Can't help but wonder, is a plenum better than standard baffle system?

It's about sealing. Sealing relates to two issues, cooling and drag, which although related, are not quite the same thing.

Cooling mass is forced through the cylinder fins and oil cooler by the difference in pressure between the upper and lower cowl volumes. Given the typical large exit, leakage past baffle seals lowers that differential pressure, resulting in less mass flow, thus less cooling. The brain-dead "fix" is to increase exit size rather than fix the leakage.

Why brain dead? Because although it may fix the cooling problem, any additional air passing through the cowl which doesn't pass through a heat exchanger is just pure drag. The old Mississippi State NASA reports showed that typical GA flap baffles allow

a lot of leakage. The typical GA installation works with crappy baffling because the cowls generally have

huge inlets and exits proportional to the HP cooled. They are also very draggy. Our RV cowls have inlet and exit sizes which don't offer much margin for bad sealing.

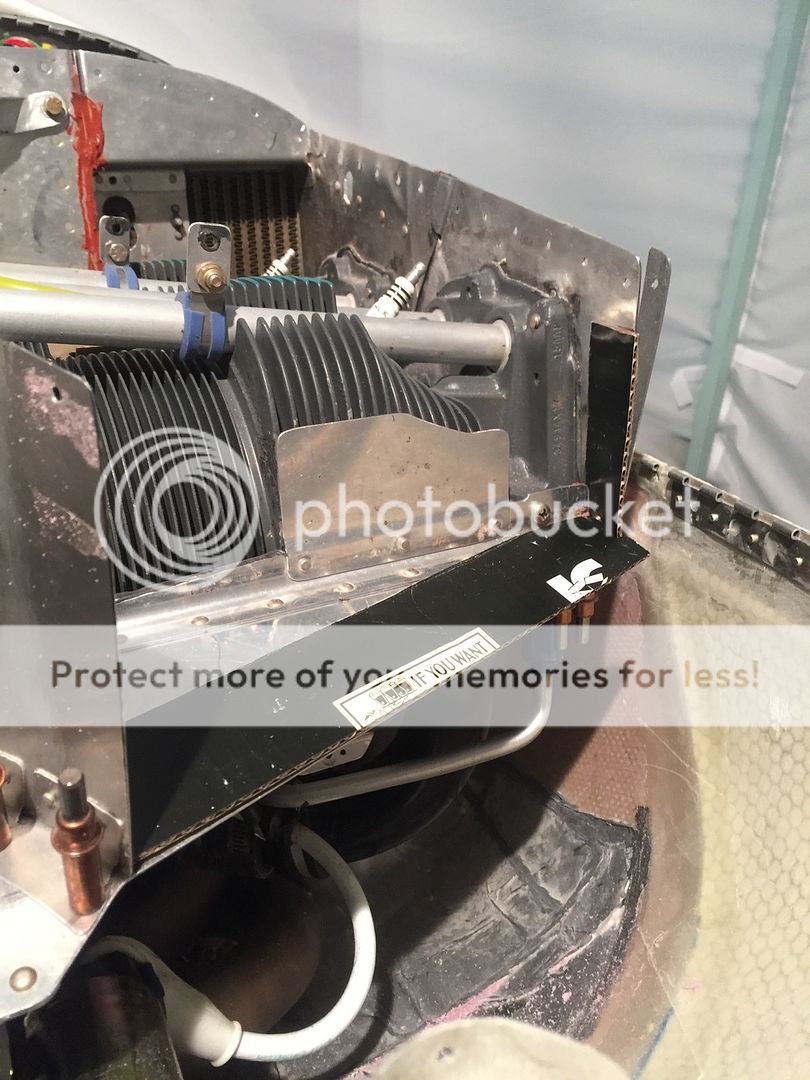

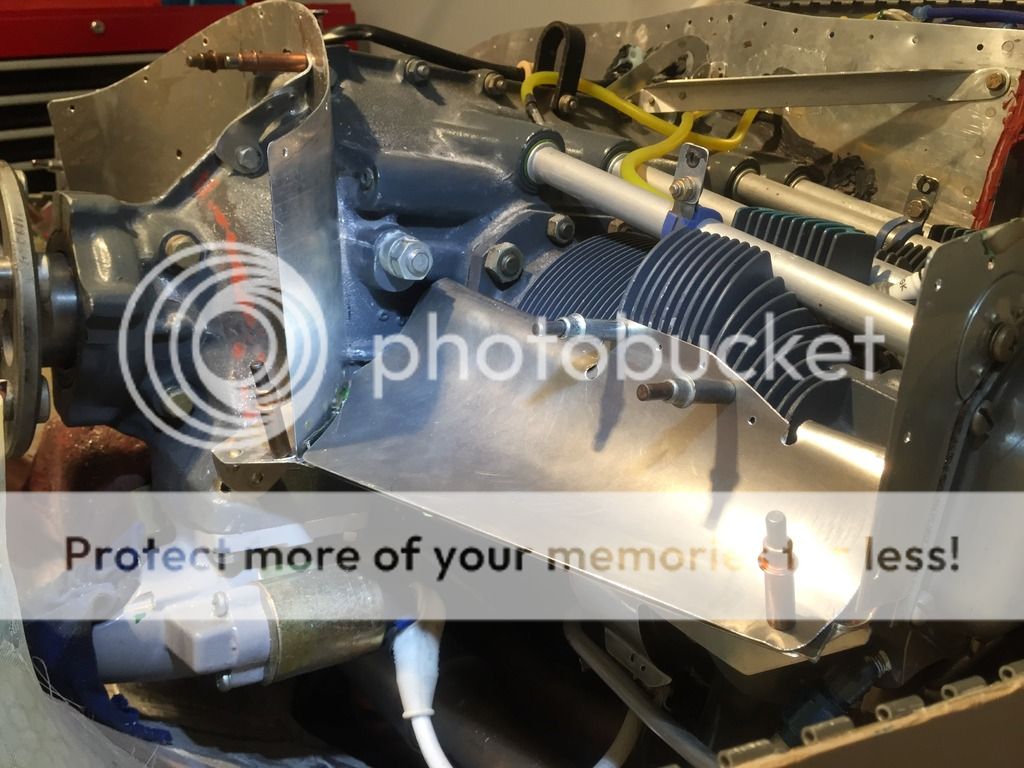

I can pretty much guarantee the system you see above has less than 1% leakage, and I'll stop those leaks when I see them. The goal is to pass less air through the cowl and heat it more, while maintaining residual pressure in the lower cowl volume in order to increase exit velocity.

BTW, measurement says the big round inlets are not a

lot better than standard RV-8 inlets at converting dynamic pressure to increased static pressure. However, the leakage rate is far lower than standard flap baffles.

A plenum

with a bad inlet is going to perform worse than standard inlet in terms of pressure recovery. IMHO, there are quite a few plenum installations with crappy inlets. The automatic advantage to a large, low velocity inlet is that it is hard to do it badly; they are tolerant of error. Look close at some recent GA designs with low Vi/Vo inlets. They work fine with no diffusers inside the inlets...zip.

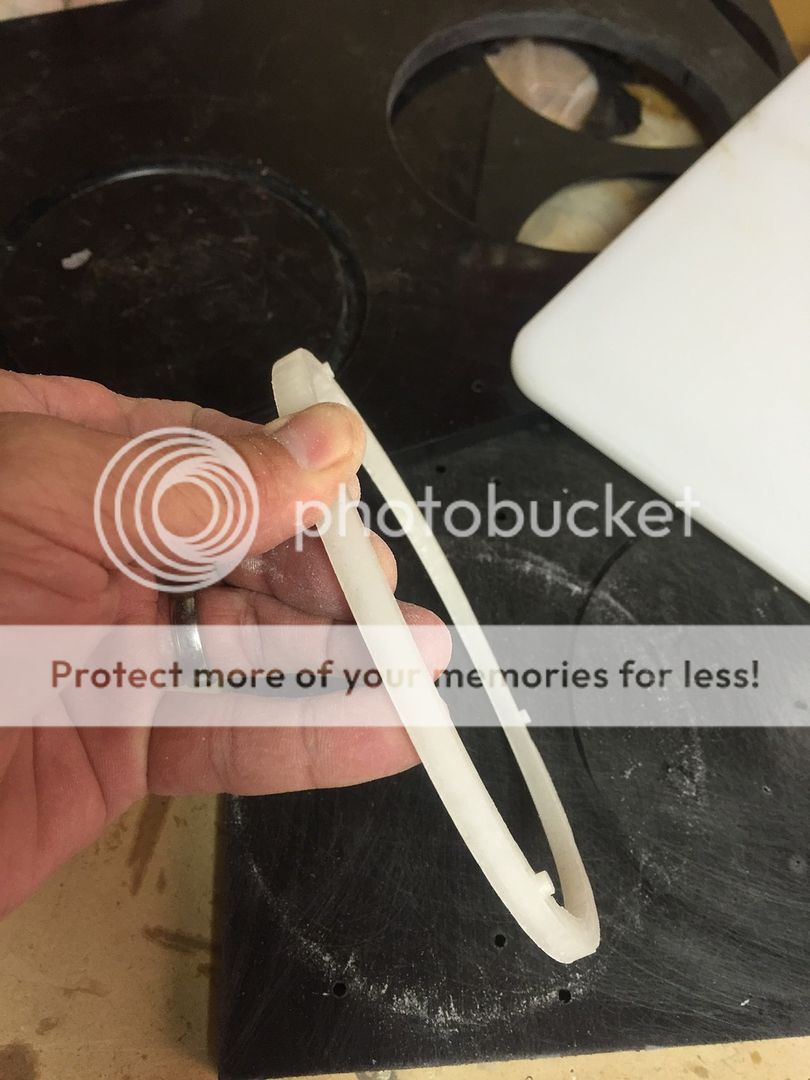

Which brings us to a logical question; why one-piece rubber ducts rather than the common hard fiberglass snout with a tubular flex connector? First, with high engine torque (meaning at low airspeed, just when max cooling is needed) most of them are misaligned; the end of the snout doesn't line up with the inlet ring. The result is a huge lip inside the inlet, which trips flow. If inlet velocity is low (the tolerant low Vi/Vo inlet), it won't make a huge difference. If velocity is high (a small ring, high Vi/Vo inlet with an internal diffuser), tripping the flow hurts pressure recovery.

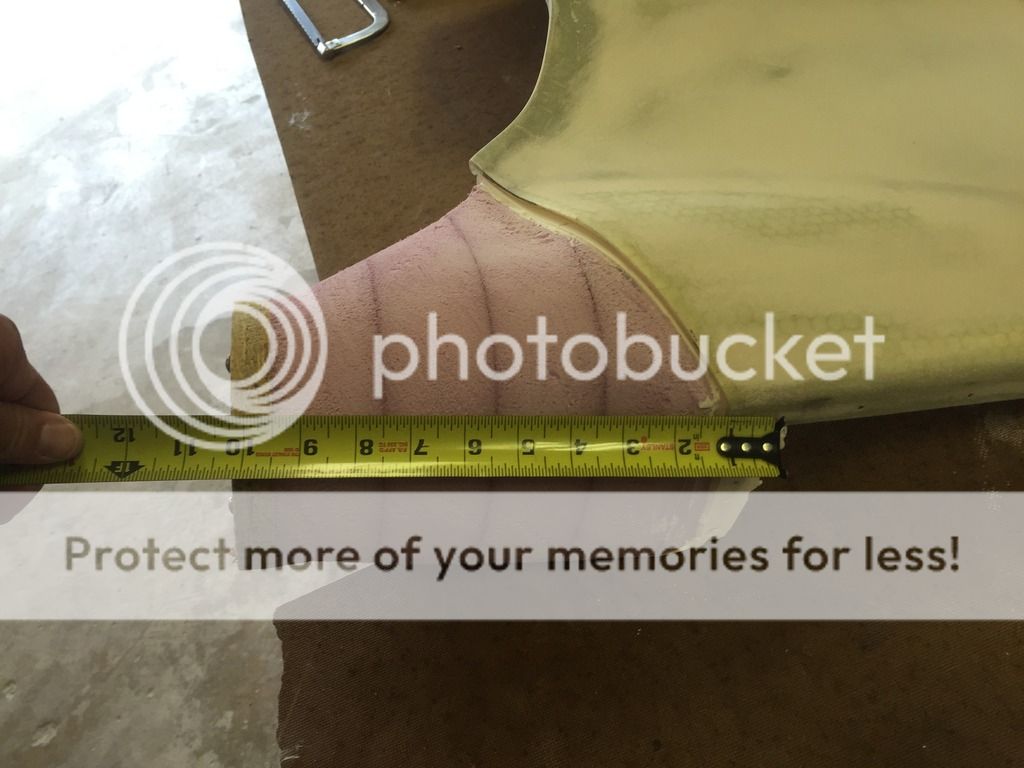

Second, in my own application (RV8, big motor, metal CS prop), I did not want a prop extension, as it would have created a CG problem. So, the inlet ducts needed to be

short. A low velocity inlet doesn't need length for internal diffusion...and the rubber duct doesn't need length for the straight sections required for clamping a flex coupling to a hard duct.

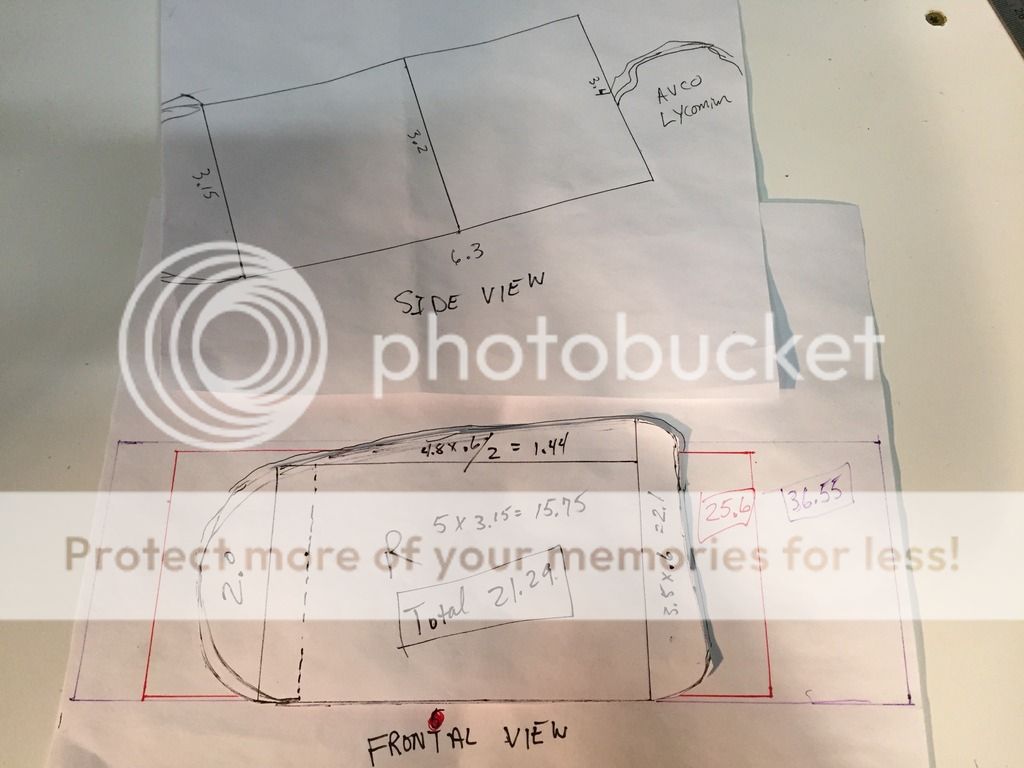

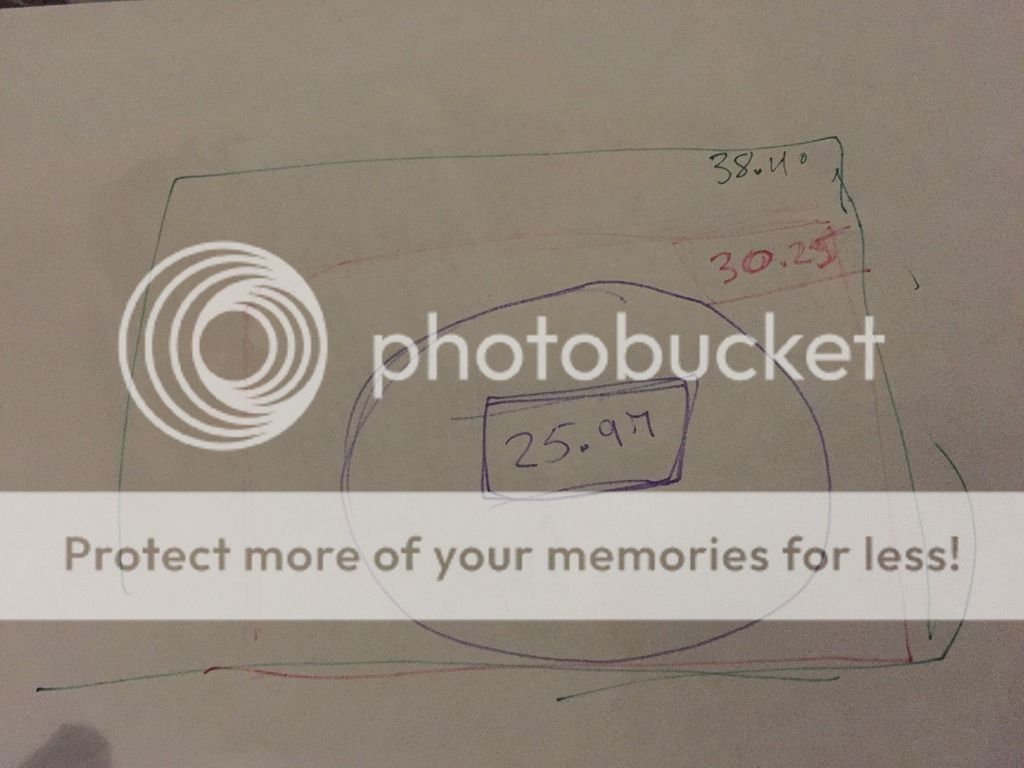

Working out the idea, early 2009: