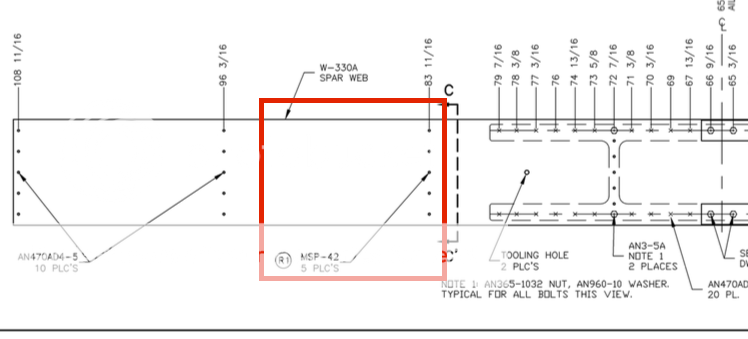

Earlier, I'd decided to use 1" x 1" x 1/8" upper longerons instead of 3/4" x 3/4" x 1/8" just to get a bit more edge distance in a couple places. But since I didn't want to carry close to a pound of extra weight around, I needed to remove the excess width in the rest of the longerons. Here's the overall plan for the shape that I wanted to end up with.

Cut plan

I asked around and one friend had successfully done this job on his non-RV with his bandsaw, and offered to help me. I tried to do it on my bandsaw with some scrap and that didn't go so well; his blade guides are superior to mine. A couple guys suggested using a router but I didn't know how to set that sort of affair up. Plus, after I'd built my kitchen cabinets and turned the shop into an RV factory, I'd gotten rid of my handy general-purpose router table. The final suggestion was to have it machined by a machinist for big bucks. I tried to get a quote from a local water-jet company but they didn't bid on it. Their informal estimate was comparable to the machinist's.

So I started thinking.

After gathering some things that were laying around the shop or in my basement, I constructed this router table. Previously, I'd bemoaned that I no longer had the router table with which I built my kitchen but this turned out to be a good thing; that was a general-purpose tool and I made this one specifically for this, and it's better.

Longeron Routing Tool

The plastic guides use UHMW which gave the right feel; I push the angles through by hand. The aluminum bar is a 1" x 2" tube and it would have been better to use 2" x 2" but no complaints - this worked pretty darn well. The bar is adjustable by changing the clamping position at the right end, and the leverage gives slightly more than a 3:1 mechanical advantage; it's not a vernier but it's close enough.

The design both closely guides the angles and supports them on the non-cut flange, while allowing some movement up and down. But not much, since one of the legs of the plastic blocks prevent most movement there. The fixture also lets the cutter get readjusted axially without changing any cutting position if that's needed due to wear. And while it was still cutting well, I thought I saw some wear after three of the four sides was cut and moved the bit to a fresh position.

The router table now has a few pieces of UHMW chafe tape which served two purposes - it let the angles slide smoothly and it kept them slightly above the table so that the chips didn't cause binding.

My bit is a 1/2" or 3/8" steel (that is, not carbide) spiral bit. It's

this bit. The spiral deflects some of the chips into the router instead of away from the router. The router is mounted underneath with the bit upward and the chips don't fly up, which is good. The bit, by the way, is holding up better than I thought it would. It cost less than $30. The router is an adjustable-speed Dewalt, running about 18,000 rpm.

I needed something that would let me adjust the depth of the cut before hitting the aluminum and those divots did the trick. Yes, they completely used up one 2" very coarse sanding drum - it was worth it. I did both longerons at the same time, clamped together. First I used an electric drill. It got very hot. Then I used a Sioux air drill. It got very cold. Physics in action. Then I brought out my industrial Ingersol-Rand air drill and it just chugged through the job. A friend of mine used to say "Don't force it, Dave, get a bigger hammer." And for this job, this was it. Of course the air compressor got a real workout.

Longeron Divot

The router chips fly all over the shop. I'll spend next week cleaning up. I'm using a couple of small pieces of 4x4 near the router as simple chip deflectors and that keeps hot chips off my wrists and avoids some of the mess. When I first started, I found immediately that I needed to wear a long-sleeve shirt.

I tried two lubricants. One of our local RV group recommended WD-40 and that was the first one I tried. It turned out to be hard to apply without a lot of overspray, even using the tube, and made a considerable mess. With this lubricant I could cut a width of about .070 inches. Then I tried Boelube liquid, which is easy to apply, leaving little mess, and permits cuts up to at least .125 inches. It does smoke, though, which the WD-40 didn't. I regard Boelube as far superior to the WD-40. I am not a WD-40 fan.

The longerons are long enough that I needed to keep the garage door open to rip these. Something to consider.

I had a couple of those adjustable rollers that you can use to support long pieces being ripped. They worked. Handy things.

The finish isn't all that great.I'd say it's something around a 125 micro inch finish but it's been so long since I've worked with a comparator my eyes just aren't calibrated any more. I'll have to smooth the edges. The edges also picked up a burr, and a few swipes with a file took care of those. I was aiming at .750 or more and with the rough finish, I stopped at about .010 or .020 extra. It'll give me some allowance for smoothing.

Router Cut

Now that the routing's finished, I've still got to smooth the edges, but at least I know how to do that.

It's good to be back to work on the RV-3B. The last quarter was difficult to get to work on it. One of the things that I did was make this glove box, from scratch, for a friend who's re-doing the panel on his non-RV. Seeing that has convinced me not to put a new panel in my Cessna 180. On the plus side, he gave me his excess aluminum, so I got some .025 and .040 sheet, plus some 3/4 x 3/4 x 1/16 angle and a stick of Van's .025 bent angle. These things are always handy.

Glove Box

Alternate photo hosting is

here,

here,

here,

here,

and here.

Dave