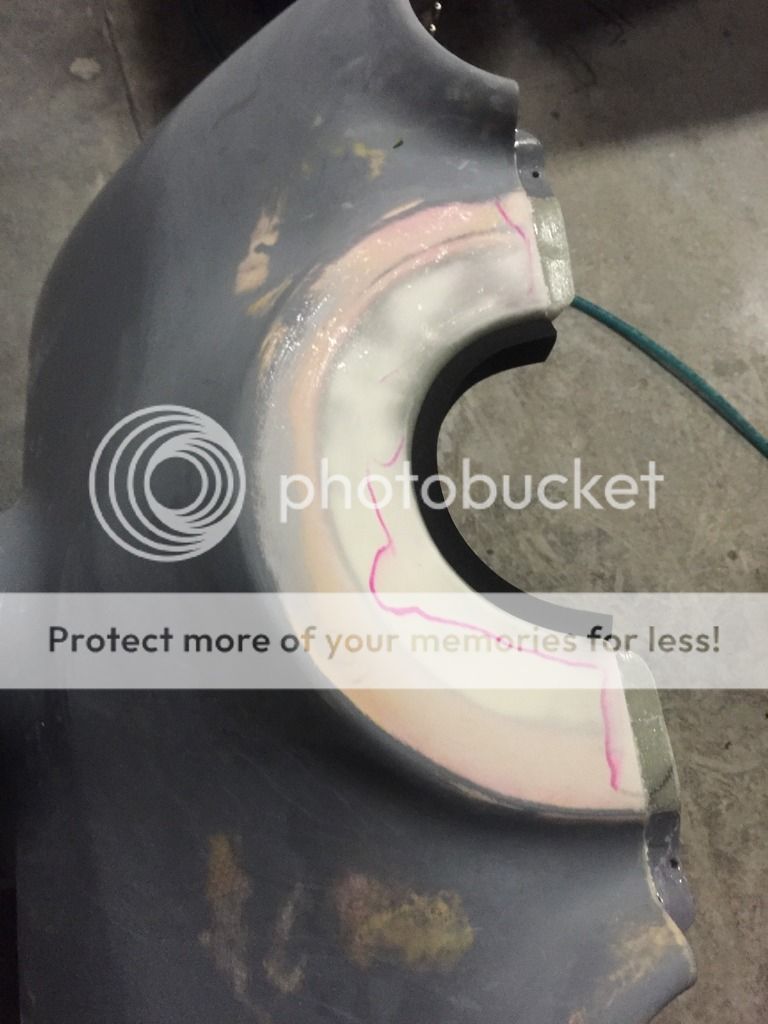

I had to remove 1/2 inch from the front of my plug to utilize it as a 1 piece layup, I added the center plastic from my previous mold to the cut-off plug.

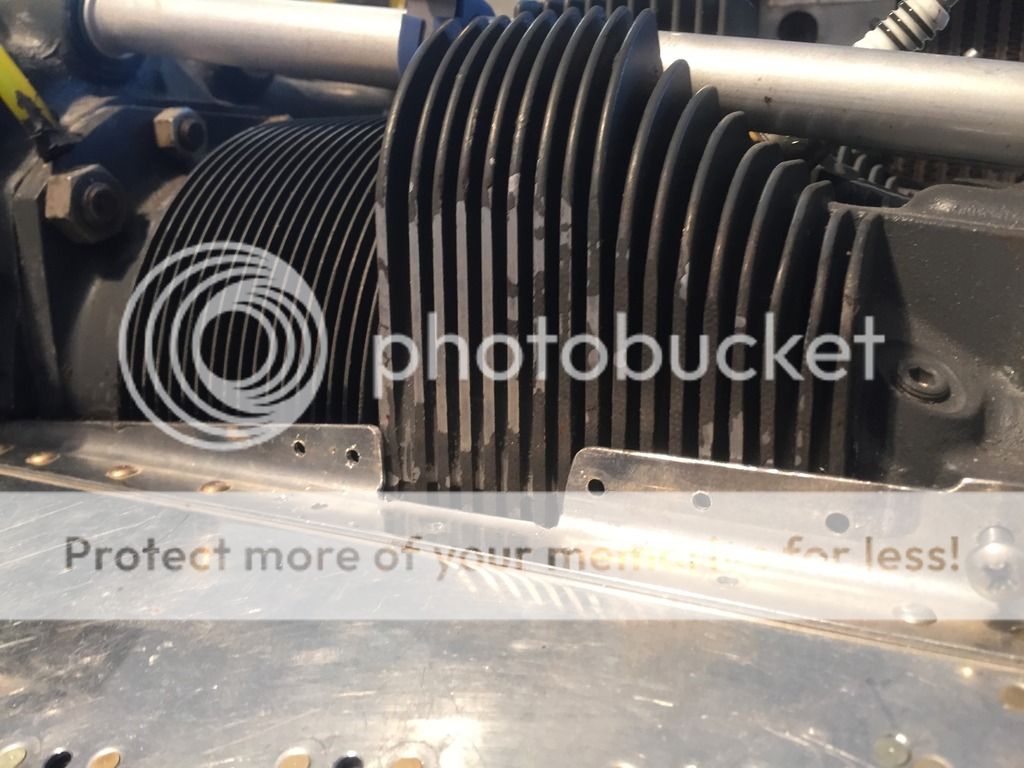

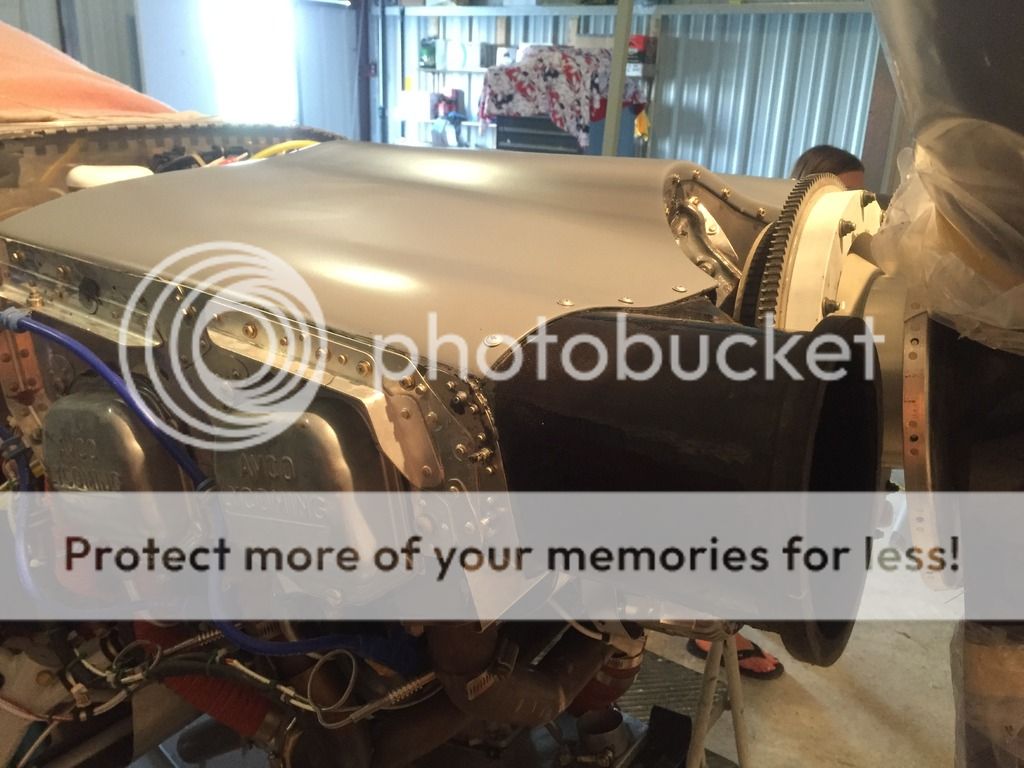

I re-faired it/epoxy coated it/sanded it/painted it, much easier and nicer the second time. I laid the fiberglass on the plug and trimmed it to shape.

I didnt get any pics of the intake boot layup, much like before 3 layers of rubber followed by fabric impregnated with rubber and a final layer of rubber. I did not add any reinforcement to the front ring this time, it is just rubber. I did add an extra layer of fabric about 1.5 inches wide On the back of the inlet ring to the boot, I wouldn't add the extra fabric again as it was hard to get it to lay right and was bumpy.

As part of my annual I also addressed the slop in my tailwheel and tailwheel spring. I added taper pins to my tailwheel yoke but found I still had a little bit of slop in the tail wheel spring to bulkhead mount as well. I used a B&S #2 taper pin reamer and a AN386-2-14 taper pin, the taper pin was way longer than needed but figured I could cut off the excess. I made this "jig" from scrap wood to hold the tail wheel fork perpendicular to the longitudinal axis of the airplane, I figured a large square of 3/4" plywood on a flat hangar floor with a 2x6 and spacers of plywood at 90* wood (pun intended) do the trick.

The jig worked well to hold the tail wheel yoke at the correct angle, but with the hole reamed to the correct depth for the taper pin left some hole slop to the left of the taper pin.

Reaming out the slop in the top of the hole ended up using the entire length of the An386-2-14 taper pin with lots of length protruding up. I tapered the inside diameter of some stock to make a large washer until I can order an AN-386-3 taper pin. It sure is messy and oily in the back!

The tail wheel is solid and straight now with no slop.