So I can’t find any thoughts on an open oil filler cap to let engine moisture escape from a hot engine ??

So after a nice one hour plus flight today , after a fresh oil change, on a 300 hour well maintained engine (oil temp running at 185F). I pulled the aircraft is back in hanger .. I pulled the dip stick and again saw the milky white oily mixture on the filler cap / filler neck (clearly water in the oil) and watch the vapors pour out..

I’m sure it was a mixture of mostly water and maybe some hydrocarbons.. I then watched as the water continued to condense on a good sized and cold (35F) chunk of aluminum I held over the open oil filler neck. I mean a ¼- ½ teaspoon over a 10-15 minute period. (yes engine breather tube clear)

With the oil filler cap left on.. There is no way that ½ teaspoon of water is ever going to get out of the engine .. A 2’ long 3/8ID crankcase vent tube.. that’s open ONLY BELOW the engine.. sure is not going to let the moisture escape..

It really made it clear why these aircraft engines rust for the inside out.. A sealed up engine has no chance for a reasonable life unless its flown A LOT.

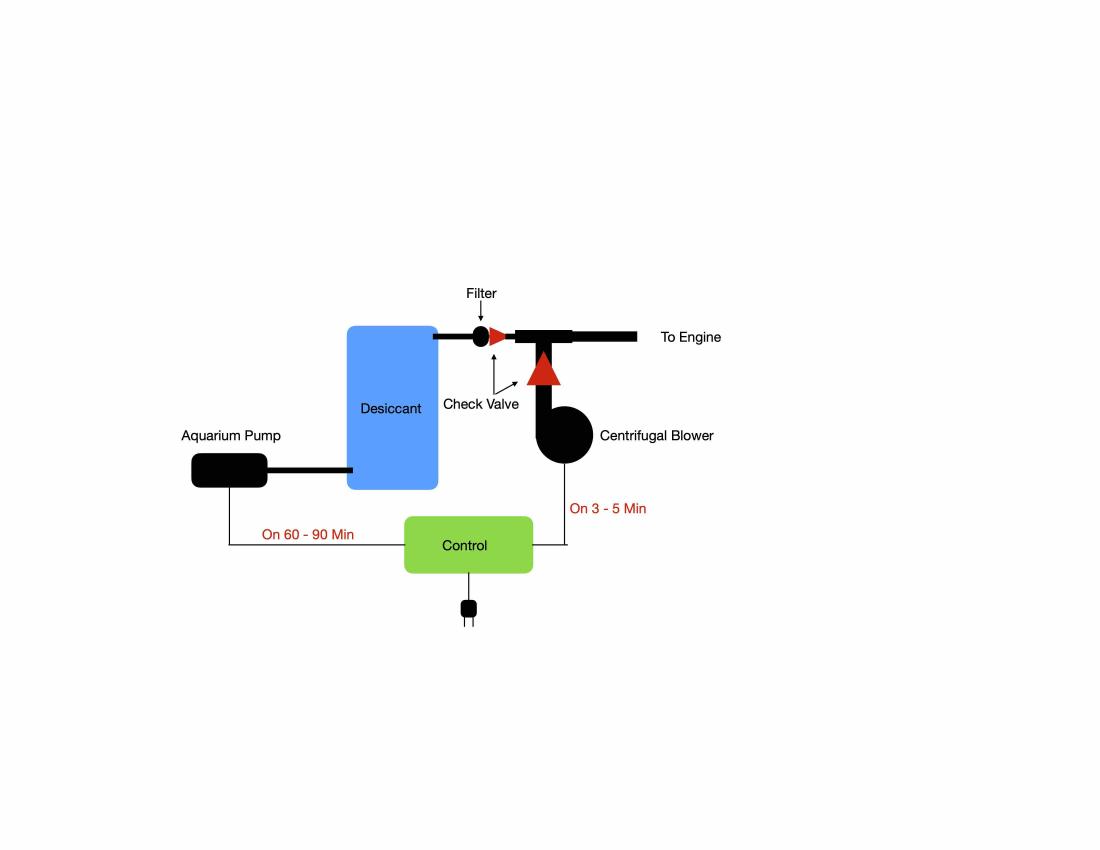

So can it be as simple as leaving the oil filler cap off for a few hours... to a day.. Letting the moisture “Vent out of the TOP of the engine... ? Enhancing the moisture dissipation by leaving the engine heater on for a few hours ( Cylinder & oil pan heaters) Yes.. There is no way you would want to leave an engine heater on with a “Sealed-Up” engine.. The moisture just able to circulate inside the crank case. Rust.. Rust ..Rust...

So there is a nice $49 monitor module (amazon) that will record temp/humidly every minute for up to 20 days and then be downloadable to a smart phone or Excel .. With a slight mod.. and remote wiring of the sensor, so I can have the sensor in the crankcase after a flight.. I’m going to get some real data on this idea ..

Anyone else looked into the simple moisture venting concept?

Experiment #1

Nice flight.. Let cool over night ..

Next day.. Measure internal engine humidity for several days

Experiment #2

Nice flight.. Leave oil cap off.. With engine heat for 6 Hours.. Heat off.. Cap off..

Next day(1) .. Replace oil cap.

Next day(2) ..Measure internal engine humidity for several days

Give me a 2 weeks and I will have some real data

AL

So after a nice one hour plus flight today , after a fresh oil change, on a 300 hour well maintained engine (oil temp running at 185F). I pulled the aircraft is back in hanger .. I pulled the dip stick and again saw the milky white oily mixture on the filler cap / filler neck (clearly water in the oil) and watch the vapors pour out..

I’m sure it was a mixture of mostly water and maybe some hydrocarbons.. I then watched as the water continued to condense on a good sized and cold (35F) chunk of aluminum I held over the open oil filler neck. I mean a ¼- ½ teaspoon over a 10-15 minute period. (yes engine breather tube clear)

With the oil filler cap left on.. There is no way that ½ teaspoon of water is ever going to get out of the engine .. A 2’ long 3/8ID crankcase vent tube.. that’s open ONLY BELOW the engine.. sure is not going to let the moisture escape..

It really made it clear why these aircraft engines rust for the inside out.. A sealed up engine has no chance for a reasonable life unless its flown A LOT.

So can it be as simple as leaving the oil filler cap off for a few hours... to a day.. Letting the moisture “Vent out of the TOP of the engine... ? Enhancing the moisture dissipation by leaving the engine heater on for a few hours ( Cylinder & oil pan heaters) Yes.. There is no way you would want to leave an engine heater on with a “Sealed-Up” engine.. The moisture just able to circulate inside the crank case. Rust.. Rust ..Rust...

So there is a nice $49 monitor module (amazon) that will record temp/humidly every minute for up to 20 days and then be downloadable to a smart phone or Excel .. With a slight mod.. and remote wiring of the sensor, so I can have the sensor in the crankcase after a flight.. I’m going to get some real data on this idea ..

Anyone else looked into the simple moisture venting concept?

Experiment #1

Nice flight.. Let cool over night ..

Next day.. Measure internal engine humidity for several days

Experiment #2

Nice flight.. Leave oil cap off.. With engine heat for 6 Hours.. Heat off.. Cap off..

Next day(1) .. Replace oil cap.

Next day(2) ..Measure internal engine humidity for several days

Give me a 2 weeks and I will have some real data

AL

Last edited: