Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

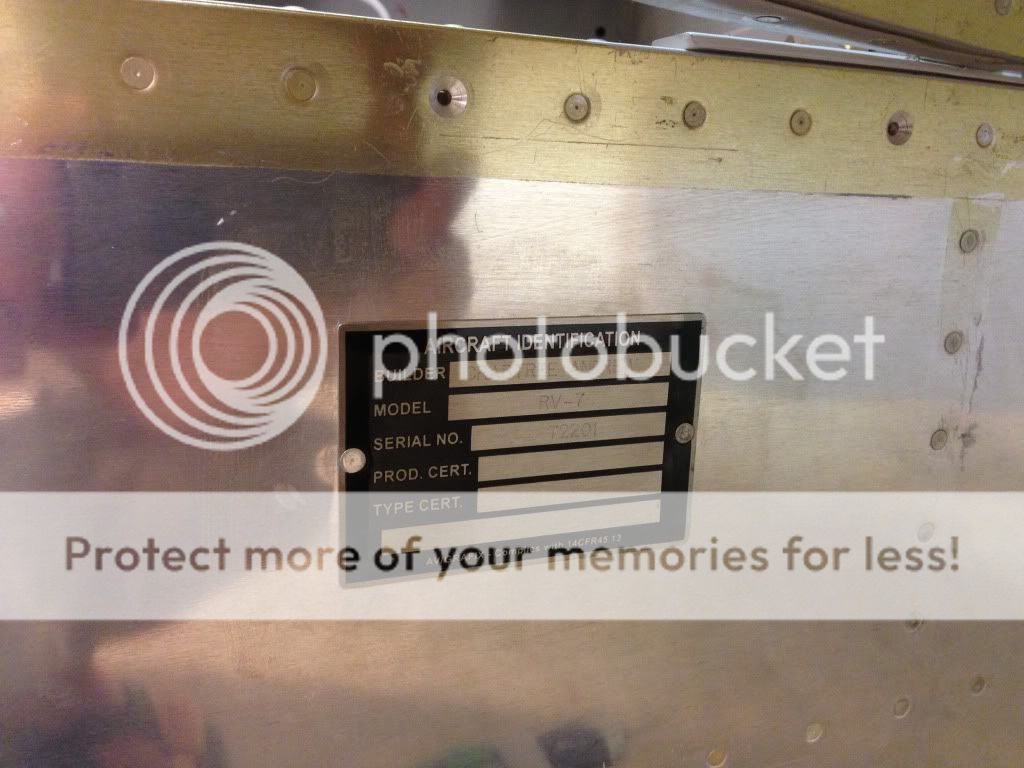

RV-7 N117TR

- Thread starter crabandy

- Start date

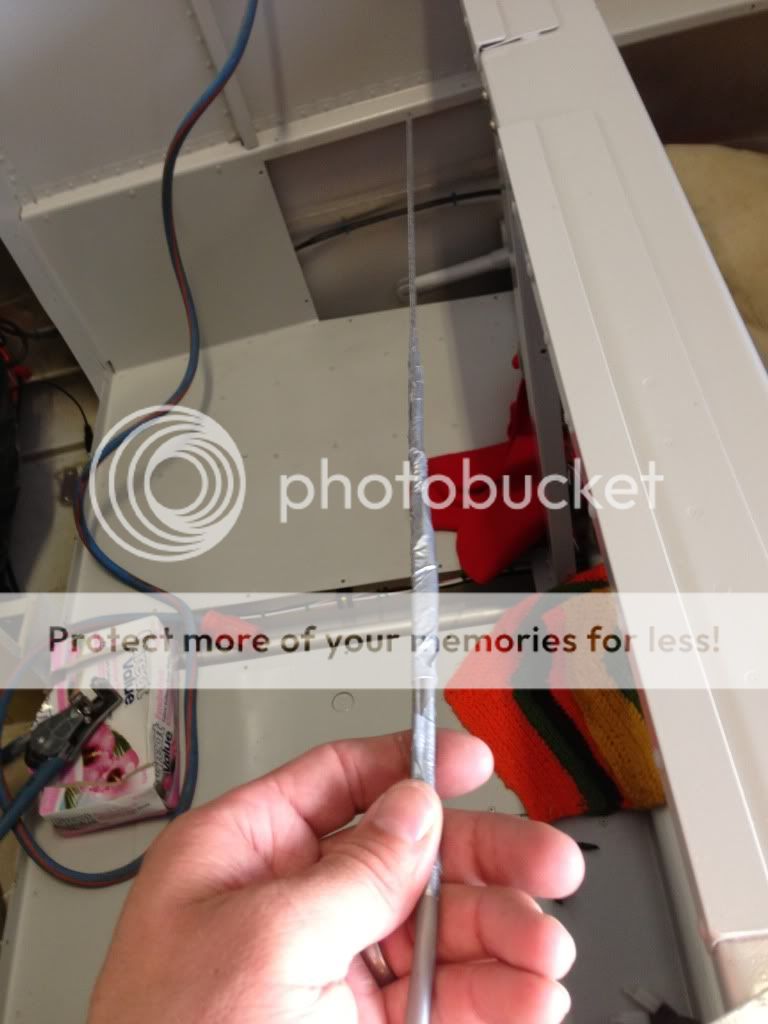

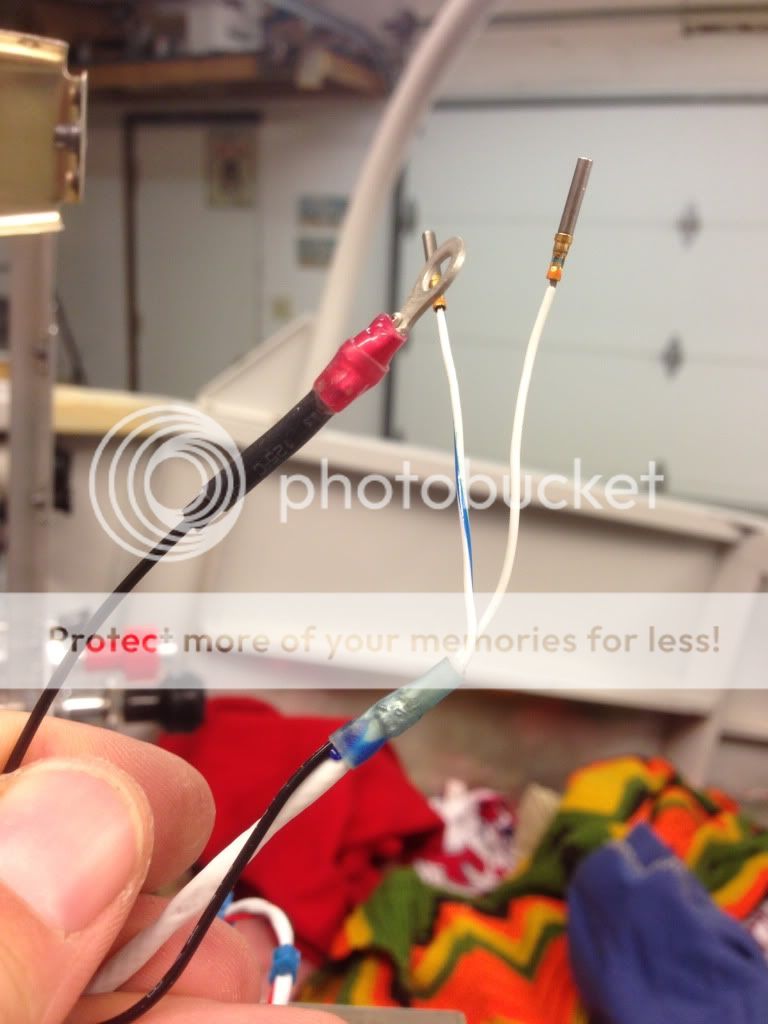

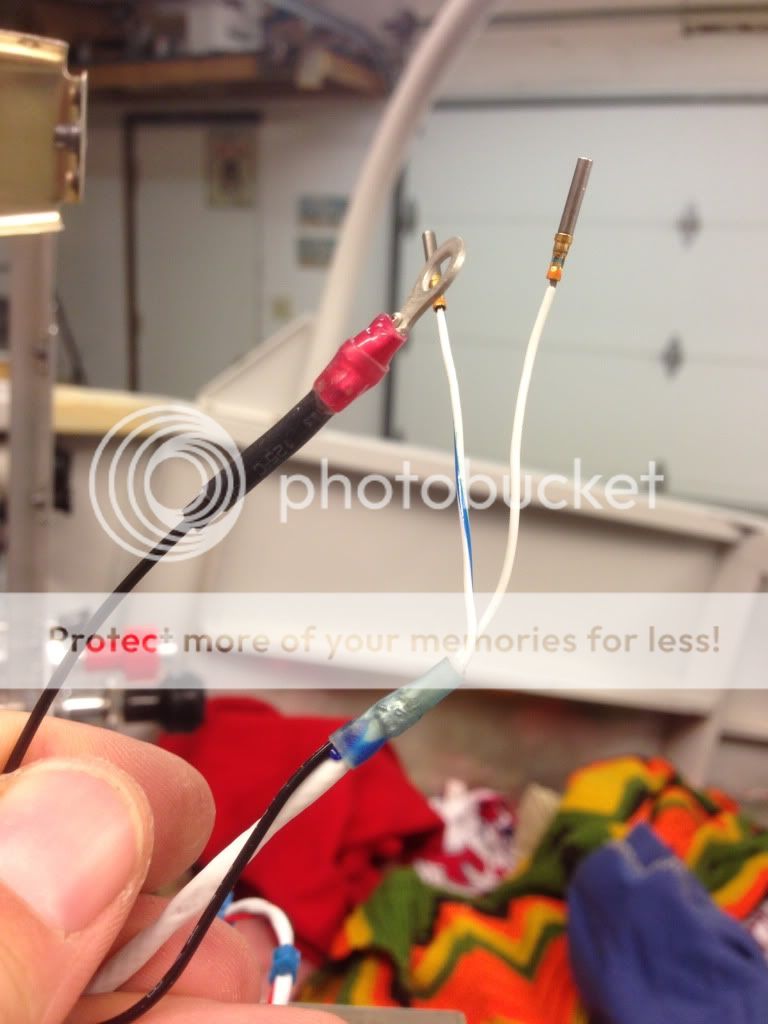

I made the fusable links for the shunt. Aeroelectric says 4 sizes smaller for a fusable link, the sensor wire is already 22 awg. Consensus on VAF said a 24 awg link is acceptable.

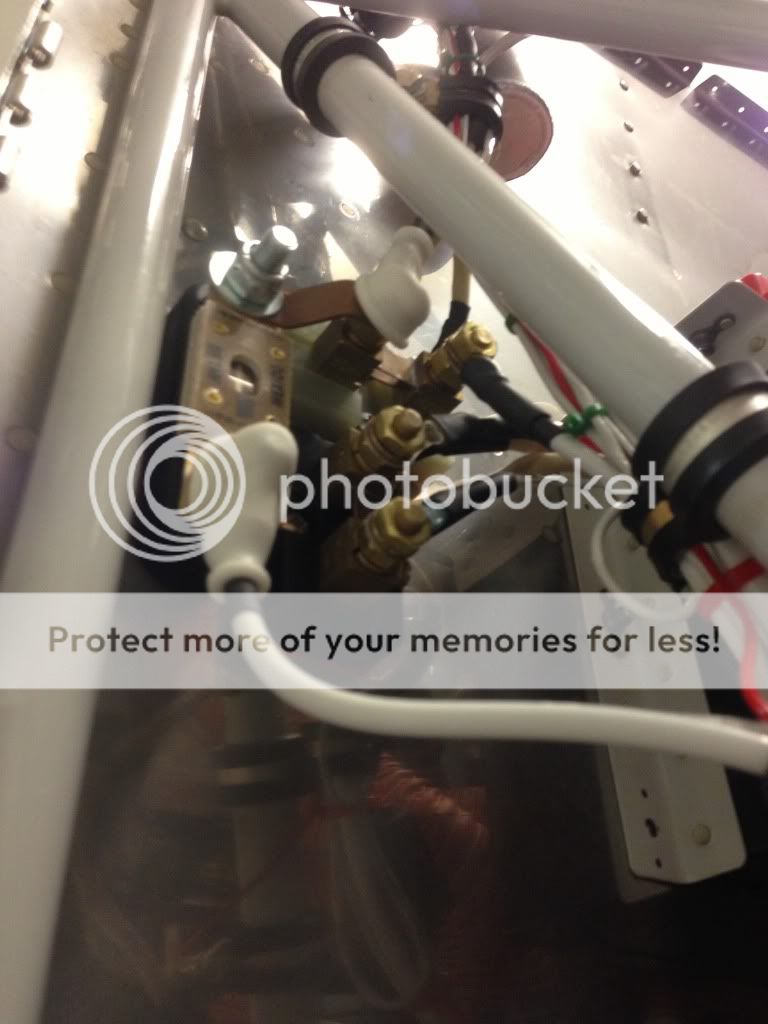

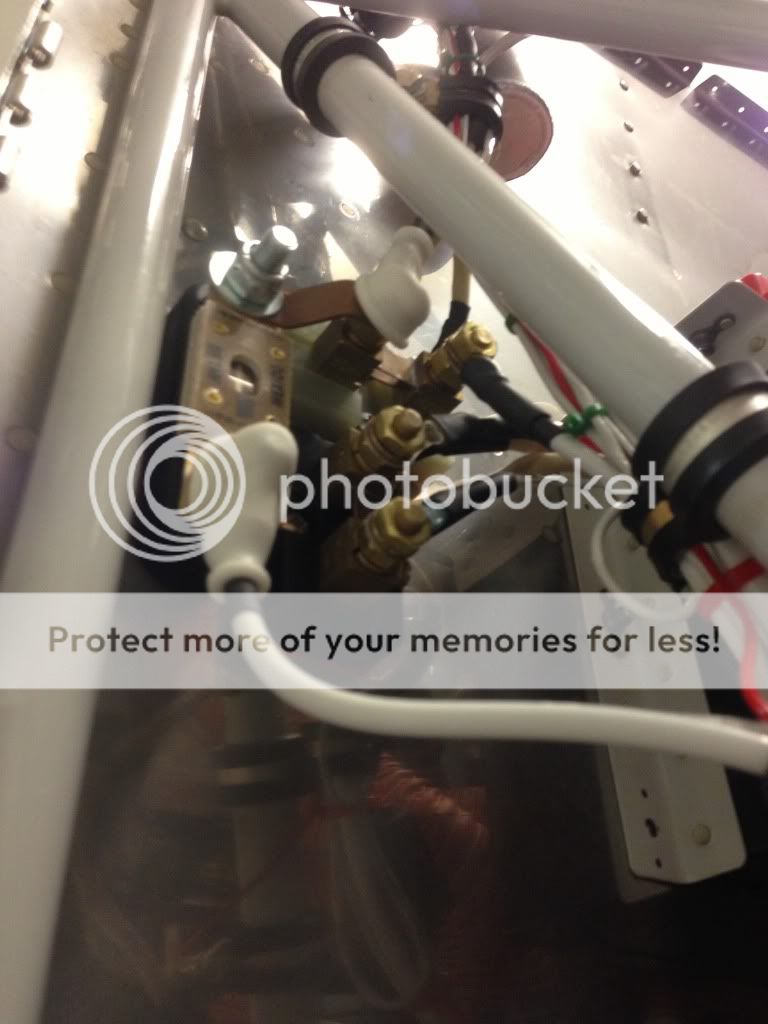

I cleaned up the wiring in the center tunnel and installed the push-pull tube.

Flap actuator installed and wired, I might install a flap position thingie so I can display my flaps on the G3X.

I also configured my elevator trim tab on the G3X and confirmed my shunt wires were hooked up properly.

I cleaned up the wiring in the center tunnel and installed the push-pull tube.

Flap actuator installed and wired, I might install a flap position thingie so I can display my flaps on the G3X.

I also configured my elevator trim tab on the G3X and confirmed my shunt wires were hooked up properly.

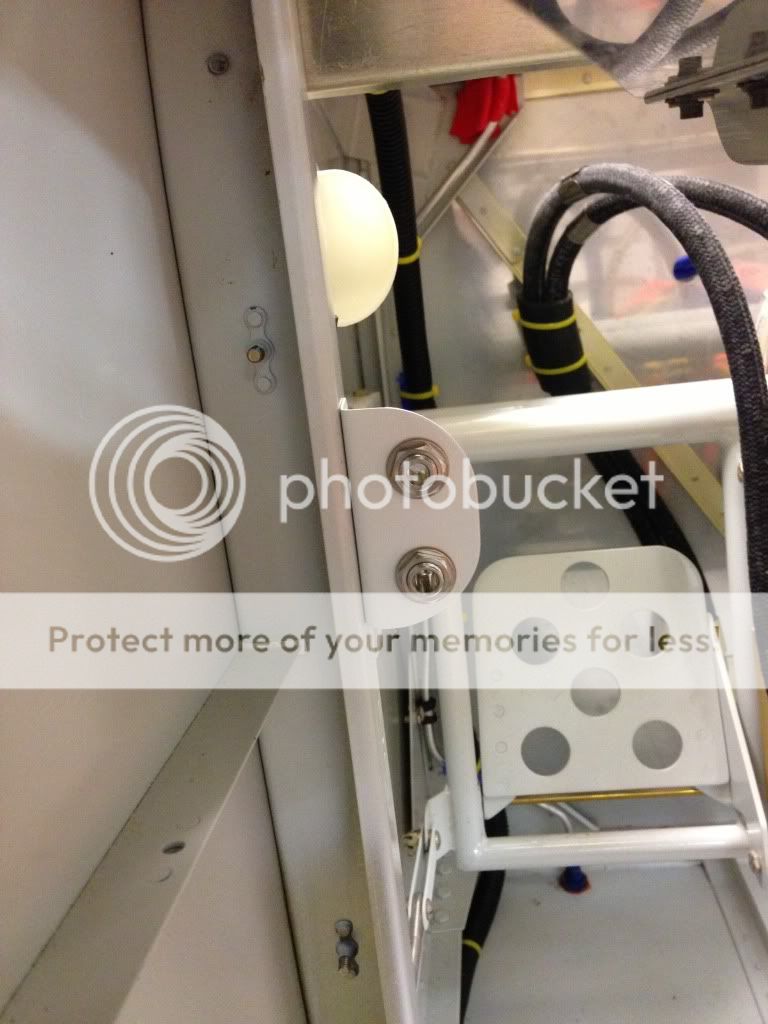

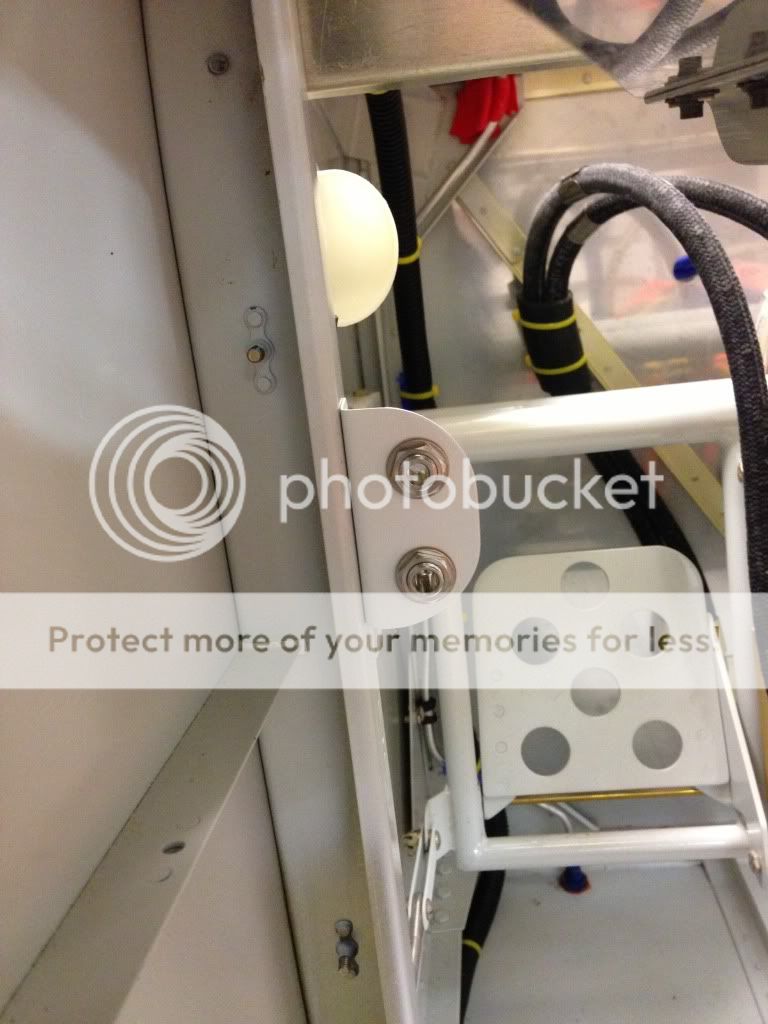

Long day at work, I kinda wondered about the garage for a couple of hours. I was finally able to get something accomplished, finalized the headset jack location underneath the subpanel. I sat in the airplane with a headset for a while and this seemed to be the best place for entry/exit/inflight. The cords hang out of the way in use and I can set the headset on the floor next to the spar for entry and exit. I was going to make a hanger below the jacks bu the floor was out of the way and already done!

jack location

Think you have the right spot. I went to a lot of trouble this winter to add headsets jacks behind the seats. Turns out the cables are more of a pain back there than up front as they get twisted up and tangled with cargo and are much harder to reach especially when in flight. I now use the clarity aloft in my front jacks and find the keeping the cables straight much easier when they are in front of you.

Think you have the right spot. I went to a lot of trouble this winter to add headsets jacks behind the seats. Turns out the cables are more of a pain back there than up front as they get twisted up and tangled with cargo and are much harder to reach especially when in flight. I now use the clarity aloft in my front jacks and find the keeping the cables straight much easier when they are in front of you.

BillL

Well Known Member

Flap Position Sensor

Andy, here is how I mounted my flap sensor. It is the Ray Allen unit. I could not visualize the geometry so I made a dimension sketch to keep the line of action of the slider near as possible. The mount is a fabricated 30-60 triangle shape and located so the slide points to the pivot connection. The pivot needs to be over the top of the weld, so I fabbed a block from a kitchen cutting board by drilling a hole with a hole saw. The other pivot is made from hardware angle, and small bolts from the RC model shop. I drilled several holes to allow adjustment so it would not reach the limit and adjusted the RC model link to the center. I can provide some more detail if you are interested.

I thought about making these to sell, but with the time involved, decided most would just make their own anyway.

Andy, here is how I mounted my flap sensor. It is the Ray Allen unit. I could not visualize the geometry so I made a dimension sketch to keep the line of action of the slider near as possible. The mount is a fabricated 30-60 triangle shape and located so the slide points to the pivot connection. The pivot needs to be over the top of the weld, so I fabbed a block from a kitchen cutting board by drilling a hole with a hole saw. The other pivot is made from hardware angle, and small bolts from the RC model shop. I drilled several holes to allow adjustment so it would not reach the limit and adjusted the RC model link to the center. I can provide some more detail if you are interested.

I thought about making these to sell, but with the time involved, decided most would just make their own anyway.

Last edited:

Safetied the prop bolts, I was putting this off because I know I'm going to need a heavier crush plate to help with an aft cg. Need to finish and weigh it first I suppose.

I soldered the wires to the headset/mike jacks. I used the aeroelectric/Garmin/Stein/Mentor to figure out the wiring for these. I found these nifty angled "Kelly clamps" at Air Parts in KC for $3.50, I've got a straight pair as well and love them for adel clamps among other things.

I only drilled the holes in the jack brackets to 3/8 but I had to enlarge it to 7/16 so the shoulder on the isolating washer would fit. An plastic/fabric isolating washer on each side of the jack is used to insulate the jack from grounding on the airframe (I think).

I soldered the wires to the headset/mike jacks. I used the aeroelectric/Garmin/Stein/Mentor to figure out the wiring for these. I found these nifty angled "Kelly clamps" at Air Parts in KC for $3.50, I've got a straight pair as well and love them for adel clamps among other things.

I only drilled the holes in the jack brackets to 3/8 but I had to enlarge it to 7/16 so the shoulder on the isolating washer would fit. An plastic/fabric isolating washer on each side of the jack is used to insulate the jack from grounding on the airframe (I think).

Last edited:

Attempting to make some Aluminum windscreen fairings, we will see how it goes.

I taped some oversized poster board onto the plexi then used a scap piece of aluminum to fine the plexi/skin intersect point. I've got the fairings cut, we'll see tomorrow if I can bend them to fit.

My SD8 was hand delivered today by William of B and C Specialties on his way to KC. Pretty cool service! I can't wait to get it installed.

I taped some oversized poster board onto the plexi then used a scap piece of aluminum to fine the plexi/skin intersect point. I've got the fairings cut, we'll see tomorrow if I can bend them to fit.

My SD8 was hand delivered today by William of B and C Specialties on his way to KC. Pretty cool service! I can't wait to get it installed.

I mostly referred to this posting for info on how to do the aluminum windscreen fairings

https://picasaweb.google.com/m/view...hkey:Gv1sRgCOrUkIa2g-KjJA/5609409801837447890

After mounting the windscreen, I taped some construction paper to the windscreen slightly overlapping the front skin. I used a small (1 inch) piece of scrap aluminum to lay onto the windscreen and find it's intersection point with the top skin. I made 1 inch dashes all around the construction paper, as well as referenced common rivet holes to make sure my templates were symmetrical. I used tape for some reference lines and roughly measured the angles at the reference lines. I removed the construction paper and cut my curved windscreen to top skin line, traced onto the aluminum and projected the curved line 20/32 lower on the aluminum and cut.

I cut and sanded a piece of styrofoam to match the windscreen top skin curve and cut a 2x6 with the same curve.

I doubled up the rollers with longer screws on this edge former to make the bent flange. I almost messed up, I rolled the edge about 5 degrees on the flat table first. When I went to check the fit, I found it didn't want to bend around the windscreen hence the 2x6 cut to the curve.

The curve on the 2x6 doesn't have to be exact, mine was a loose 1/8 inch. The wood form will not match the curve on the aluminum, just stick it out the front enough that the edge roller can make it around the radius. The bend is accomplished with the roller, not the 2x6. The 2x6 holds the curve while you bend the flange. It took about 20 min solid of rolling and sweating, way less mess than sanding though.

So far I think they look pretty good!

I had to use a hole finder to drill the existing holes on the longerons.

I left the aft edges and top oversized to trim later.

I still have to trim the fairings down and decide wether to drill or glue the windscreen.

https://picasaweb.google.com/m/view...hkey:Gv1sRgCOrUkIa2g-KjJA/5609409801837447890

After mounting the windscreen, I taped some construction paper to the windscreen slightly overlapping the front skin. I used a small (1 inch) piece of scrap aluminum to lay onto the windscreen and find it's intersection point with the top skin. I made 1 inch dashes all around the construction paper, as well as referenced common rivet holes to make sure my templates were symmetrical. I used tape for some reference lines and roughly measured the angles at the reference lines. I removed the construction paper and cut my curved windscreen to top skin line, traced onto the aluminum and projected the curved line 20/32 lower on the aluminum and cut.

I cut and sanded a piece of styrofoam to match the windscreen top skin curve and cut a 2x6 with the same curve.

I doubled up the rollers with longer screws on this edge former to make the bent flange. I almost messed up, I rolled the edge about 5 degrees on the flat table first. When I went to check the fit, I found it didn't want to bend around the windscreen hence the 2x6 cut to the curve.

The curve on the 2x6 doesn't have to be exact, mine was a loose 1/8 inch. The wood form will not match the curve on the aluminum, just stick it out the front enough that the edge roller can make it around the radius. The bend is accomplished with the roller, not the 2x6. The 2x6 holds the curve while you bend the flange. It took about 20 min solid of rolling and sweating, way less mess than sanding though.

So far I think they look pretty good!

I had to use a hole finder to drill the existing holes on the longerons.

I left the aft edges and top oversized to trim later.

I still have to trim the fairings down and decide wether to drill or glue the windscreen.

Last edited:

I got the windscreen fairings drilled to the windscreen, deburred, countersunk etc.

I bought these little Herbie clips to clamp the vacuum line for my manifold pressure sensors. When I inventoried the bag I thought it odd that the inside of he bag was all wet, directions actually say to store wet to aid in installation. They seem to grip the smaller diameter tubing pretty well, we will see how they hold up.

I obviously didn't pre-plan my electrical system well enough, I was going to be close on fuse slots. I added another 8 slot fuse block powered from the main bus just in case to allow for future upgrades.

I bought these little Herbie clips to clamp the vacuum line for my manifold pressure sensors. When I inventoried the bag I thought it odd that the inside of he bag was all wet, directions actually say to store wet to aid in installation. They seem to grip the smaller diameter tubing pretty well, we will see how they hold up.

I obviously didn't pre-plan my electrical system well enough, I was going to be close on fuse slots. I added another 8 slot fuse block powered from the main bus just in case to allow for future upgrades.

It's amazing how busy all of the wiring gets, I've attempted to run it orderly and with a purpose.....not too bad for my first one but my next plane will be better!

My dual EFII ignition only came with 1 RPM output. I emailed Robert at EFII about this, my G3X has 2 inputs and I wanted to have an RPM reading even if I was only using 1 ignition like on run up. I can't say enough about the great customer service from Robert at EFII, even during Oshkosh within an hour or two I had a 100% solution to my email. Several days later I received 2 wires and a connector in the mail free of charge. 1 wire needed to be soldered in the DB25 connector to the 22 pin of the 71 ECU to provide a Second RPM output and the second wire in the connector snapped into the 71 ECU and hooked to ground.

Here's a pic of my crappy first time soldering of Dsub pins, I bet you can find pin22 that I soldered, not pretty but she's solid.

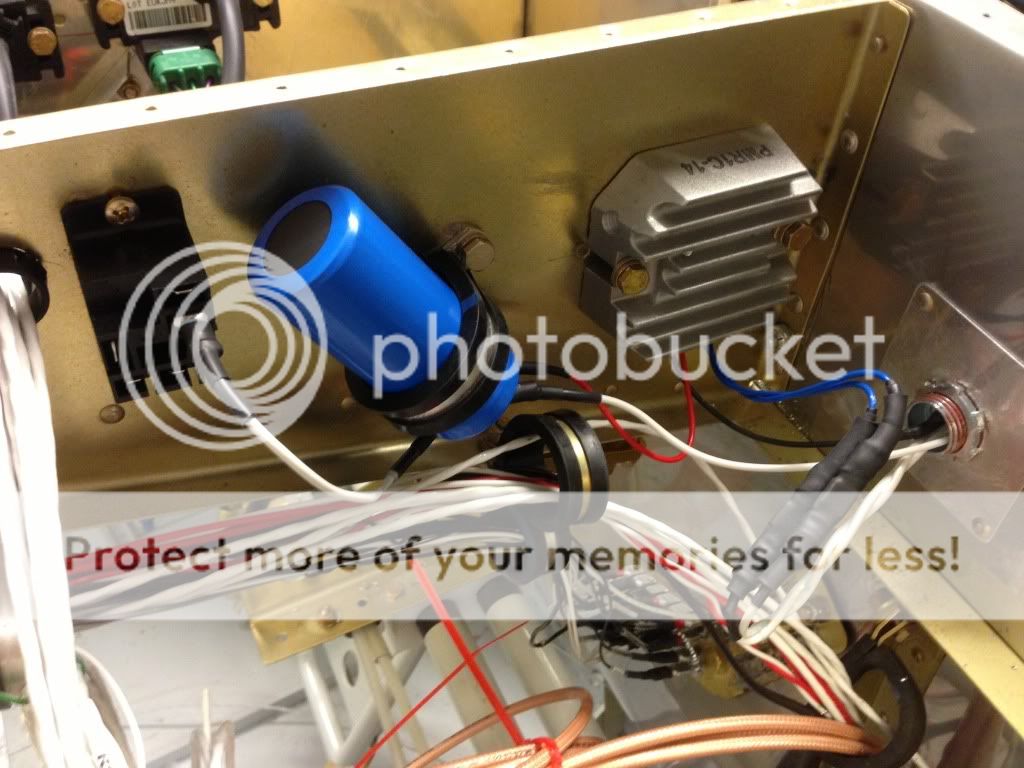

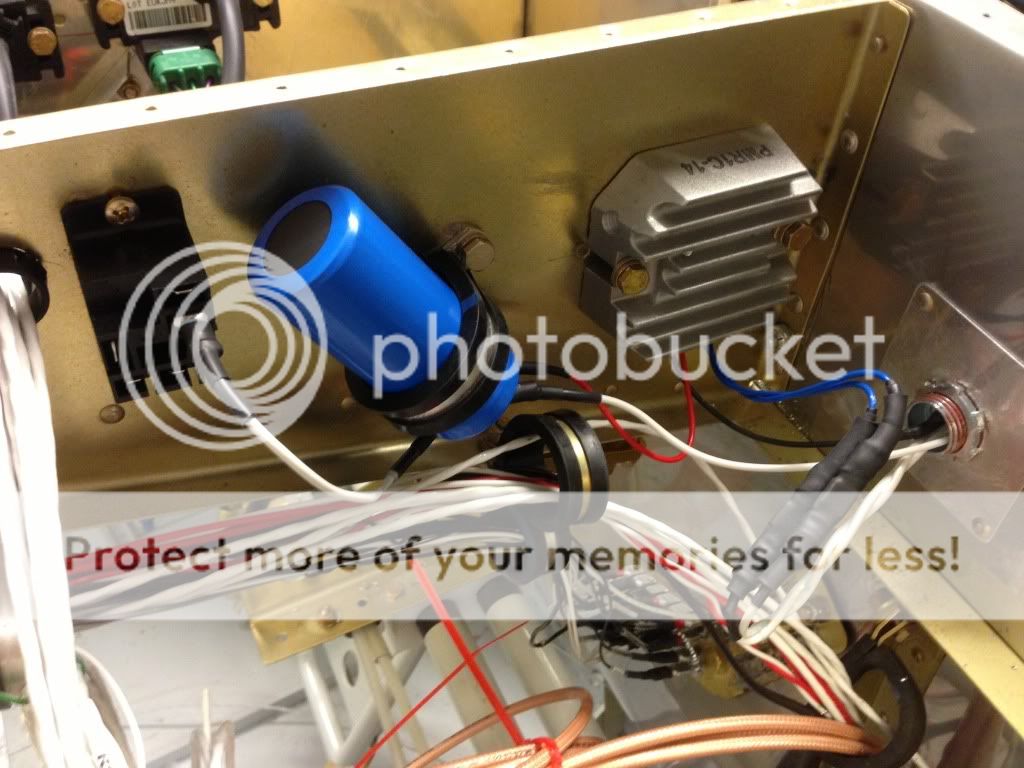

I removed my vacuum pump cover plate to install the SD-8, my accessory case is slightly different with the single mag. The SD-8 bolted right up with a little finger yoga.

The instructions say to mount the regulator/capacitor/relay behind the firewall (strongly suggested). I was going to mount on the front side of the firewall but caved in and told myself if I mounted the regulator/capacitor/relay on the center rib inside I will comply with the instructions and I won't have to install nut plates on the firewall. Just 4 rivets for a doubler and a big hole for a firewall pass through. I've got it about halfway wired.

My dual EFII ignition only came with 1 RPM output. I emailed Robert at EFII about this, my G3X has 2 inputs and I wanted to have an RPM reading even if I was only using 1 ignition like on run up. I can't say enough about the great customer service from Robert at EFII, even during Oshkosh within an hour or two I had a 100% solution to my email. Several days later I received 2 wires and a connector in the mail free of charge. 1 wire needed to be soldered in the DB25 connector to the 22 pin of the 71 ECU to provide a Second RPM output and the second wire in the connector snapped into the 71 ECU and hooked to ground.

Here's a pic of my crappy first time soldering of Dsub pins, I bet you can find pin22 that I soldered, not pretty but she's solid.

I removed my vacuum pump cover plate to install the SD-8, my accessory case is slightly different with the single mag. The SD-8 bolted right up with a little finger yoga.

The instructions say to mount the regulator/capacitor/relay behind the firewall (strongly suggested). I was going to mount on the front side of the firewall but caved in and told myself if I mounted the regulator/capacitor/relay on the center rib inside I will comply with the instructions and I won't have to install nut plates on the firewall. Just 4 rivets for a doubler and a big hole for a firewall pass through. I've got it about halfway wired.

Last edited:

I put the SD8 Shunt next to the Shunt for the main Alt. The main shunt reads like a +/- amps into/out of the Batt, the aux alt shunt is wired to show output from the aux alt. The other side of aux alt shunt is connected to the Batt side of the master contactor.

I swear these engine mount gussets next to the lower outboard corner of the engine mount have some sort of magnetic pull for any and all AN hardware.

If I can't find a dropped nut/screw/washer/bolt/electrical terminal etc on the floor this is my go to place. Mirror and flashlight with some fishing with toothpicks usually finds the missing hardware. I'm a slow learner, masking tape has fixed my problem, unless the magnetic field is too strong.

I swear these engine mount gussets next to the lower outboard corner of the engine mount have some sort of magnetic pull for any and all AN hardware.

If I can't find a dropped nut/screw/washer/bolt/electrical terminal etc on the floor this is my go to place. Mirror and flashlight with some fishing with toothpicks usually finds the missing hardware. I'm a slow learner, masking tape has fixed my problem, unless the magnetic field is too strong.

I made my first shielded wire termination with solder shields, pretty cool. Also used my new dsub crimper tool ($40ish), seems to work pretty well. Together they made my last connections for my SD8.

Ended the short work session torquing the alt right at 12 ft/lbs on the 5th try and safety wiring.

Ended the short work session torquing the alt right at 12 ft/lbs on the 5th try and safety wiring.

I cut my control sticks down to fit the Tosten grip, it's pretty short without the grip, here's the copilot side.

I lined the grip with my hand on the armrest, it's twisted right about 15 degrees. It's easy to change the angle later by loosening the pinch screws. The Tosten grip utilizes 1 Allen screw to pinch the pin on the grip, after I drilled and tapped the stick it seemed very secure. I drilled and tapped 2 more pinch screws for the grip, just to make sure it won't wobble/pull off. And yes I am wearing socks with flip flops!

I lined the grip with my hand on the armrest, it's twisted right about 15 degrees. It's easy to change the angle later by loosening the pinch screws. The Tosten grip utilizes 1 Allen screw to pinch the pin on the grip, after I drilled and tapped the stick it seemed very secure. I drilled and tapped 2 more pinch screws for the grip, just to make sure it won't wobble/pull off. And yes I am wearing socks with flip flops!

Jerry Fischer

Well Known Member

Wiring

Really very nice job and looks professional, you should have trouble free operation from your taking the time now to do it right

Really very nice job and looks professional, you should have trouble free operation from your taking the time now to do it right

I superglued the little steel washers to the rod ends, worked great!

I installed the manual aileron trim, pretty straightforward. I didn't have any .041 safety wire so I'll have to wire the springs later. I used a square on the spar as a vertical reference to keep the sticks straight while adjusting the rod end bearings.

I also wasted an hour trying to find a good spot for the cigarette lighter.

I installed the manual aileron trim, pretty straightforward. I didn't have any .041 safety wire so I'll have to wire the springs later. I used a square on the spar as a vertical reference to keep the sticks straight while adjusting the rod end bearings.

I also wasted an hour trying to find a good spot for the cigarette lighter.

I got the quick release button thingies from McMaster Carr instead of a pin for easy removal of the copilot stick. I drilled a 1/4 inch hole on one side of the copilot stick and mount, fits like a glove. (Thanks VAF for the idea)

I also found another spot for my cigarette lighter, behind the fuel valve in between the spars. I really hate cords dangling around the cockpit, this location should hopefully minimize this. I will probably dab some silicone on the wire passthroughs from the fuel valve area to keep fumes away just incase I get a leak.

I also found another spot for my cigarette lighter, behind the fuel valve in between the spars. I really hate cords dangling around the cockpit, this location should hopefully minimize this. I will probably dab some silicone on the wire passthroughs from the fuel valve area to keep fumes away just incase I get a leak.

I made a brace from the throttle/mixture cable bracket to the front of the FAB top plate to help keep it from cracking. I mocked it up with some scrap cardboard and had a usuable first piece out of aluminum.

I had originally sealed between the rear of the carb and the FAB top plate with silicone, the forum responses said I should use a thin layer of proseal instead. I finally got around to removing the FAB top plate and silicone and resealing with proseal.

I had originally sealed between the rear of the carb and the FAB top plate with silicone, the forum responses said I should use a thin layer of proseal instead. I finally got around to removing the FAB top plate and silicone and resealing with proseal.

BillL

Well Known Member

Andy, Congrats on the new little builder. You really don't sleep do you?

Comment and question: thanks for posting the nice clear pictures of your alternator installation. I now know where the safety wire holes can be drilled, so thanks!

I was just fitting mine a couple of days ago and found that the two 05-06 bolts that thread into the case and starter respectively needed additional washers to avoid interference with the case threads. I see yours only have one washer. I have the Vans supplied IO360 and threaded them up by hand only to find they would not thread down snug. The grip length on the bolts is greater than the thickness of the arms+washer. Maybe the thread relief on my case is different. Did you find any interference?

Comment and question: thanks for posting the nice clear pictures of your alternator installation. I now know where the safety wire holes can be drilled, so thanks!

I was just fitting mine a couple of days ago and found that the two 05-06 bolts that thread into the case and starter respectively needed additional washers to avoid interference with the case threads. I see yours only have one washer. I have the Vans supplied IO360 and threaded them up by hand only to find they would not thread down snug. The grip length on the bolts is greater than the thickness of the arms+washer. Maybe the thread relief on my case is different. Did you find any interference?

Thanks Bill.

I just drilled the safety wire holes where they were convienent. I cleaned out almost every threaded (baffle screws/CHT probe) hole on my engine case carefully with a tap. I did this when I was working on the baffles and found the screws bottomed out before they were tight. My engine was overhauled and I think some gunk gets crammed in the holes over time. Being a new engine I'm not sure, but the bolts from plane master worked fine on my engine after cleaning out the threads. Probably good to double check with your engine supplier (vans?) about the bolts just to make sure.Good luck!

I just drilled the safety wire holes where they were convienent. I cleaned out almost every threaded (baffle screws/CHT probe) hole on my engine case carefully with a tap. I did this when I was working on the baffles and found the screws bottomed out before they were tight. My engine was overhauled and I think some gunk gets crammed in the holes over time. Being a new engine I'm not sure, but the bolts from plane master worked fine on my engine after cleaning out the threads. Probably good to double check with your engine supplier (vans?) about the bolts just to make sure.Good luck!

Last edited:

TKATC, I found it after I had already countersunk the hole on the alt air door. Easy enough to redo later but I went with what I had on hand, a countersunk screw/washers/metal locknuts.

I bought the rodend bearing with the stud to use in place of the bugnut for the carb heat but the threads on the rodend are steeper than the standard 10/32. I fashioned the other piece with the angle from some spare parts with the bugnut. Others had posted the bugnut directly on the carb heat arm just wallows out the hole.

Carb heat off.

Carb heat on.

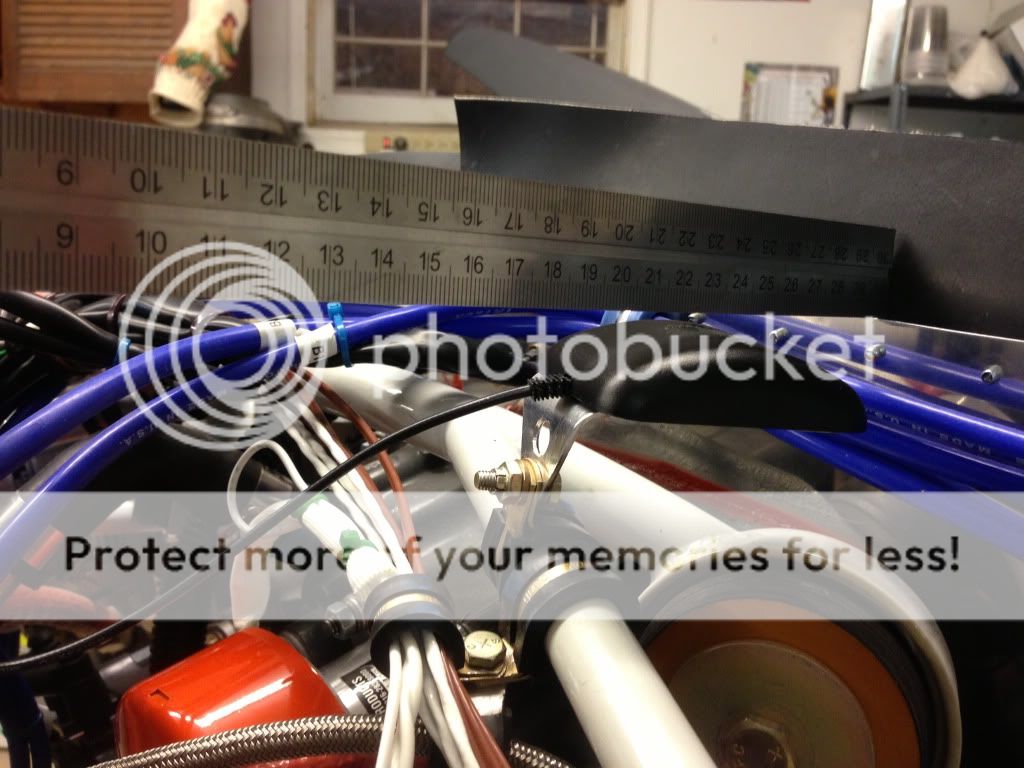

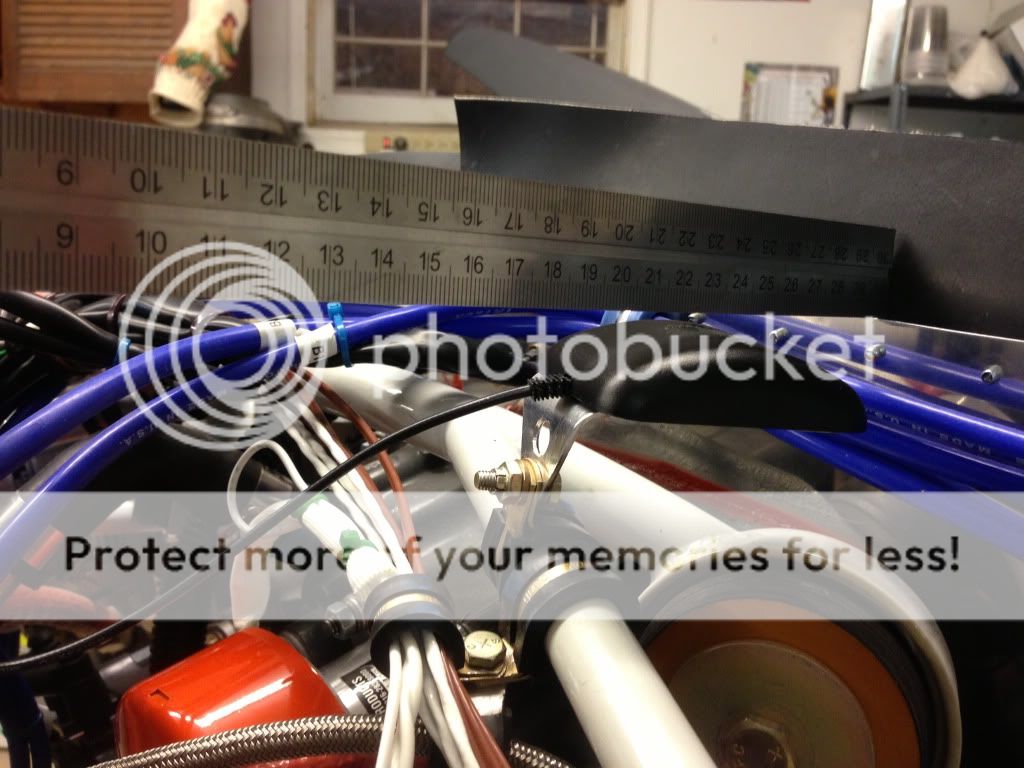

I made a little bracket out of .063 to hold the G3X antenna on the engine mount wirh an adel clamp under the cowling. I set a ruler on top of the firewall to the top of the baffling to simulate the cowling for clearance. I don't think it will get shadowed by the firewall or baffles. Now to make one last firewall passthrough for the antenna cable.

I bought the rodend bearing with the stud to use in place of the bugnut for the carb heat but the threads on the rodend are steeper than the standard 10/32. I fashioned the other piece with the angle from some spare parts with the bugnut. Others had posted the bugnut directly on the carb heat arm just wallows out the hole.

Carb heat off.

Carb heat on.

I made a little bracket out of .063 to hold the G3X antenna on the engine mount wirh an adel clamp under the cowling. I set a ruler on top of the firewall to the top of the baffling to simulate the cowling for clearance. I don't think it will get shadowed by the firewall or baffles. Now to make one last firewall passthrough for the antenna cable.

A little bit of sleep does wonders! I finally made it back to the garage well rested, I took a 2 min look at the control stick wiring and had a solution. I've probably spent 2-3 hours staring at it without any progress.

On the pilot stick I used DB pins to connect the 3 wires and heat shrink to hold it all together.

I ran the grip wires out of the bottom of the stick and back up the stick to the pivot point.

I secured the wires to the stick with silicone tape and zip ties. Securing the wire close to the pivot point seems to work well for wire strain relief and fitting into the wiring run.

The passenger stick utilizes a AMP MateNLock connector so I can remove the copilot stick. I ran the wires on the outside of the lower stick, the stick boot will cover the wires.

On the pilot stick I used DB pins to connect the 3 wires and heat shrink to hold it all together.

I ran the grip wires out of the bottom of the stick and back up the stick to the pivot point.

I secured the wires to the stick with silicone tape and zip ties. Securing the wire close to the pivot point seems to work well for wire strain relief and fitting into the wiring run.

The passenger stick utilizes a AMP MateNLock connector so I can remove the copilot stick. I ran the wires on the outside of the lower stick, the stick boot will cover the wires.

Last edited:

I bought a $12 garden sprayer and some various tubing to make a brake bleeder. The sprayer worked excellent I need to come up with a better sprayer hose to brake bleeder nipple connection and it would be mess free. I used a screw in connection to provide an overflow for the reservoir.

My tech counselor made fun of my cartoonishly large brake line loops so I shortened them up.

I like my new Rigid flaring tool,

1: crimp tubing in tool

2: cut tubing with hacksaw

3: file tubing flat with face of flaring tool

4: deburr tubing

5 : reset the tubing just shy of flush with the flaring tool and make the flare gently with some lube. 1 turn forward 1/2 turn back

My new smaller brake line service loop.

I added an adel clamp to the brake lines at the firewall.

My tech counselor made fun of my cartoonishly large brake line loops so I shortened them up.

I like my new Rigid flaring tool,

1: crimp tubing in tool

2: cut tubing with hacksaw

3: file tubing flat with face of flaring tool

4: deburr tubing

5 : reset the tubing just shy of flush with the flaring tool and make the flare gently with some lube. 1 turn forward 1/2 turn back

My new smaller brake line service loop.

I added an adel clamp to the brake lines at the firewall.

I sealed up the firewall passthroughs and secured the remaining FWF things with Stand offs and zip ties. I also completed the small list of things my tech counselor mentioned. I installed the elevator pushrod, I have enough up elevator but it looks like I need to grind the stop to get enough down elevator. I also connected the cabin heat cable. Come on first flight!

Tom, it's the Rigid RFT 37* from Genuine Aircraft Hardware. Thanks for keeping an eye on me though!

http://www.gen-aircraft-hardware.com/images/pdf/GAHco_Flaring_Stainless_Tubing.pdf

http://www.gen-aircraft-hardware.com/images/pdf/GAHco_Flaring_Stainless_Tubing.pdf

Pressure checking the tanks again with the generic manometer after performing the service bulletin and several years of storage.

I also remade my fuel lines, my first set were 2 piece with questionable flares. Much better result with a decent bender and flaring tools, a little learned patience helps too. (Left side standard pickup)

Ignore those wires, the loose wires are the next thing on the list!

I also remade my fuel lines, my first set were 2 piece with questionable flares. Much better result with a decent bender and flaring tools, a little learned patience helps too. (Left side standard pickup)

Ignore those wires, the loose wires are the next thing on the list!

Both tanks held pressure, yahoo! Kind of a crappy pic but here is the fuel selector.

I'm trying to leave the wings on so I had to use a spring tubing bender for the flop tube side, turned out ok but not as nice as using the real bender. In hind sight I wouldn't have used a flop tube on one side, no need unless I was planning on fully inverted systems.

I made the flap hinge pin retainers.

I drilled the wing root fairings, Hopefully I won't have to pull the wings again to rivet all the nut plates on. I had previously riveted the nut plates on the bottom of the wing skin, why didn't I fit these the first time the wings were on like the plans said. I've spent the past couple weeks completing task that I didn't want to tackle before.

I'm excited for tomorrow, cold compression check is on the "to do" list!

I'm trying to leave the wings on so I had to use a spring tubing bender for the flop tube side, turned out ok but not as nice as using the real bender. In hind sight I wouldn't have used a flop tube on one side, no need unless I was planning on fully inverted systems.

I made the flap hinge pin retainers.

I drilled the wing root fairings, Hopefully I won't have to pull the wings again to rivet all the nut plates on. I had previously riveted the nut plates on the bottom of the wing skin, why didn't I fit these the first time the wings were on like the plans said. I've spent the past couple weeks completing task that I didn't want to tackle before.

I'm excited for tomorrow, cold compression check is on the "to do" list!

Last edited:

Compression check delay for sometime in the next 2 weeks....I spent most of the day inserting and torquing the various wing bolts. I neglected to look at the plans until after I had inserted 8 An-7 bolts, the bottom spar bolts need washers underneath the head of the bolt. I'm assuming the radius of the gusset on the front of the lower spar prevents the washers from laying flat, probably could've ground a side of the washer off but decided to go by the plans (safe bet).

I bolted and safety wired the fuel tank bracket, not torqued but snugged till the washer didn't spin and all pieces pulled together.

The wire for my GTP59 was only 10' long, enough to use existing wiring runs to the first wing rib. I wanted it further out, I drilled the 5/16 hole just aft of the spar one bay in from the bell crank. I'll have to splice/solder some more wire tomorrow.

I bolted and safety wired the fuel tank bracket, not torqued but snugged till the washer didn't spin and all pieces pulled together.

The wire for my GTP59 was only 10' long, enough to use existing wiring runs to the first wing rib. I wanted it further out, I drilled the 5/16 hole just aft of the spar one bay in from the bell crank. I'll have to splice/solder some more wire tomorrow.