Same here...

I did exactly the same...

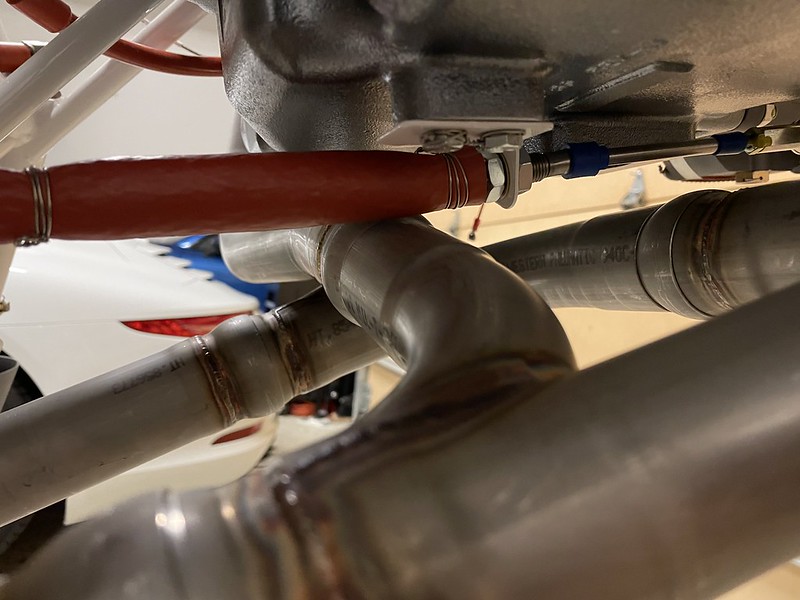

I have a beautyfully trimmed CB-1002A that fits perfectly to the cowl, but it's too short now...

Thinking about a way around it, maybe by adding a doubler to increase its lenght???

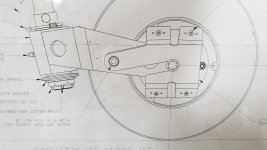

Here's a gotcha for builders going with the horizontal air induction system snorkel. If you follow the directions on installing the baffles, you'll end up with a beautifully trimmed set of baffles, including the front-left inlet ramp (CB-1002A). Then, when you go to install the snorkel, you'll notice step 1 says "NOTE: Do not trim the length of part 2 Left Front Inlet Floor at this time". Of course they are talking about one of the baffle parts you just trimmed. Save $25+shipping by not trimming that piece.

I did exactly the same...

I have a beautyfully trimmed CB-1002A that fits perfectly to the cowl, but it's too short now...

Thinking about a way around it, maybe by adding a doubler to increase its lenght???