Regardless those speeds are outstanding

It was extremely windy today at Taylor and the ceilings were overcast at about 3k msl over the airport, lower in some other places. Mike Thompson and I were battling to avoid being last in the RV Blue Class. This time I beat him. He commented that he played the winds wrong but he didn't explain. Weather here is forecast to be severe tomorrow so when I found that the current conditions were modest IMC. I filed and departed without food or the award ceremony. I had a Sausage Biscuit, hash browns in a paper sleeve and black coffee from our local McDonald's on the way to the airport at 5:30 this morning and I still haven't eaten anything else. Sounds like the Taylor organizers put out a good spread - I miss that ... Well I'm home and I had a couple more hours of sleep where I can relax then get back to work on this fairing for the race next Saturday at Llano, TX. These RV-8 guys are eating our lunch and I can't have that (they are fine folks actually but this is racing!). The new LASAR mag worked great and I have to do something for the folks at Aircraft Spruce and Champion for getting it in my hands in time to install it, time it, test it and make the race. I mean, on Thursday they hear the words airplane on the ground for a bad mag that they did not have in stock and it was registered to race on Saturday over 400 miles away... Most people would have said just scratch but they jumped on it like they were part of my team. They said if there was one to be found they would find it and get it in my hands the next day (Friday) AND THEY DID!

I got it at around 11 am Friday and I had trouble with everything I had to do to get the work done. I was already tired from all the late hours on the outlet fairing work so my efficiency was at the plodder level - just put one foot in front of the other and keep progressing it's only mechanical - it has a solution. One example, I had to get the drive gear off of the old mag's coned and keyed shaft. I tried with everything I had without success then I went to the nearby auto parts store and bought a little wheel puller. It was pitifully inadequate for the task. After at least two hours of effort and trips I went to SkyVenture's Maintenance department at Drake field and this mechanic that I didn't really recognize but had helped me once before said hi Mr. Axsom how is your wife doing - after I stopped crying I explained my problem with the gear on the mag shaft. He said they can be tough and said I hope you won't think less of me for this - and he pulled out a blow torch and a crowbar and had it off in seconds. It went on like that all day. I had this fear that as I was putting everything back together (including the custom baffling in the lower cowl) that the final blow would be a dead battery or that the problem was not the mag at all but the controller. At just a few minutes after midnight when the final screw was installed I climbed in and it fired off right away and the mag check was good.

At this point I was ready to just go to bed but how do you turn your back on the efforts of so many good people that helped you get there? I got to bed at around 2 am and slept til 4:15 then got up and cleaned up to make the trip. I hadn't shaved or bathed for days and barely brushed my teeth - I couldn't present myself that way as a racer in Taylor.

I refueled the plane before going home for the sleep so all I had to do was get a briefing, file an IFR flight plan, pull the plane out, get in the cockpit and take the checklist up to "ignition" and wait for some glimmer of sunlight since I have no lights in race configuration. When I got on my way the headwinds were between 50 and 60 knots but I knew the ceilings were too low for racing at Taylor so I had a shot at making it in time to race. I did and the rest is history.

On to Llano, TX for the Hill Country Air Race next Saturday - see you there.

Bob Axsom

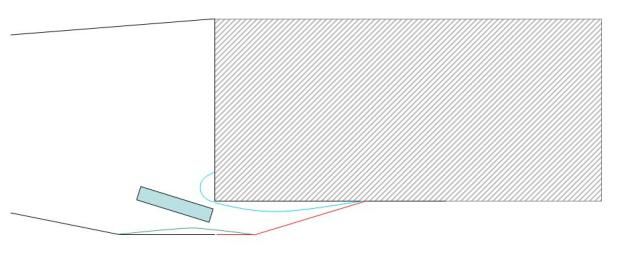

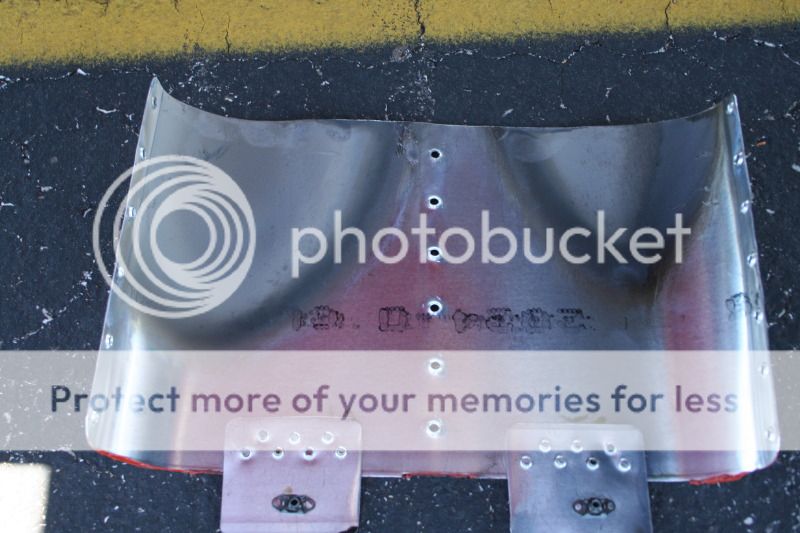

It was extremely windy today at Taylor and the ceilings were overcast at about 3k msl over the airport, lower in some other places. Mike Thompson and I were battling to avoid being last in the RV Blue Class. This time I beat him. He commented that he played the winds wrong but he didn't explain. Weather here is forecast to be severe tomorrow so when I found that the current conditions were modest IMC. I filed and departed without food or the award ceremony. I had a Sausage Biscuit, hash browns in a paper sleeve and black coffee from our local McDonald's on the way to the airport at 5:30 this morning and I still haven't eaten anything else. Sounds like the Taylor organizers put out a good spread - I miss that ... Well I'm home and I had a couple more hours of sleep where I can relax then get back to work on this fairing for the race next Saturday at Llano, TX. These RV-8 guys are eating our lunch and I can't have that (they are fine folks actually but this is racing!). The new LASAR mag worked great and I have to do something for the folks at Aircraft Spruce and Champion for getting it in my hands in time to install it, time it, test it and make the race. I mean, on Thursday they hear the words airplane on the ground for a bad mag that they did not have in stock and it was registered to race on Saturday over 400 miles away... Most people would have said just scratch but they jumped on it like they were part of my team. They said if there was one to be found they would find it and get it in my hands the next day (Friday) AND THEY DID!

I got it at around 11 am Friday and I had trouble with everything I had to do to get the work done. I was already tired from all the late hours on the outlet fairing work so my efficiency was at the plodder level - just put one foot in front of the other and keep progressing it's only mechanical - it has a solution. One example, I had to get the drive gear off of the old mag's coned and keyed shaft. I tried with everything I had without success then I went to the nearby auto parts store and bought a little wheel puller. It was pitifully inadequate for the task. After at least two hours of effort and trips I went to SkyVenture's Maintenance department at Drake field and this mechanic that I didn't really recognize but had helped me once before said hi Mr. Axsom how is your wife doing - after I stopped crying I explained my problem with the gear on the mag shaft. He said they can be tough and said I hope you won't think less of me for this - and he pulled out a blow torch and a crowbar and had it off in seconds. It went on like that all day. I had this fear that as I was putting everything back together (including the custom baffling in the lower cowl) that the final blow would be a dead battery or that the problem was not the mag at all but the controller. At just a few minutes after midnight when the final screw was installed I climbed in and it fired off right away and the mag check was good.

At this point I was ready to just go to bed but how do you turn your back on the efforts of so many good people that helped you get there? I got to bed at around 2 am and slept til 4:15 then got up and cleaned up to make the trip. I hadn't shaved or bathed for days and barely brushed my teeth - I couldn't present myself that way as a racer in Taylor.

I refueled the plane before going home for the sleep so all I had to do was get a briefing, file an IFR flight plan, pull the plane out, get in the cockpit and take the checklist up to "ignition" and wait for some glimmer of sunlight since I have no lights in race configuration. When I got on my way the headwinds were between 50 and 60 knots but I knew the ceilings were too low for racing at Taylor so I had a shot at making it in time to race. I did and the rest is history.

On to Llano, TX for the Hill Country Air Race next Saturday - see you there.

Bob Axsom

Last edited: