claycookiemonster

Well Known Member

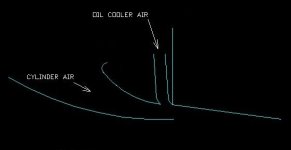

I see many mounts and placements for oil coolers, but they all end at the cooler. Air is blown on it, and then...? The interior of a cowling, particularly below the engine has got to be a very turbulent place, and we're just dumping more turbulent warm air into it at the cooler.

Has anyone installed any kind of ductwork downstream of the oil cooler? It occurs to me that some sort of plenum full of warm air could extend to near the cowl exit where we could depend on a low pressure area to pull the air out of the cooler chamber. (P-51 afficionadoes might even achieve the purported thrust that aircraft was said to achieve by it's radiator)

It might only take 12 - 18" of ducting to lead the oil cooler exit flow near the cowl exit to assist the flow through the cooler as well as keeping that part of the heat somewhat contained?

Or, am I (ah-hem) full of hot air?

Has anyone installed any kind of ductwork downstream of the oil cooler? It occurs to me that some sort of plenum full of warm air could extend to near the cowl exit where we could depend on a low pressure area to pull the air out of the cooler chamber. (P-51 afficionadoes might even achieve the purported thrust that aircraft was said to achieve by it's radiator)

It might only take 12 - 18" of ducting to lead the oil cooler exit flow near the cowl exit to assist the flow through the cooler as well as keeping that part of the heat somewhat contained?

Or, am I (ah-hem) full of hot air?