Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Service Bulletins 19-08-26 and 16-05-23 Published - Nose gear leg and fork

- Thread starter greghughespdx

- Start date

RFSchaller

Well Known Member

I am doing my annual now (ELSA). I decided to defer nose gear leg replacement to next year. I put a bore scope down the leg to examine it, but the results are not definitive. Maybe a professional NDE guy could draw conclusions, but the geometry of access and lack of a 45 deg mirror to look 90 deg off camera axis made it a fruitless task for me. I have about 950 hrs TTAF.

My plan is to section the area of interest when I replace it and PT it to see if anything bad was developing, so I?ll post agin on the thread next March.

My plan is to section the area of interest when I replace it and PT it to see if anything bad was developing, so I?ll post agin on the thread next March.

NinerBikes

Well Known Member

Nose gear, new wheel pant, and nose fork arrived, March 7th. Drill bits and a few other parts still on back order. If the stuff arrives in time, it gets installed before the annual, otherwise, there's next years annual.

E-LSA, 229 hrs.

Our Annual is due by March 31st, so Van's is trying hard to keep the annual guys in business with timeliness.

E-LSA, 229 hrs.

Our Annual is due by March 31st, so Van's is trying hard to keep the annual guys in business with timeliness.

Last edited:

I put a bore scope down the leg to examine it, but the results are not definitive. Maybe a professional NDE guy could draw conclusions, but the geometry of access and lack of a 45 deg mirror to look 90 deg off camera axis made it a fruitless task for me.

Just to make sure people are aware: Performing a borescope analysis of the inside of the tube is not considered by Van's to be an acceptable method of determining whether or not the material has yielded and/or the part has been compromised. If it was a valid means, we certainly would have recommended it rather than going through the process of changing and manufacturing the new parts. I'll explain.

The primary/initially affected area is not examinable, so if you saw something inside the tube, that actually would not be an indicator of initial-stage material yield/failure. Rather, it would indicate the part was already significantly compromised and had already progressed beyond the initial problem stage. Even a perfect-appearing tube inner surface does not indicate whether the part is ok or not. The initial material yield/failure/subsequent crack occurs on the outer surface/diameter of the tube, in the area on that outer tube surface that is unfortunately obscured by the adjoining parts and associated welds. In other words, the lack of a visible crack on the inside of the tube does not guarantee a healthy, unaffected part. It is possible to have a compromised part that does not yet show signs of cracking on that inner diameter surface.

In fact, on the subject airplane that was the focus of the investigation that led to this service bulletin, the material failure occurred in a way where there was never a visible crack on the inner surface of the tube. The crack had progressed partially through the tube thickness at that location but not all the way, but had progressed significantly circumferentially around the outer surface of the tube. The entire area of cracked material was located under the obscured area already noted above.

While a borescope analysis certainly is interesting, and can potentially show if a failure has progressed significantly and the tube is already very badly compromised, Van's must make sure we are clear on this point: Do not perform a borescope analysis of the tube as an alternate means of compliance - It simply is not an acceptable means.

Sorry to feel the need to be blunt/direct, but in the interest of clarity and ultimately safety, we must make sure everyone knows exactly what is considered acceptable per the engineers that have very carefully examined and analyzed the parts. While a borescope might be able to tell you if the part is already badly damaged and failure is probably already imminent, you cannot examine the part to determine with any reliability whether or not it is compromised.

Last edited:

pilotyoung

Well Known Member

Service Bulletins

Greg,

We all appreciate your honesty and detailed explanations on this forum. This thread has raised questions about Safety Directives and Alerts, Service Bulletins, and Notifications and Letters.

Will you explain the reason or cause for issuing a Safety Directive vs. a Service Bulletin vs. a Notification or Letter?

Thanks.

John

Greg,

We all appreciate your honesty and detailed explanations on this forum. This thread has raised questions about Safety Directives and Alerts, Service Bulletins, and Notifications and Letters.

Will you explain the reason or cause for issuing a Safety Directive vs. a Service Bulletin vs. a Notification or Letter?

Thanks.

John

RFSchaller

Well Known Member

Thanks, Greg. I was just posting a data point. In the end each EAB and ELSA owner has the responsibility for making decisions regarding these issues. I just decided this was best for me and wanted to let others making the decision aware of what I found. I agree any visible defect indicates failure, and I would not fly with it. My decision to operate another year is what is right for me not necessarily the right thing for anyone else.

Rich

Rich

Will you explain the reason or cause for issuing a Safety Directive vs. a Service Bulletin vs. a Notification or Letter?

John, that?s a great question, there is not a lot of info on this subject out there.

First, the definitions. This is out of AC65.32a. The FAA copied it verbatim from ASTM F2295 7.2.2.1 through 7.2.2.3.

z. Safety Directive ASTM Designation F2483. A directive issued by a manufacturer of a special LSA intended to correct an existing unsafe condition. Compliance with safety directives is addressed in 14 CFR part 91, ? 91.327 and the recording is required in ? 91.417. Safety directives are addressed in applicable consensus standards which include provisions for maintaining the continued airworthiness of an aircraft and correcting safety-of-flight issues. Safety directives are considered mandatory on SLSA.

(1) Safety Alert. For notifications that require immediate action, see ASTM F2295.

(2) Service Bulletin (SB). For notifications that do not require immediate action but do recommend future action, see ASTM F2295.

(3) Notification. For notifications that do not necessarily recommend future action but are primarily for promulgation of continued airworthiness information, see ASTM F2295.

You need a copy of the ASTM standards to understand the mechanics of what determines a Safety Directive. This material is copyrighted so I can?t post a copy or provide a link, but I will try to explain.

ASTM F2295 uses a formula to calculate the ?Safety Risk Factor? by using weighted values (between -1 & +4) to the following;

1) Safety Effect (Catastrophic to Minor)

2) Operational Use (hire or personal)

3) Percent of use by Population (% of fleet for hire)

4) Number of Occurrences

5) Events vs. Population

6) Time between events

The ?Safety Risk Factor? is the product first three lines added to the sum of last three line. It will have a value between 2 and 40.

We plug this into the F2295 Risk Assessment Evaluation Chart. The Y axis is? Safety Effect? (0= minor, 4= Catastrophic,) and the X axis is ?Safety Risk Factor? (0 ? 50.) The chart has 3 diagonal bands, the bottom left band (from 0,0) is ?General Aviation Alert,? The middle band is ?Potential Safety of Flight Bulletin,? and the top right band (to 50,4) is ?Urgent Safety of Flight Situation.?

Simply locate a point on the chart using the ?Safety Effect? value and the calculated ?Safety Risk Factor? and see what band the event falls into.

Some of this may have changed. As of October 3, 2019 the FAA retired F2295 and replace it F3198-18. F2295 only applied to Airplanes and Gliders. Gyros, WS, PP and Balloons each had their own Specification for ?Continued Airworthiness,? each containing unique definitions for ?Safety Alert,? ?Service Bulletin? and ?Notification.? The new specification F3198-18 crosscuts and is common to all Light Sport classes.

Greg,

We all appreciate your honesty and detailed explanations on this forum. This thread has raised questions about Safety Directives and Alerts, Service Bulletins, and Notifications and Letters.

Will you explain the reason or cause for issuing a Safety Directive vs. a Service Bulletin vs. a Notification or Letter?

Thanks.

John

MMilller covered the standards pretty well in his reply. The standards he mentioned significantly define the risk assessment process we follow, which is the primary and key component of our decision process. From our web site, in the Service Information section, we classify the different documents we publish (which are listed here in descending order of risk severity/priority) as follows:

SAFETY DIRECTIVES AND ALERTS

For all ELSA or SLSA aircraft, these documents represent critical safety of flight notifications that require immediate action before further flight. Safety Directives and Safety Alerts are mandatory and may be enforced by the FAA. Note that for EAB aircraft, similar-level published information may be included under the ?Service Bulletins? category of documents.

SERVICE BULLETINS

Service Bulletins typically do not mandate immediate action from a regulatory perspective but do strongly recommend future action. Timeframes and methods to comply may vary and are described in each document. These are items that represent an important or critical need and should be reviewed and complied with per the contents of each document in the specified timeframe. Van?s Aircraft strongly encourages all owners and operators to comply with the information in these documents.

NOTIFICATIONS AND LETTERS

Notifications/Letters do not necessarily recommend future action but are primarily for the promulgation of continued airworthiness information. These documents explain or notify owners of service- or configuration-related information pertaining to their aircraft. It is important to review these notifications and letters when they are published.

REVISIONS AND CHANGES

This section includes revisions to Van?s Aircraft documentation, such as Builder Plans/Kit Assembly Instructions and other aircraft documents, and includes explanations of what?s changed in each revision where appropriate. Note that we do not typically post documentation updates that consist of minor changes such as spelling and minor error corrections, etc. Rather, updates are published here when material changes occur.

For all ELSA or SLSA aircraft, these documents represent critical safety of flight notifications that require immediate action before further flight. Safety Directives and Safety Alerts are mandatory and may be enforced by the FAA. Note that for EAB aircraft, similar-level published information may be included under the ?Service Bulletins? category of documents.

SERVICE BULLETINS

Service Bulletins typically do not mandate immediate action from a regulatory perspective but do strongly recommend future action. Timeframes and methods to comply may vary and are described in each document. These are items that represent an important or critical need and should be reviewed and complied with per the contents of each document in the specified timeframe. Van?s Aircraft strongly encourages all owners and operators to comply with the information in these documents.

NOTIFICATIONS AND LETTERS

Notifications/Letters do not necessarily recommend future action but are primarily for the promulgation of continued airworthiness information. These documents explain or notify owners of service- or configuration-related information pertaining to their aircraft. It is important to review these notifications and letters when they are published.

REVISIONS AND CHANGES

This section includes revisions to Van?s Aircraft documentation, such as Builder Plans/Kit Assembly Instructions and other aircraft documents, and includes explanations of what?s changed in each revision where appropriate. Note that we do not typically post documentation updates that consist of minor changes such as spelling and minor error corrections, etc. Rather, updates are published here when material changes occur.

The risk assessment formula (we are operating under the new 3198-18 standard by the way), which results in the Safety Risk Factor calculation is used to objectively calculate the risk associated with the specific situation being assessed. We can always "bump up" the risk/severity if there is a reason to do so. This provides a standardized method of risk scoring that is generally accepted by the industry and any applicable regulatory agencies, while also allowing us room to act in a more conservative manner than the risk score dictates, if and when we to determine it is necessary to do so.

In addition, a vendor of a component (for example a Rotax engine) may issue a safety directive or service bulletin. We then issue a similar document at or above the level of risk specified by the component vendor, if applicable to our aircraft.

Hope that helps!

greg

pilotyoung

Well Known Member

Service Bulletins

Greg and MMiller,

Thanks for your replies. It helps me understand your reasoning for deciding which one to use.

John

Greg and MMiller,

Thanks for your replies. It helps me understand your reasoning for deciding which one to use.

John

found my answer in engine mounting section. Carry on

Last edited:

skydiverlv

Well Known Member

I am finished with the nose gear installation and have the 18" bits and guide bushings for sale listed in the classifieds.

Included are the 3 bits, 2 guide bushings and the length of PEX tubing that makes the process much easier.

The bushings and PEX are the same diameter and I found that taping the two end to end with gorilla tape was of much benefit. After taping you can easily insert the guide bushing into the existing 3/8" hole of the mount inside the tunnel then drill through the PEX and bushing.

Included are the 3 bits, 2 guide bushings and the length of PEX tubing that makes the process much easier.

The bushings and PEX are the same diameter and I found that taping the two end to end with gorilla tape was of much benefit. After taping you can easily insert the guide bushing into the existing 3/8" hole of the mount inside the tunnel then drill through the PEX and bushing.

skydiverlv

Well Known Member

I performed the gear leg replacement solo and found no need for another set of hands.

DHeal

Well Known Member

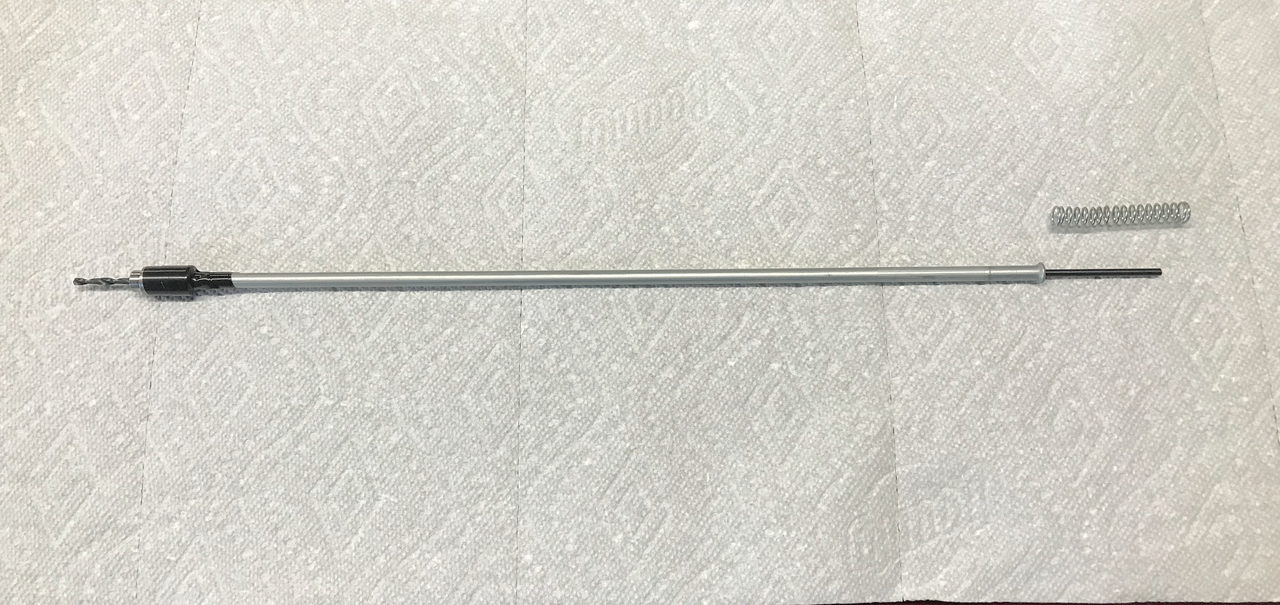

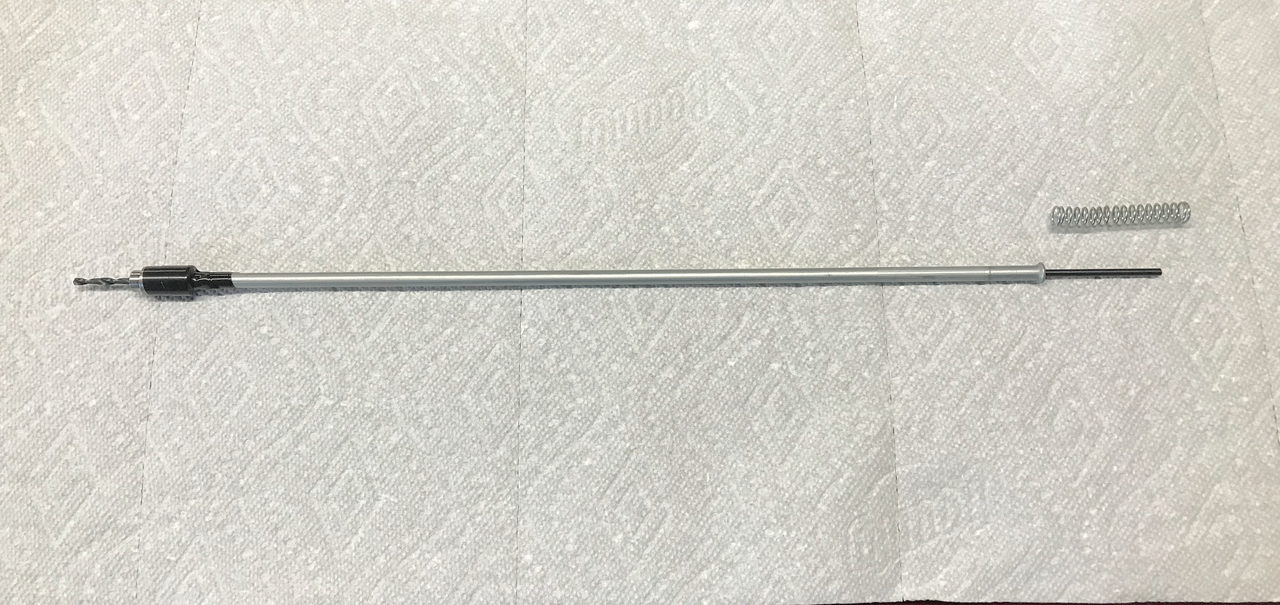

Here is another tip for SB 19-08-026 compliers: I took note of some earlier commentors' useful suggestions to use a tube or spring to keep the drill bushing in position while drilling the two lower strut/motor mount holes. I took an @ 14 5/8" long piece of @ 5/16" ID tube (plastic, rubber, or metal) and taped one end of the tube to the appropriate drill bushing. Insert the appropriate drill bit through the tube and bushing, then place a small thrust washer, an @ 1 1/4" long moderate-force compression spring, and then another small thrust washer (add a bit of grease on the washers) at the end of the tube. Tighten this "assemblage" in the drill chuck so that the tip of the drill bit falls just shy of end of the bushing (think "frightened turtle"). It is then a very easy job to sit in the cockpit, index the bushing into the existing 3/8' firewall hole, line up the drill, hold the tube to keep it from spinning, and push the drill motor to drill the holes -- the "assemblage" places pressure on the bushing and helps to keep it properly aligned while the drill bit does it's work (don't forget to use some drill bit lubricant such as Boelube, etc.). Easy-peasy!

RFSchaller

Well Known Member

Greg,

Your post says Safety Directives are mandatory for SLSA and ELSA. My understanding of the FAA position is that ELSA are just like any other experimental aircraft and have no mandatory service bulletins, ADs, SDs etc. what is the regulation you base your statement on?

Rich

Your post says Safety Directives are mandatory for SLSA and ELSA. My understanding of the FAA position is that ELSA are just like any other experimental aircraft and have no mandatory service bulletins, ADs, SDs etc. what is the regulation you base your statement on?

Rich

To hold the guide I used a wrap of blue painters tape around the guide and partly up the drill bit. Start with the brill bit point just peeking out of the guide.

The 1/8 - 18" drill bit I got from Vans wasn't too sharp, I made it through the left hole but was only able to mark the right side with it. I removed the strut and finished drilling on the bench all the way to 3/8".

The 1/8 - 18" drill bit I got from Vans wasn't too sharp, I made it through the left hole but was only able to mark the right side with it. I removed the strut and finished drilling on the bench all the way to 3/8".

Piper J3

Well Known Member

I?m getting ready to install my new nose gear and wondering why the lower engine mount holes need to configured at assembly. The flange for the lower engine mount has four holes that I assume are clearance for existing rivets. If clearance holes for rivets can be pre-drilled by Van?s it seems the lower engine mount holes could be also. Maybe lower engine mount holes aren?t a ?known? location?

I must be missing something?.

I must be missing something?.

I must be missing something?.

The production process of the RV-12 nose gear assembly includes heat treating after the welding is completed.

When heat treating is done on welded 4130 steel assemblies they can (and do) change shape slightly from what the were when welding in the welding fixture.

To try and minimize this, they are bolted to a very heavy fixture while they go through heat treat to try and stabilize any movement but it doesn't resolve it 100%.

Because of this movement, no two gear legs are exactly the same, which is a problem when you are wanting a very close tolerance fit of fasteners, and have to remove one to install a different one.

This is not a problem on a new build because you just match drill the holes based on the nose gear leg once you bolt it in place and all is good.

It does induce a problem if you need to retrofit a different nose gear to a fuselage that has mounting holes already drilled in the firewall.

That is why there is two different version of the nose gear available, and why it was advantageous for anyone that was in the process of working on the finish kit, to wait for the new nose gear leg. This gave them the option of just bolting it in place and match drilling from the front.

Piper J3

Well Known Member

That might explain why my nose strut is slightly off-centerline with the fuselage. Perhaps it warped during heat treating...

As part of my preflight inspection the last thing I do before climbing aboard is to walk about 40? behind the airplane and eyeball the center axis of the fuselage. I line up the vertical fin and tail tiedown hook with the front nose strut. I look for symmetry of the entire airplane as well as straightness of antennas hanging off the bottom. That?s how I notice my nose strut is not centered.

Somebody asked me why I do this and I suspect it?s a carryover from flying model airplanes. Usually before launching a model airplane you hold it at arm?s length and look for warped wing or asymmetrical flight surfaces.

As part of my preflight inspection the last thing I do before climbing aboard is to walk about 40? behind the airplane and eyeball the center axis of the fuselage. I line up the vertical fin and tail tiedown hook with the front nose strut. I look for symmetry of the entire airplane as well as straightness of antennas hanging off the bottom. That?s how I notice my nose strut is not centered.

Somebody asked me why I do this and I suspect it?s a carryover from flying model airplanes. Usually before launching a model airplane you hold it at arm?s length and look for warped wing or asymmetrical flight surfaces.

That might explain why my nose strut is slightly off-centerline with the fuselage. Perhaps it warped during heat treating...

Are you talking about your old nose wheel strut or your new nose wheel strut?

Piper J3

Well Known Member

Are you talking about your old nose wheel strut or your new nose wheel strut?

My bad... Old one. I'm just starting process to install new strut.

Piper J3

Well Known Member

I?m installing new front gear leg without any assistance due to COVID social distancing. So far, I have about 10 hours into the job. I?m following the SB and using the DHeal post #170 tip for spring pressure to position drill bushing. Works a charm?

I found it extremely difficult to drill the first holes. 1/8?x18? long high speed drill hardly touched the heat-treated plate on the gear leg. So, what I did was use 1/8? drill with bushing to spot the location on the plate. I then removed the gear and drilled the holes on a bench. I ended up using a center drill to pick up the spotted location and start the first hole through the plate. Holes were bumped up to 3/8? and deburred before reinstallation.

DHeal Spring Method to Position Drill Bushing

Drill Bushing Taped to Outer Sleeve

Compression Spring w/ Thrust Washers

Center Drill for Starting Hole in Solid Material

Ready to Install

I found it extremely difficult to drill the first holes. 1/8?x18? long high speed drill hardly touched the heat-treated plate on the gear leg. So, what I did was use 1/8? drill with bushing to spot the location on the plate. I then removed the gear and drilled the holes on a bench. I ended up using a center drill to pick up the spotted location and start the first hole through the plate. Holes were bumped up to 3/8? and deburred before reinstallation.

DHeal Spring Method to Position Drill Bushing

Drill Bushing Taped to Outer Sleeve

Compression Spring w/ Thrust Washers

Center Drill for Starting Hole in Solid Material

Ready to Install

DHeal

Well Known Member

Yes, drilling the initial 1/8" dia hole can be a bit challenging but frankly I had no big issue with it. For me, applying pressure on the 1/8" bit while stabilizing the long thin drill bit shaft was the challenge -- the long outer tube helps to stabilize the thin wobbling 1/8" bit shaft. Drilling of the subsequent 1/4" and 3/8" bits was easy to do in place -- use lubricant, pressure, and slow drill speed.

ps -- Installation of the two large Adel clamps holding the lower coolant hose may also prove to be a challenge. I used all of my Adel clamp installation tricks (e.g., safety wire ties, small needle-nosed Vice Grip pliers, awl, etc.) to line up and secure those two clamps.

ps -- Installation of the two large Adel clamps holding the lower coolant hose may also prove to be a challenge. I used all of my Adel clamp installation tricks (e.g., safety wire ties, small needle-nosed Vice Grip pliers, awl, etc.) to line up and secure those two clamps.

Last edited:

Piper J3

Well Known Member

DHealInstallation of the two large Adel clamps holding the lower coolant hose may also prove to be a challenge. I used all of my Adel clamp installation tricks (e.g. said:I used safety wire twisted tightly on each clamp. Use an alignment pin thru the holes when you tighten safety wire and holes will remain aligned. Having each clamp safety wired closed makes this an easy job, otherwise it's like fighting a mouse trap.

Piper J3

Well Known Member

I decided to remove the tiedown / trailer winch hook on the front of the nose strut while completing the SB for the new nose gear. I fly off of a grass strip and the nose fairing gets full of bugs and grass clippings. The winch hook and clearance slot in the strut fairing are difficult to keep clean. I?m in the process of filling in the fairing slot with fiberglass. I might even run just the bare strut ? looks a bit like a 7A.

rv3flier

Well Known Member

I just finished the installation of my new nose gear and had just drilled the nose gear to install the nose gear fairing. Unfortunately, while taping the first hole for #8-32 the tap broke just as the tap was cutting the first thread or so. There's nothing to grab on to to try to remove it. I'm looking for suggestions as to how to proceed.

TIA John

TIA John

rv3flier

Well Known Member

Strangely enough, this is the first tap I've ever broken -- thanks for the suggestions. I'm going to try a small needle nose pliar first and, if that doesn't work, 40 mile round trip to get a tap extractor --- then if all else fails the punch and enlarge to a #10 option.

rv3flier

Well Known Member

So far, I haven't been lucky. When I went to buy another 8-32 tap, I discovered that the correct pilot hole drill is a #29 and not a #30 called out in the plans. I re-drilled the remaining hole with the #29 and the tap cut the threads easily. However, I still haven't managed to get the broken tap out. I've tried a Dremel with a tapered grind stone to create a dimple for the drill bit to center on, 3 different drill bits while barely making a dent in the tap. It also won't punch out. So, I'm going to see if a dentist might have an old diamond tipped bit I can try.

RFSchaller

Well Known Member

This is a Hail Mary, but can you get the tip of a punch between the tap flutes and try to hit the punch to get the tap to rotate CCW and back out?

NinerBikes

Well Known Member

I always dread putting the safety wire back on the Gascolator. Such a tight space.

Service the Gascolator during your Condition inspection when you have removed the old gear leg. Easy peasy

Swap out the screws for like socket head screws, and make sure to add Nordlock #10 washers under the socket heads... and the need for safety wire will be resolved.

RFSchaller

Well Known Member

I agree. One of the best suggestions I got from the blog was using socket head screws and Nordlock washers.

The aft most holes in the nose gear leg were not aligned with holes in the bottom

of the fuselage. I had to elongate the holes in order to get the screws in.

The alignment problem might be due to the heat treating process after the holes were punched or drilled.

The new gear leg kit comes with another cushion clamp for the coolant hose.

Use two cushion clamps instead of drilling a hole in the gear leg for one clamp.

of the fuselage. I had to elongate the holes in order to get the screws in.

The alignment problem might be due to the heat treating process after the holes were punched or drilled.

The new gear leg kit comes with another cushion clamp for the coolant hose.

Use two cushion clamps instead of drilling a hole in the gear leg for one clamp.

gblwy

Well Known Member

Nose leg failure

I know I'm late to the party, but I now have a broken noseleg, and subsequently a broken aeroplane.

My flying partner had a bounced landing, and the noseleg broke right off near the midpoint. There's no obvious indication that fairing screwholes in the leg had anything to do with it.

However, looking at the break it appears there may have been a pre-existing crack running in an arc around the circumference. I'm no expert, and the UK Air Accident Investigation Branch have requested material from either side of the break to undertake their own investigation. I cut off a slice either side of the break which they now have. I'll be interested in the outcome, bearing in mind the discussions above.

This was the original noseleg with 600 hours. I'm not aware of any previous hard landing which may have initiated a crack. At the annual inspection three months previous to the accident I removed the noseleg fairing to examine the leg, but didn't notice anything untoward.

Treat the noseleg with respect, especially if you are still awaiting an updated one! Everything forward of the step bulkhead is now scrap - including the step bulkhead itself unfortunately - so wiring, brake lines, rudder cables, and static line all have to come out prior to installing new parts.

I know I'm late to the party, but I now have a broken noseleg, and subsequently a broken aeroplane.

My flying partner had a bounced landing, and the noseleg broke right off near the midpoint. There's no obvious indication that fairing screwholes in the leg had anything to do with it.

However, looking at the break it appears there may have been a pre-existing crack running in an arc around the circumference. I'm no expert, and the UK Air Accident Investigation Branch have requested material from either side of the break to undertake their own investigation. I cut off a slice either side of the break which they now have. I'll be interested in the outcome, bearing in mind the discussions above.

This was the original noseleg with 600 hours. I'm not aware of any previous hard landing which may have initiated a crack. At the annual inspection three months previous to the accident I removed the noseleg fairing to examine the leg, but didn't notice anything untoward.

Treat the noseleg with respect, especially if you are still awaiting an updated one! Everything forward of the step bulkhead is now scrap - including the step bulkhead itself unfortunately - so wiring, brake lines, rudder cables, and static line all have to come out prior to installing new parts.

Last edited:

Piper J3

Well Known Member

Treat the noseleg with respect, especially if you are still awaiting an updated one! Everything forward of the step bulkhead is now scrap - including the step bulkhead itself unfortunately - so wiring, brake lines, rudder cables, and static line all have to come out prior to installing new parts.

Can you share a photo of the broken part?

gblwy

Well Known Member

Link to pic

Try this, I forget how to post pics. I suspect the brown patch (see top half of the first pic) may illustrate the extent of a possible crack. I think this was the bit that remained with the wheel. The lower part of the first pic is the bit attached to the firewall. It happened on a grass strip, so this lower shot may just be mud.

https://www.dropbox.com/s/ovo6t5p0soq9ys4/Noseleg.jpg?dl=0

https://www.dropbox.com/s/w88li8rfedsh2rj/Firewall-Forward.jpg?dl=0

Try this, I forget how to post pics. I suspect the brown patch (see top half of the first pic) may illustrate the extent of a possible crack. I think this was the bit that remained with the wheel. The lower part of the first pic is the bit attached to the firewall. It happened on a grass strip, so this lower shot may just be mud.

https://www.dropbox.com/s/ovo6t5p0soq9ys4/Noseleg.jpg?dl=0

https://www.dropbox.com/s/w88li8rfedsh2rj/Firewall-Forward.jpg?dl=0

Last edited:

PilotBrent

Well Known Member

Bottom skin is damaged which I think is one large piece. Maybe rebuilding the entire fuselage section is more straightforward way to go. Might be easier than trying to match some of the new with existing parts. Either way, very sorry you are facing this.

gblwy

Well Known Member

Back to the workshop...

I've ordered all the forward fuselage parts, cowling parts, step bulkhead and both side skins - and numerous other smaller parts. All three firewall sections are bent as is the floor, the instrument panel base and tunnel. The tunnel walls pushed back and damaged the step bulkhead. Aft of that looks OK. Parts availability is the issue, I reckon I can "just" replace all bent bits.

I've ordered all the forward fuselage parts, cowling parts, step bulkhead and both side skins - and numerous other smaller parts. All three firewall sections are bent as is the floor, the instrument panel base and tunnel. The tunnel walls pushed back and damaged the step bulkhead. Aft of that looks OK. Parts availability is the issue, I reckon I can "just" replace all bent bits.

Piper J3

Well Known Member

I wonder if this is first RV-12 nose gear to break in that location. The new revised strut has a secondary tube welded inside at the radius bend leading into the lower mounting flange. Wouldn't help in this instance.

Maybe Van's will chime in. Hoping not another SB...

Maybe Van's will chime in. Hoping not another SB...

Any part of any airplane can be broken if the loads the part was designed for are exceeded.

The damage in these photos looks very similar to other RV-12’s whose nose gear has made an uncontrolled abnormal contact with the ground.

If the leg is stabbed into the ground a sufficient amount, the inertial mass of the airplane causes the hollow leg to fold because of the overload. Sharply folding the tube causes it fracture at the fold.

The damage visible on the fwd fuselage is also similar to others I have seen though maybe a bit worse.

Unfortunate, but very repairable.

Like you said, just replace any parts that are bent, and fortunately, with the way the RV-12 is constructed, that is a much simpler process than i would be on many other aircraft..

The damage in these photos looks very similar to other RV-12’s whose nose gear has made an uncontrolled abnormal contact with the ground.

If the leg is stabbed into the ground a sufficient amount, the inertial mass of the airplane causes the hollow leg to fold because of the overload. Sharply folding the tube causes it fracture at the fold.

The damage visible on the fwd fuselage is also similar to others I have seen though maybe a bit worse.

Unfortunate, but very repairable.

Like you said, just replace any parts that are bent, and fortunately, with the way the RV-12 is constructed, that is a much simpler process than i would be on many other aircraft..

RFSchaller

Well Known Member

Bummer, Keith. I hope you’re back in the air soon.

NinerBikes

Well Known Member

Any part of any airplane can be broken if the loads the part was designed for are exceeded.

The damage in these photos looks very similar to other RV-12’s whose nose gear has made an uncontrolled abnormal contact with the ground.

If the leg is stabbed into the ground a sufficient amount, the inertial mass of the airplane causes the hollow leg to fold because of the overload. Sharply folding the tube causes it fracture at the fold.

The damage visible on the fwd fuselage is also similar to others I have seen though maybe a bit worse.

Unfortunate, but very repairable.

Like you said, just replace any parts that are bent, and fortunately, with the way the RV-12 is constructed, that is a much simpler process than i would be on many other aircraft..

To the extent of the damage observed, would the newer reinforced landing leg have made any difference in the resultant damage, in your expert opinion, Scott? Or was this just a really hard landing or a possible nose first landing, instead of main gear.

would the newer reinforced landing leg have made any difference in the resultant damage

Probably not.

The re-enforcement and other changes to the leg are quite a distance away from where the leg folded and broke.