Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starting Sequence for Dual P-Mag Ships

- Thread starter rockitdoc

- Start date

Carl Froehlich

Well Known Member

Both pMags on, prime (if cold) using the boost pump, then hit the start button. I use a toggle switch for each ignition and a starter push button - hate old school key ignition switches.

Carl

Carl

rapid_ascent

Well Known Member

We have a standard ignition/start switch.

On the switch panel with all the lights, strobes, avionics etc, we have 2 switches for the P-Mags.

All our switches are switch breakers to avoid duplication btw.

Master on

Mixture rich

Fuel pump on - throttle advance to show fuel flow.

Fuel pump off - Leave mixture rich.

Throttle 1/4" open

Keep the start key turned until it starts......

Bingo every time when cold !

On the switch panel with all the lights, strobes, avionics etc, we have 2 switches for the P-Mags.

All our switches are switch breakers to avoid duplication btw.

Master on

Mixture rich

Fuel pump on - throttle advance to show fuel flow.

Fuel pump off - Leave mixture rich.

Throttle 1/4" open

Keep the start key turned until it starts......

Bingo every time when cold !

No Alt or Avionics switches? If so, when do they get turned on?We have a standard ignition/start switch.

On the switch panel with all the lights, strobes, avionics etc, we have 2 switches for the P-Mags.

All our switches are switch breakers to avoid duplication btw.

Master on

Mixture rich

Fuel pump on - throttle advance to show fuel flow.

Fuel pump off - Leave mixture rich.

Throttle 1/4" open

Keep the start key turned until it starts......

Bingo every time when cold !

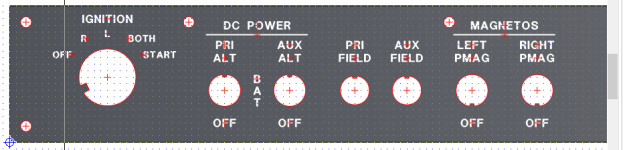

No master?Here is a pic of my planned arrangement.

View attachment 10124

The PMAG switches on the right are the momentary test switches.

rapid_ascent

Well Known Member

My marking may be confusing you. My "master" is the PRI ALT switch under the DC Power section. This is a 3 position switch where the middle position is the BAT only. The AUX ALT switch is also a 3 position switch that works similarly, but performs the cross-feed connection and powers the Endurance Bus. This is essentially a Z-13 schematic.

No Alt or Avionics switches? If so, when do they get turned on?

Alt is in the Cessna split Master Switch.

Avionics Master after start.

Exactly as Carl on my RV-8/IO-360/AFP200/Dual Pmags:Both pMags on, prime (if cold) using the boost pump, then hit the start button. I use a toggle switch for each ignition and a starter push button - hate old school key ignition switches.

Carl

Master/Alt on

L and R Pmags on

Start button

Fly

Carl Froehlich

Well Known Member

No Alt or Avionics switches? If so, when do they get turned on?

So, you want details!

Sequence:

- Left master on

- Right master on

- Left vital bus on (brings up the left EFIS and power to flaps and COMM #2, it will be on during engine start)

- Right vital off (leaves the right EFIS off but more importantly leaves the expensive GTN-650 off as I do not have confidence that it is immune to voltage sag during start).

- Flaps up

- Left ignition on

- Right ignition on

- Throttle cracked open, mixture at ICO

- Boost bump on

- Mixture to full rich for ~5 seconds to prime, then back to ICO (no prime for hot start)

- Start button, crank engine, mixture to half open after engine start

- After start, right vital on.

- Lean to just before engine stops (minimizes plug fouling and stuck exhaust valve issues.

Carl

Exactly as Carl on my RV-8/IO-360/AFP200/Dual Pmags:

Master/Alt on

L and R Pmags on

Start button

Fly

When do avionics and fuel pump get turned on?

Av8rRob

Well Known Member

When do avionics and fuel pump get turned on?

I do the purge/prime with my electric fuel pump and the AFP purge valve depending on the engine temp. I don't run the electric fuel pump at startup - just the mechanical fuel pump.

I don't have an avionics master, but my GRT EFIS, EIS 4000, and Safefly2020 are on the IBBS, and I turn that on as soon as I get into the cockpit, along with my battery powered CO sensor.

After the engine is running, I power on the radio, transponder, NAV and wig-wag. I also add power to the flaps, trim, and A.P. servos.

Back to the PMAGS, I test them L-R-Both during the run-up. Each test includes testing the internal generator since my switch positions are from bottom to top: off | on-internal-generator | on-12v-ship-power

Basically, I can't test them without testing the generator each time. From time to time I test at idle to ensure that the middle position is actually the generator - this turns off the pmag.

Really happy with my config - I'd do it the same way - very "idiot proof".

Last edited:

rapid_ascent

Well Known Member

Based upon the questions here I realized maybe my ALT switch labeling wasn't as obvious as it should be so I changed it to MASTER / PRI ALT and EBUS / AUX ALT. Sometimes its good to have others perspective even for the simple things. Thx.

Toobuilder

Well Known Member

When I had dual Pmags I simply turned the standard key to "start". No sense in making a Shuttle launch out of simply starting an airplane.

Since I have Space Shuttle switch guards, I pretend I'm Bob Crippen at every startup.... No sense in making a Shuttle launch out of simply starting an airplane.

https://periheliondesign.com/product/organic-handpicked-coffee/

Carl Froehlich

Well Known Member

I’m curious. It seems many have an alternator switch that they turn on after engine start. On all three of my RVs I just have an alternator breaker that is always on (as in I never open the alternator breaker unless I’m testing something).

So why do many turn on the alternator after engine start?

Carl

So why do many turn on the alternator after engine start?

Carl

Larry DeCamp

Well Known Member

+1 for Carls point

B&C advised me the Alt powered from the master bus is fine and they do recommend a 5AMP breaker in the field power due to transients that do happen .

B&C advised me the Alt powered from the master bus is fine and they do recommend a 5AMP breaker in the field power due to transients that do happen .

I’m curious. It seems many have an alternator switch that they turn on after engine start. On all three of my RVs I just have an alternator breaker that is always on (as in I never open the alternator breaker unless I’m testing something).

So why do many turn on the alternator after engine start?

Carl

I do it for better starting performance. When you hit the starter, bus voltage drops to 10 or lower. This causes the alternator to go to max output. First, it will draw close to 5 amps on the field, robbing current from the starter (likely a non issue) and second, it adds a good amount of torque drag to the engine, slowing down the cranking RPM. A 60 amp alt probably requires 3 HP at full output. Modern auto systems now use the EFII computer to control alt output and use a soft start ramp up and likely disable the field while cranking to achieve similar results.

My portable generator requires a 12 HP engine to produce 4400 watts. A 60 amp alternator is producing just under 1000 watts, so back of the napkin math says around 3 HP to drive it. At starting RPMs, it can probably only produce 15 amp, maybe 20.. Your starter is drawing around 250 amps@10 volts, so 2500 watts. Your alternator is robbing 300 watts or a bit over 10% of the starter power. Disconnecting the field eliminates that drain and provides better starting RPM. To me, this is very meaningfull in the Chicago winters, where it is harder to gauge required prime (potentially more cranking to get it right) and reduced battery output due to low temps.

I have 750 hours on my $35 ND alternator with ext regulator and this procedure has not apparently reduced it's longevity. I do not disconnect the field before shutdown, as I speculate that may not be good for the regulator due to a large collapsing magnetic field (not sure if the rectifier bridge shunts this). A traditional engine shutdown is more gentle.

Larry

Last edited:

Carl Froehlich

Well Known Member

Seems like the mag on/off switches are redundant with the key switch. Why have both? And, I assume you have E-mags with self-powering internal alternators?

If you have an old school key switch (off, left, right, both, start) there is no need for separate ignition switches. Many people (me included) do not like the old school key switch.

If you do have a key switch, at least rewire it so you start on both pMags.

Carl

MED

Well Known Member

Seems like the mag on/off switches are redundant with the key switch. Why have both? And, I assume you have E-mags with self-powering internal alternators?

You want a switch for each p-mag to disable ship’s power to confirm the internal generator is operating.

Carl Froehlich

Well Known Member

You want a switch for each p-mag to disable ship’s power to confirm the internal generator is operating.

I just pull the associated breaker to do this simple test from time to time.

Carl

I'm old school and use the key switch, split master and two switch-breakers for my dual P-mags.

For the Before Takeoff Checklist, I run the engine up to 1700, turn the P-mag switch-breakers off, do the L-R-Both check, then switch-breakers on and power to idle.

If I forget to put the switch-breakers back on before idle it gets real quiet (and I get embarrassed).

For the Before Takeoff Checklist, I run the engine up to 1700, turn the P-mag switch-breakers off, do the L-R-Both check, then switch-breakers on and power to idle.

If I forget to put the switch-breakers back on before idle it gets real quiet (and I get embarrassed).

Attachments

pfactor

Well Known Member

still building ... but wired these in w 3amp CBs as per wiring details at bottom of pages..

https://www.steinair.com/product/locking-toggle-switch-p-mag-test-on-on-mom/

also non locking a bit cheaper...

https://www.steinair.com/product/s700-2-50-switch/

/Andy

https://vansairforce.net/community/showthread.php?t=170343

https://www.steinair.com/product/locking-toggle-switch-p-mag-test-on-on-mom/

also non locking a bit cheaper...

https://www.steinair.com/product/s700-2-50-switch/

/Andy

https://vansairforce.net/community/showthread.php?t=170343

Last edited:

MED

Well Known Member

I just pull the associated breaker to do this simple test from time to time.

Carl

I have momentary off switches, so I check at each run-up. Adds 2 seconds to each p-mag check.

Last edited: