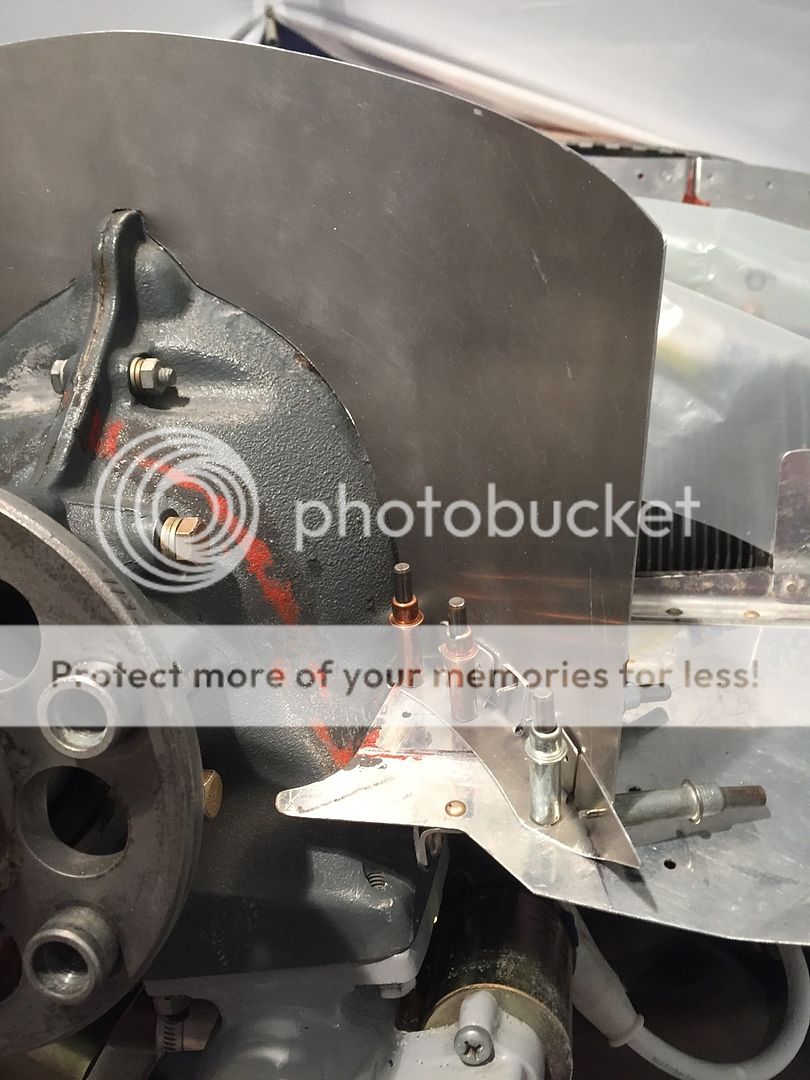

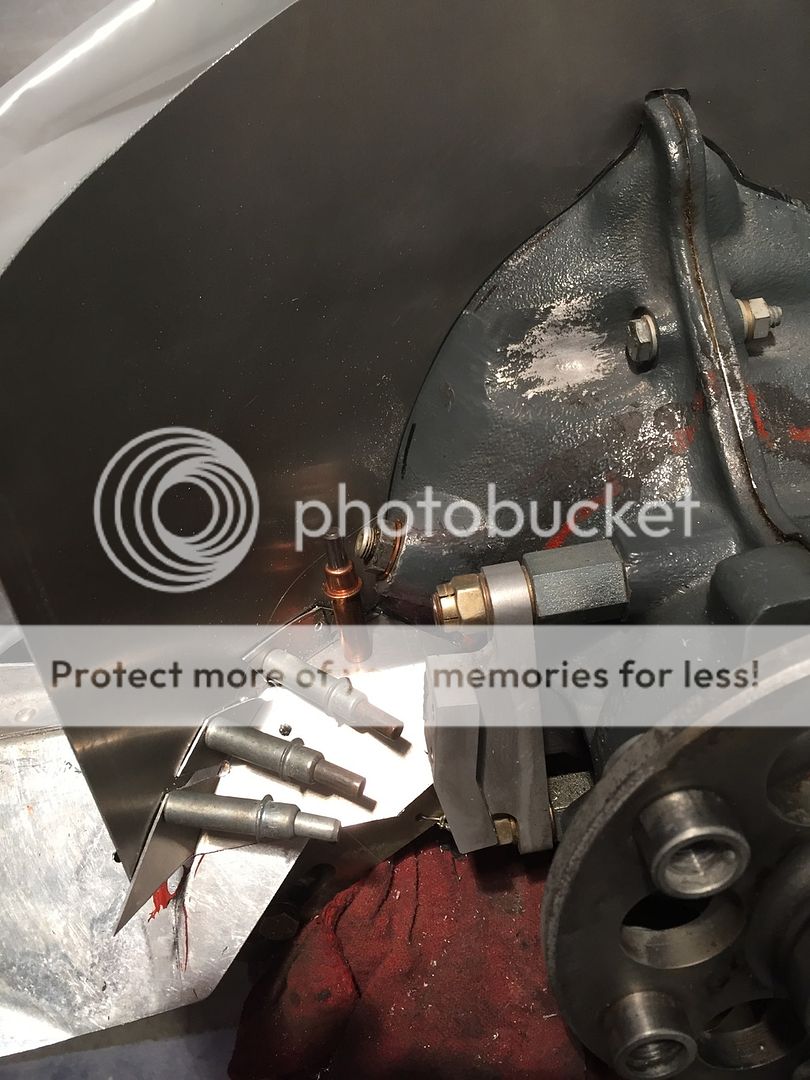

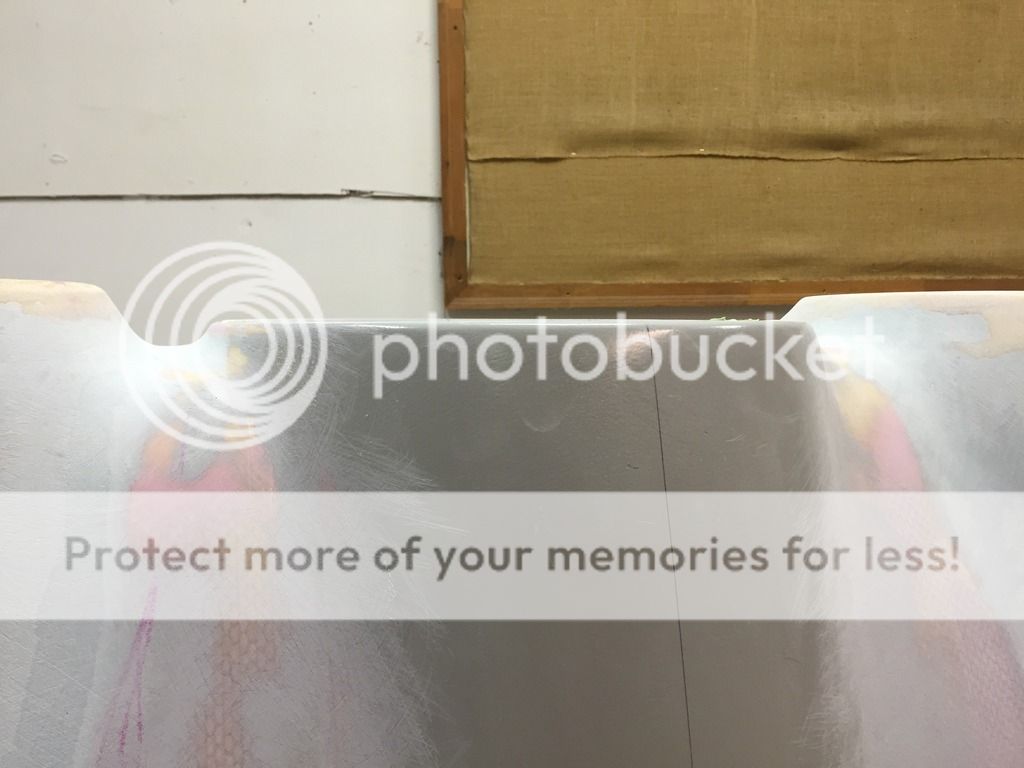

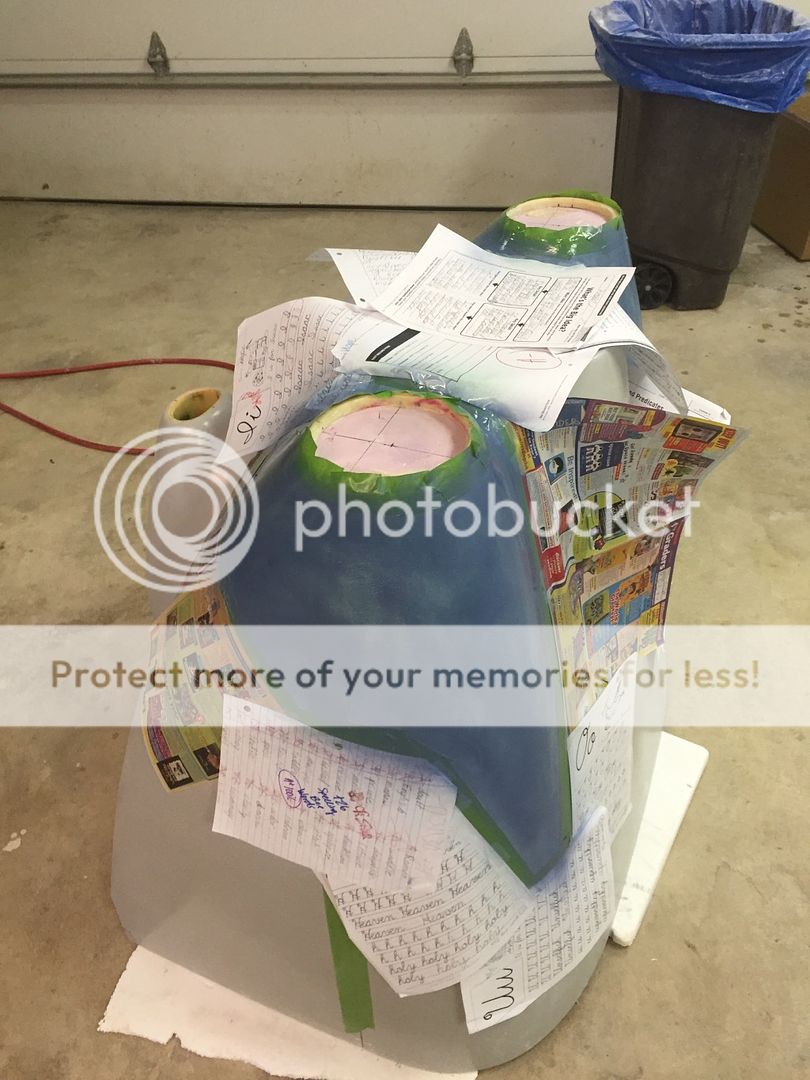

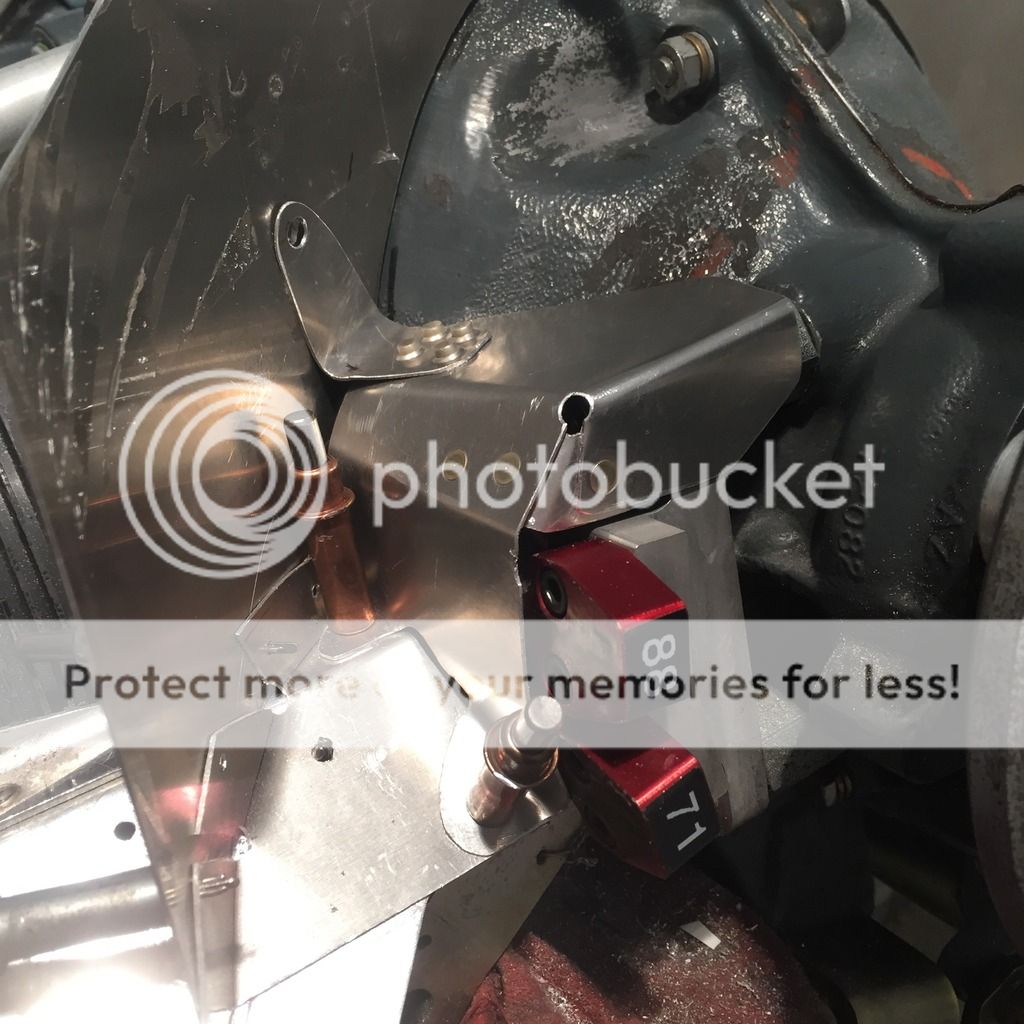

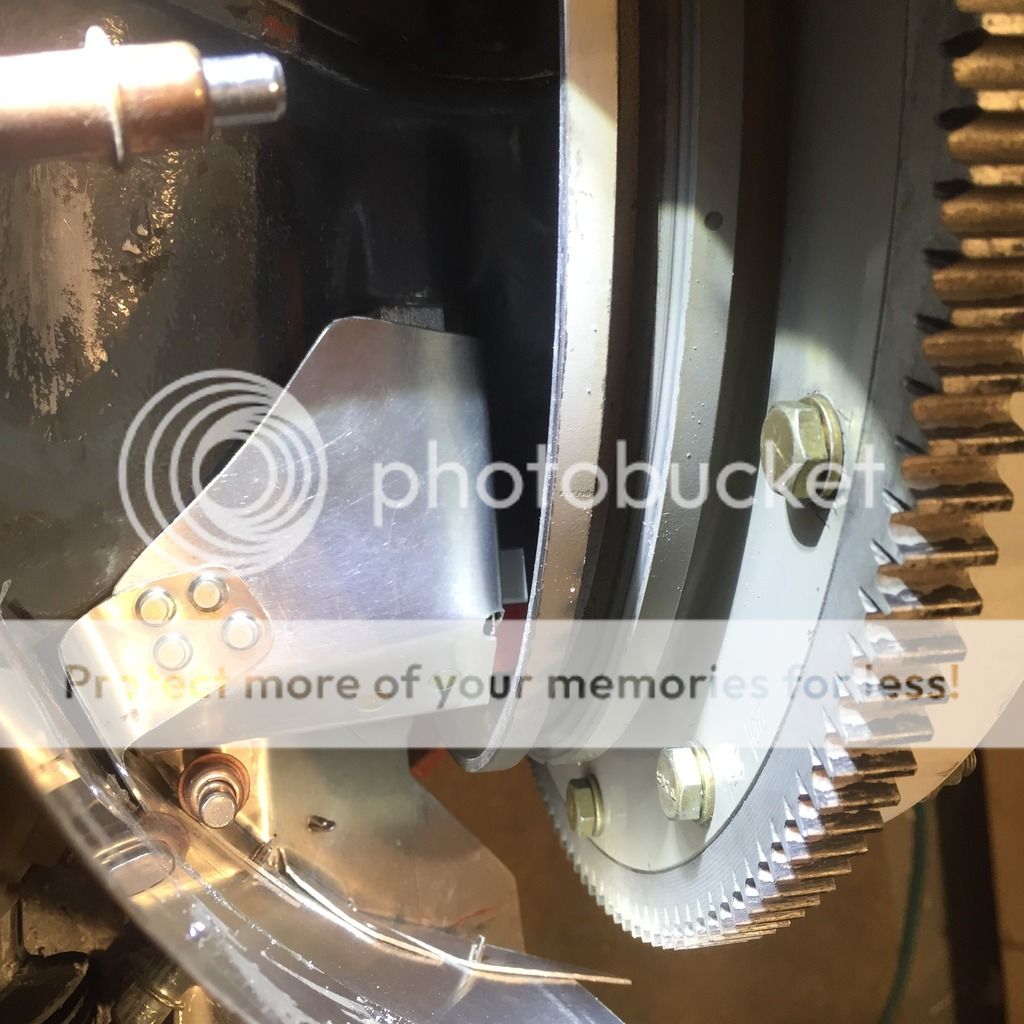

As long as I measured correctly it should work, I was surprised how far forward I was able to bring the inlets. I temporarily mounted the prop to check clearances, the inboard blade trailing edge is about 1 1/8 from the flat face of the cowling behind the spinner.

More clearance outboard due to the blade shape of the Catto.

More clearance outboard due to the blade shape of the Catto.