CubedRoot

Well Known Member

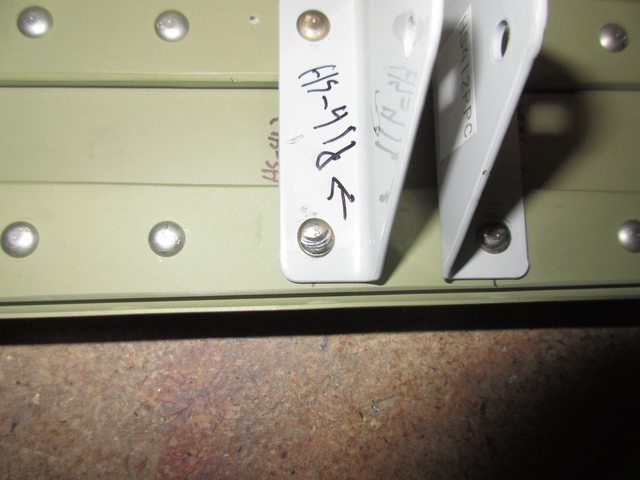

So I riveted my first actual structure of tail kit tonight, and things went pretty good, save for one rivet I am questioning.

I was riveting the HS-412PP to the rear spar assembly, and my squeezer must have been offset or something, and I ended up slightly denting the top of the manufactured head of the rivet:

I haven't drilled it out yet, so I figured I would ask the collective knowledge here on the forums if I should or not.

Should I attempt to drill this sucker out and replace it? Its a AN470AD4-7 rivet, and I don't have any "oops rivets" yet. I am semi-confident I could drill it out without enlarging the hole, but if there is no need to, I will leave it.

Here is a link to the full size photo for better resolution of the rivet:

https://lh3.googleusercontent.com/W...ZaB6cff5kzHk7Z_VRPjBlQSJocp1IQ=w2532-h1898-no

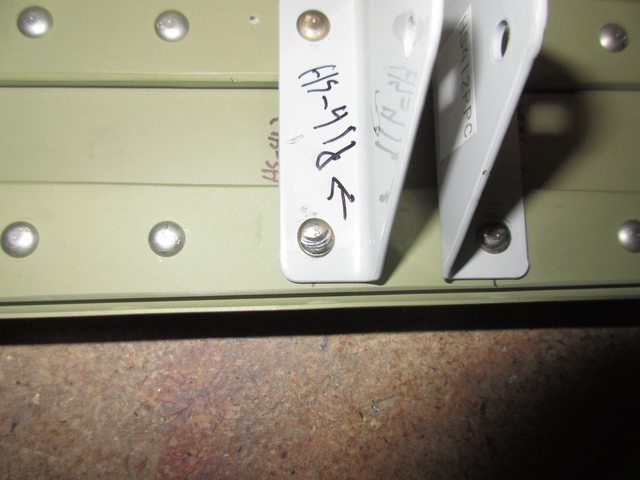

I was riveting the HS-412PP to the rear spar assembly, and my squeezer must have been offset or something, and I ended up slightly denting the top of the manufactured head of the rivet:

I haven't drilled it out yet, so I figured I would ask the collective knowledge here on the forums if I should or not.

Should I attempt to drill this sucker out and replace it? Its a AN470AD4-7 rivet, and I don't have any "oops rivets" yet. I am semi-confident I could drill it out without enlarging the hole, but if there is no need to, I will leave it.

Here is a link to the full size photo for better resolution of the rivet:

https://lh3.googleusercontent.com/W...ZaB6cff5kzHk7Z_VRPjBlQSJocp1IQ=w2532-h1898-no