Done!

Well, last week-end we finally finished the taper pin for the nose wheel landing gear on my RV-9A, and thought I'd share my results.

Please note: I'm not a machinist, or A/P or anyone who knows anything about this stuff. Only sharing what I did.

I followed the Jim Ellis instructions pretty close but with some important additions (at least for me)

Jim's instructions are here:

http://www.matronics.com/wiki/index.php/Nose_Gear_Strut

First. I made sure the motor mount was secured to the work table. I used adel clamps and screwed it to the work bench:

NOTE Towels and plastic. I used LOTS of oil!

Next I drilled out the hole first with a 3/16, then the S that Jim recommends. Use a powerful 1/2 inch drill motor and use LOTS of oil. Go slow and keep the bit clean and well oiled. BruceH said he had trouble drilling. I had none.

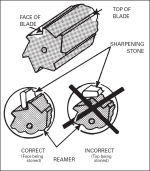

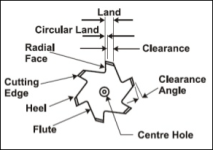

Next I started with the taper. LOTS of oil, only by hand, and take your time. Even though I had a brand new ACS tapered reamer, there seemed to be little cutting, and no good chips that I expected to see. I kept the taper clean and well oiled and still I made almost no progress. After 2 hours, we gave up for the day.

The point here is that the taper never made chips. The reamer looked sharp and was brand new, but after reading all the noise on this site, I figure this is just how it works.

Cruising on eBay, I found a shop that sold reamers for a lot less than I paid, and decided a backup reamer was in order. I talked to Jon at North Bay Cutting Tools and was able to get another taper for about $29 plus shipping. BTW: I screwed up my order and Jon helped me out with great customer service. I bought what I thought was the #3 taper, and it was smaller than my little pinkie!

Anyway, I got the new reamer, and was starting again with the old one. Little progress and no chips. So, what the heck, I'll try the new one.

HOLY COW!!!! What a difference!

It got right to work. So did I.

Follow the same rules: Go slow. LOTS of oil and keep the reamer cleaned out. I turned only a few turns and removed the taper and cleaned out the shavings. Wash, rinse, repeat.

Less than 30 minute later, BINGO. Beautiful.

Here are the added tricks I found:

Anchor your work

Drill twice (3/16 then S) and use a slow turning powerful drill.

Get a good taper reamer. Talk to Jon at [FONT="]

[email protected]

Use LOTS of oil

Ream by hand

Keep the tool clean and free of shavings

Use lots of oil

AND: Check the fit often! This was cutting a lot faster than I thought.

Dkb

[/FONT]