Bill Boyd

Well Known Member

Scott is correct

... no surprise there. But the plans not only mention deformation by clecos, but the need to fill in all but the remaining round portion of the keyhole created by the round file. And he brings up a point I want to pick his brains on:

The bracketing of the bracket by the flox no doubt lessens the shear load on the screws when taxiing over bumps (for which Hop-Along Aerodrome is aptly named). But there is this caveat in the plans:

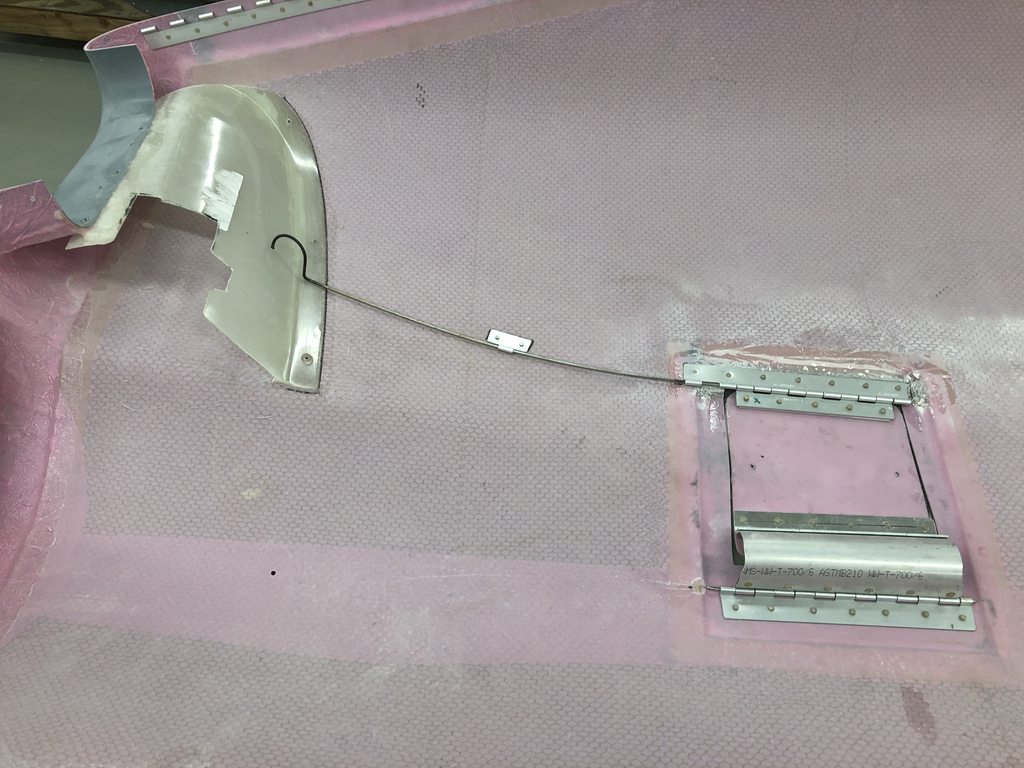

"If the epoxy/flox is allowed to engulf the edges of the bracket the fairings will be difficult to remove. Prevent this by using clay or shims to add thickness to the outboard side of the bracket especially near the edges."

I can imagine it would make it difficult to get the pants free of the bracket after this stuff sets up. Is it a question of how much "engulfing" goes on? It seems like any is going to make it difficult to pull the pants back off, but maybe I'm overthinking the difficulty, given how flexible the pieces are.

... no surprise there. But the plans not only mention deformation by clecos, but the need to fill in all but the remaining round portion of the keyhole created by the round file. And he brings up a point I want to pick his brains on:

The bracketing of the bracket by the flox no doubt lessens the shear load on the screws when taxiing over bumps (for which Hop-Along Aerodrome is aptly named). But there is this caveat in the plans:

"If the epoxy/flox is allowed to engulf the edges of the bracket the fairings will be difficult to remove. Prevent this by using clay or shims to add thickness to the outboard side of the bracket especially near the edges."

I can imagine it would make it difficult to get the pants free of the bracket after this stuff sets up. Is it a question of how much "engulfing" goes on? It seems like any is going to make it difficult to pull the pants back off, but maybe I'm overthinking the difficulty, given how flexible the pieces are.