rocketman1988

Well Known Member

Great news!

We will no longer have to deal with an external flap position sensor on the RV-10!

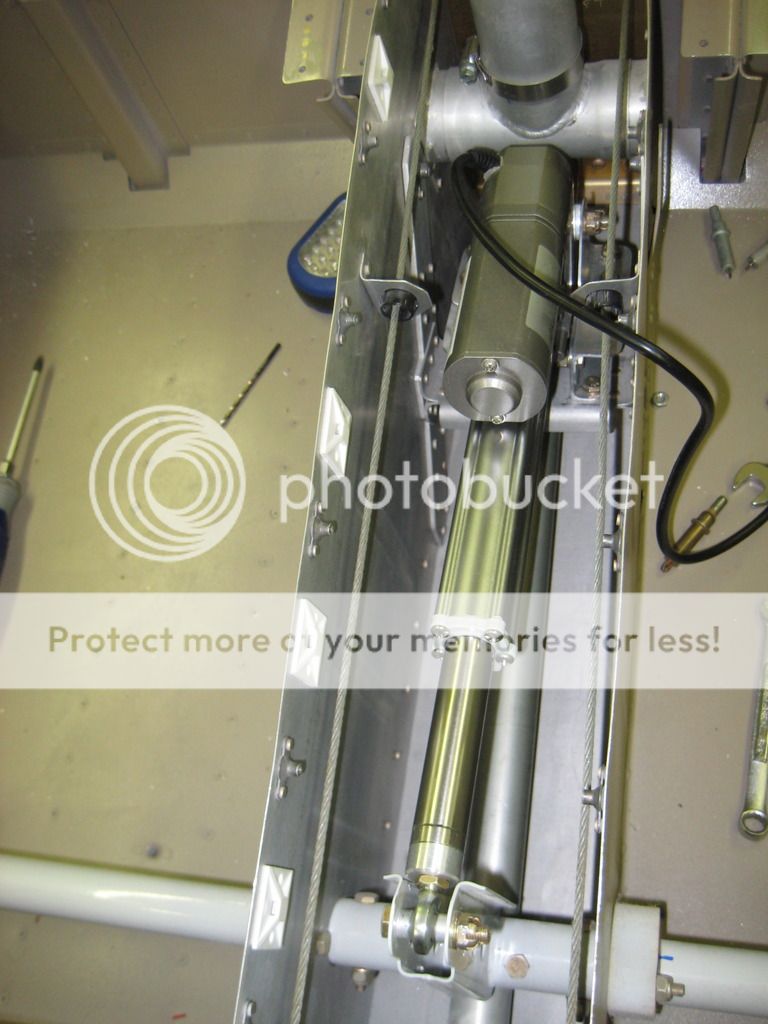

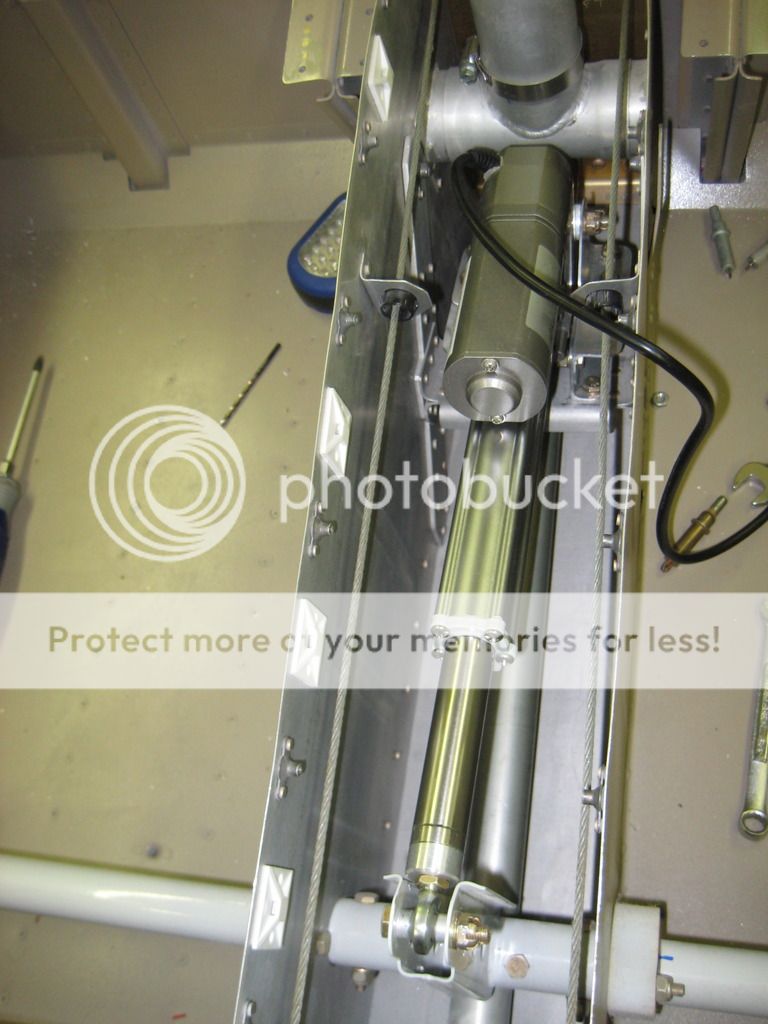

I just finished installing one of the prototype flap actuators from PHAviation.com. These actuators have a BUILT IN potentiometer for position information, so say goodbye to the external sensor mounts and linkages.

Here is a side by side comparison of the actuators:

The construction and finish of the new actuator is awesome!

It took me about a day to retrofit my RV-10 which is about 90% complete. The install process involved fabricating a mount that bolts to the original actuator mount. As the new actuator is longer, the new mount extends the pivot point 1 1/2 inches farther forward. The mount was fabricated from 1/16 x 1 1/2 x 1 1/2 and 1/16 x 1 x 1 angle, and was a fairly simple task.

Installation during initial construction would be a breeze!

I made a couple of 5/16 ID x 5/8 OD spacers that were 1/2" long for the actuator pivot. I opted to add a washer on each side to increase the clearance on the actuator housing, though this was probably not necessary.

Once the actuator was centered in the tunnel and the pivot point was located 1 1/2" forward of the original, the mounting flanges were match drilled to the support angles. All parts were then removed, demurred, and finished. Nut plates were installed and the actuator was installed.

I needed to extend the rod end bearing about 1/4" to provide clearance on the flap bell crank. I tested the operation and range of motion and it was perfect!

The actuator is quiet and VERY smooth in operation. It has three additional sensor wires (just like the external position sensor) that will connect to an indicator.

I am very impressed with this unit and the customer service received from Pat. This is a definite upgrade over the stock unit and simplifies the overall system.

Highly recommended!

Now all that is left to do is remove the external sensor!

For those that are interested in this upgrade, I would be happy to discuss it further!

We will no longer have to deal with an external flap position sensor on the RV-10!

I just finished installing one of the prototype flap actuators from PHAviation.com. These actuators have a BUILT IN potentiometer for position information, so say goodbye to the external sensor mounts and linkages.

Here is a side by side comparison of the actuators:

The construction and finish of the new actuator is awesome!

It took me about a day to retrofit my RV-10 which is about 90% complete. The install process involved fabricating a mount that bolts to the original actuator mount. As the new actuator is longer, the new mount extends the pivot point 1 1/2 inches farther forward. The mount was fabricated from 1/16 x 1 1/2 x 1 1/2 and 1/16 x 1 x 1 angle, and was a fairly simple task.

Installation during initial construction would be a breeze!

I made a couple of 5/16 ID x 5/8 OD spacers that were 1/2" long for the actuator pivot. I opted to add a washer on each side to increase the clearance on the actuator housing, though this was probably not necessary.

Once the actuator was centered in the tunnel and the pivot point was located 1 1/2" forward of the original, the mounting flanges were match drilled to the support angles. All parts were then removed, demurred, and finished. Nut plates were installed and the actuator was installed.

I needed to extend the rod end bearing about 1/4" to provide clearance on the flap bell crank. I tested the operation and range of motion and it was perfect!

The actuator is quiet and VERY smooth in operation. It has three additional sensor wires (just like the external position sensor) that will connect to an indicator.

I am very impressed with this unit and the customer service received from Pat. This is a definite upgrade over the stock unit and simplifies the overall system.

Highly recommended!

Now all that is left to do is remove the external sensor!

For those that are interested in this upgrade, I would be happy to discuss it further!