fl9500

Active Member

Hi,

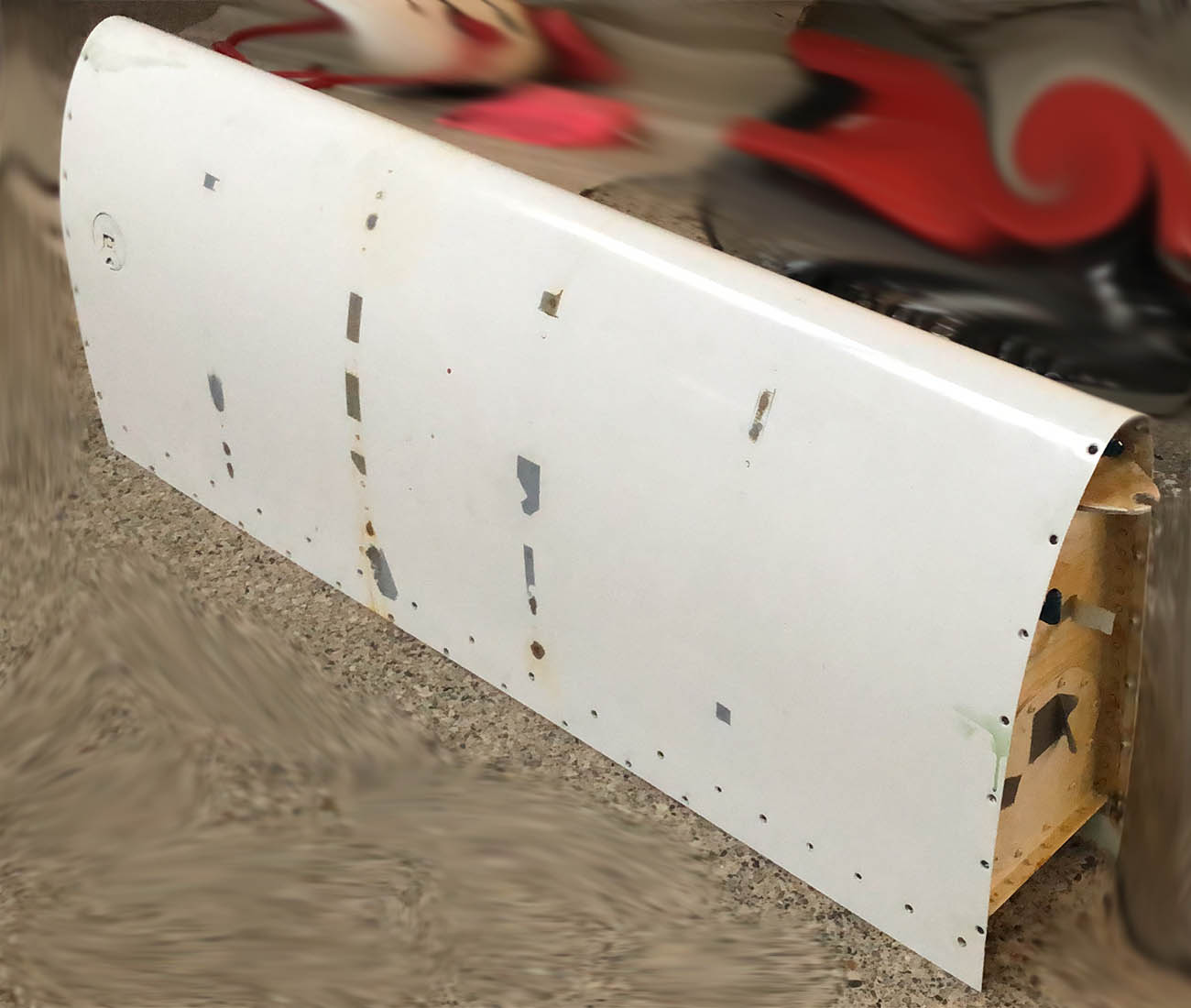

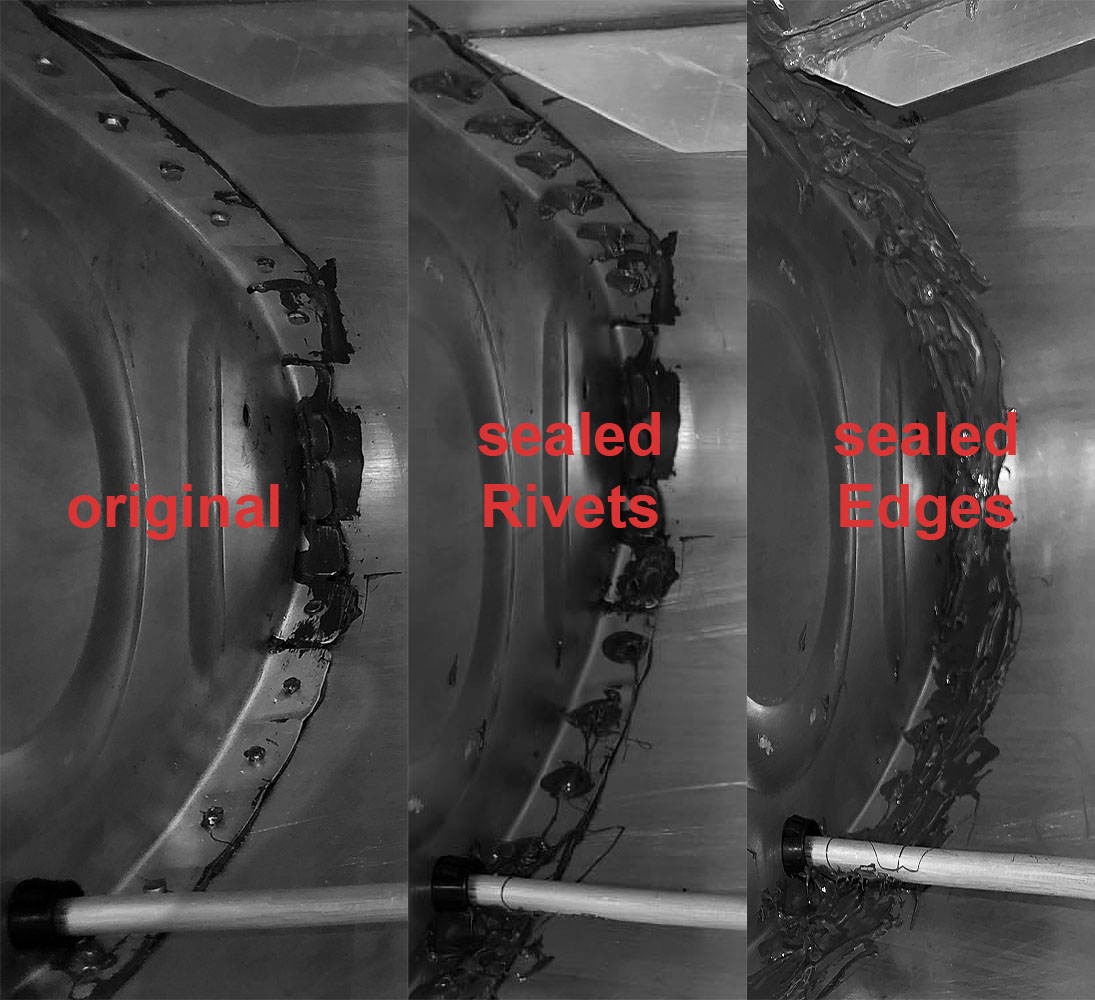

I will try to seal all five chambers of one of my RV6 tanks, which has many leaking rivets. with original VAN's "Fuel tank repair kit".

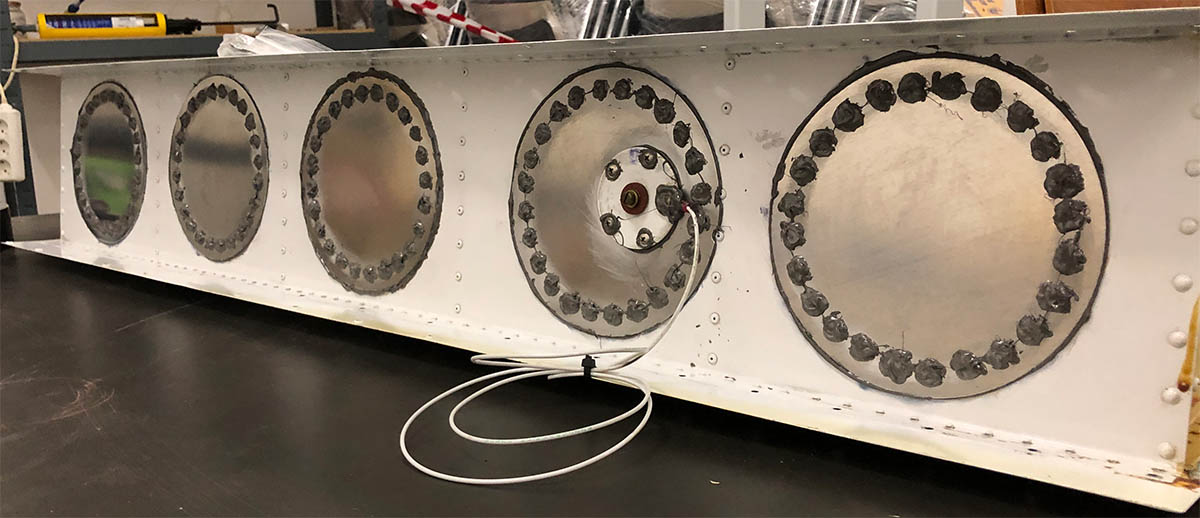

Which is the best saw-type to cut the big holes in the back of the fuel tank ?

What is the best method to reach all seams of the tank with the sealer ?

Thank you for all tips,

Achim

I will try to seal all five chambers of one of my RV6 tanks, which has many leaking rivets. with original VAN's "Fuel tank repair kit".

Which is the best saw-type to cut the big holes in the back of the fuel tank ?

What is the best method to reach all seams of the tank with the sealer ?

Thank you for all tips,

Achim