiable difference.

Just an observation. I replaced mine without using an engine hoist. I just needed someone to provide a little lift from the front of the engine to take the weight off the top bolts while I removed and reinserted them.

Not a difficult job, but it took two of us the best part of a short winter's day to removed the old unit, and the same again to install the new part.

Must be a fabulously devoted friend to stand there holding your engine for 2 days

For those interested, the most time consuming part of doing this job is gaining access to the aft side of the two bolts that penetrate the firewall (and that doesn't take all that long). After doing that, swapping the parts can easily be done in under an hr (if you safety wire the Adel clamps closed first....)

gblwy

Well Known Member

Two steps

As you may have noticed, I had to wait for a replacement part. In the interim I removed the old part (because I hoped - unsuccessfully - to get it welded as a temporary measure) and replaced it for the duration with two bits of threaded rod. Otherwise my friend would have had to hold the engine for two weeks!

I remembered the trick with the Adel clamps, so that wasn't an issue. It did take some time to remove the water hose which was in the way. And it takes forever with new tie-wraps to ensure that nothing will vibrate/rub or whatever.

Job done, Scottish weather has been amazing for the last few days, and we are now Covid-grounded :-(

As you may have noticed, I had to wait for a replacement part. In the interim I removed the old part (because I hoped - unsuccessfully - to get it welded as a temporary measure) and replaced it for the duration with two bits of threaded rod. Otherwise my friend would have had to hold the engine for two weeks!

I remembered the trick with the Adel clamps, so that wasn't an issue. It did take some time to remove the water hose which was in the way. And it takes forever with new tie-wraps to ensure that nothing will vibrate/rub or whatever.

Job done, Scottish weather has been amazing for the last few days, and we are now Covid-grounded :-(

I ordered my stand off in November. I've been at the point of being ready to hang the engine since December and was expecting it in January. Today I was told it would be mid March before I would receive it.(or later)

Should I go ahead and hang the engine now and replace this later or wait

Alan

N603NH reserved

Should I go ahead and hang the engine now and replace this later or wait

Alan

N603NH reserved

I ordered my stand off in November. I've been at the point of being ready to hang the engine since December and was expecting it in January. Today I was told it would be mid March before I would receive it.(or later)

Should I go ahead and hang the engine now and replace this later or wait

Alan

N603NH reserved

Sorry about the additional delay Alan.

There should be no issue for you to just move ahead and install the engine so that you can continue progressing with your build. The part is easy to change with the engine installed as long as you have a means to support the front of the engine while you are doing it (a rope capable of holding 100 lbs, thrown over a rafter above the prop shaft would be more than sufficient).

DaleB

Well Known Member

I don't want to burden the staff at Van's with additional work and phone calls, but am I to understand there are further delays in shipping these parts? I ordered back in December and was told "probably late January". If it's going to be much later... well, in all honestly, I guess it means nothing, since we can't fly until it gets here, whenever that is. It would just be nice to know.

Harvey rv12

Well Known Member

engine standoff mount

Was told this morning from Vans the engine mount standoff weldment will not ship until mid March :-(. Mine has a visible crack. Bummer.

Was told this morning from Vans the engine mount standoff weldment will not ship until mid March :-(. Mine has a visible crack. Bummer.

I would call Van's. they are trying to get the parts out first to people that have cracks.

Alan

Yes, please do call if you have a crack and need a replacement. Our team is doing the best they can to prioritize based on that. I spoke with them yesterday about the couple folks who have posted here, but directly calling is the best way to make sure your needs are known, if you have a cracked standoff that we need to try to prioritize. Thanks!

Harvey rv12

Well Known Member

Great news

My engine mount was shipped from Vans today.

My engine mount was shipped from Vans today.

Harvey rv12

Well Known Member

Trick with adel clamps

Gblwy, can you or someone share the trick with the adel clamps?, is there some unique way of removing and reinstalling them?. I have fumbled with them before.

Thanks in advance

Gblwy, can you or someone share the trick with the adel clamps?, is there some unique way of removing and reinstalling them?. I have fumbled with them before.

Thanks in advance

Adel clamps

I did what others suggested, safety wired them together. If you have to, use a longer bolt.

I did what others suggested, safety wired them together. If you have to, use a longer bolt.

JwWright57

Well Known Member

They’re castellated nuts with Cotter Pins, no not an issue.

Castellated nuts? I don’t see that

Attachments

JwWright57

Well Known Member

Sorry Bob, but i just don’t see that. What plans page has that? This pic is the latest version i could find.See post #39. They’re Castellated on the iS mount.

Attachments

Sorry Bob, but i just don’t see that. What plans page has that? This pic is the latest version i could find.

See page 5 of the KAI that came with my Powerplant kit.

https://www.dropbox.com/s/q75bmihfb3iujsx/46iS Engine Install.pdf?dl=0

DaleB

Well Known Member

Mine (S/N 120222) uses castellated nuts and cotter pins. In one of the Skyview installation sections I found a picture of one of the factory planes that showed the same part attached the same way. I don't know when they made the change, but originally they used cotter pins.

JwWright57

Well Known Member

Thanks Bob. The engine kit I received around Christmas has locknuts and a revison for that page (8/19) .See page 5 of the KAI that came with my Powerplant kit.

https://www.dropbox.com/s/q75bmihfb3iujsx/46iS Engine Install.pdf?dl=0

Which is good lol since thats the hardware they sent me.

rcarsey

Well Known Member

Received mine May of ‘19. Maybe Scott can share what prompted the change?

I second that! Mine uses cotter pins. The only issue I had was that after torqueing, I couldn't install the cotter pin for 2 reasons.. the castellation didn't line up with the drilled hole (when does it ever!?), and also there was interference between the standoff and the cotter pin during insertion.

I had to make sure the bolt's drilled hole was up/down and not left/right. So maybe with locknuts, there's a better probability that builders will get the torque closer to spec.. ?

I second that! Mine uses cotter pins. The only issue I had was that after torqueing, I couldn't install the cotter pin for 2 reasons.. the castellation didn't line up with the drilled hole (when does it ever!?), and also there was interference between the standoff and the cotter pin during insertion.

I had to make sure the bolt's drilled hole was up/down and not left/right. So maybe with locknuts, there's a better probability that builders will get the torque closer to spec.. ?

Standard procedure for torquing castellated nuts is to first torque to minimum spec, then continue to tighten until the holes line up. This will keep you within the required torque range.

Received mine May of ‘19. Maybe Scott can share what prompted the change?

Ease of installation.

AN-310 and cotter pins has been the traditional method for these type of fasteners (large sized fasteners loaded in shear and tension), but there is now decades of service history of using just all steel self locking nuts. Many certificated aircraft are configured this way.

Many builders of other RV models have been flying for a long time with steel self locking nuts.

Other than ease of installation, I know of no other benefits one way or the other.

Limited supply of WD-01221-1

Got notice from Bruce at Vans that the first batch of new parts came in but there were not enough to satisfy my order due to orders ahead of me. I should get one from the next batch but do not know when that will happen.

Got notice from Bruce at Vans that the first batch of new parts came in but there were not enough to satisfy my order due to orders ahead of me. I should get one from the next batch but do not know when that will happen.

DaleB

Well Known Member

WOW.

We finally had temperatures and opportunity yesterday to pull the original WD-1221 out and put in the new one. I had seen one crack during the initial inspection per the SB, but when we got it out and had a closer look it was much worse than we imagined. The right side was cracked close to 3/4 around the tube, and there was also a crack on the left side that we had not seen. It probably would have been visible with a flashlight and inspection mirror, but after seeing the first crack I hadn't looked any further.

Both cracks were exactly where the diagram in the SB showed they would be. On careful consideration, we figured that even if the tube had broken completely the airplane would not have fallen from the sky... it looks like both sides would have stayed attached, but it's still a little unnerving to see cracks like that.

We finally had temperatures and opportunity yesterday to pull the original WD-1221 out and put in the new one. I had seen one crack during the initial inspection per the SB, but when we got it out and had a closer look it was much worse than we imagined. The right side was cracked close to 3/4 around the tube, and there was also a crack on the left side that we had not seen. It probably would have been visible with a flashlight and inspection mirror, but after seeing the first crack I hadn't looked any further.

Both cracks were exactly where the diagram in the SB showed they would be. On careful consideration, we figured that even if the tube had broken completely the airplane would not have fallen from the sky... it looks like both sides would have stayed attached, but it's still a little unnerving to see cracks like that.

RFSchaller

Well Known Member

Dale, what was the service life on the part. Hours? Type of flying?

DaleB

Well Known Member

Dale, what was the service life on the part. Hours? Type of flying?

A little under 600 hours currently. Three of us fly the plane, all low time pilots but nobody is abusing it. It's flown 99% off paved runways. I will say, though, that I've never been happy with the vibration level. We shipped the prop blades off to Sensenich last year for refurb and balance, when we had to replace the front half of the hub. It's better since then, but still not as good as I'd like it.

Right now we're finishing up replacing that tube, plus the trim servo and we're installing a landing light and the new throttle spring plates. I plan to re-balance the carbs again, then we're going to find a place to get the prop dynamically balanced. I don't think there is anyone around here that can do it, I'm considering a trip down to 52F to get it balanced.

RFSchaller

Well Known Member

These failures don’t seem to have a common root cause. All the more important to do the replacement suggested by the mother ship.

cactusman

Well Known Member

Vibration is an enemy of many things. The value of (at least one) good prop balance and carb synching should not be underestimated. I just dropped $4k on a Catto 3-blade based on some discussions i had. I'm hoping that will allow me to enjoy this airplane even more.

Last edited: