biscuit112

Member

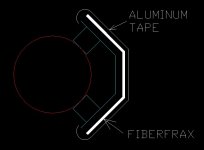

I have been working on my IO-320's idle and cooling for almost a year now. I am a mechanic and pilot but 99% of my PIC time is in gliders... The engine is in a Sam James plenum and cowl. Dear internet come and collect my soul with the judgements of the divine aviation elders (know it alls). Can someone tell me if this idle is to be expected from a bendix FI in a james cowl and plenum. I moved my boost pump from the firewall to the cabin(previous owner's goof). The lines from the servo to the flow divider are as short as I can get them to be on a backdraft intake. The fuel lines out of the flow divider are wrapped elevated as high as possible. .022 restrictors in the injectors. I have a lightweight wooden prop. My idle starts out perfect until 170-200 degrees oil temp comes around. The CHTs and EGTs are uniform and never too hot for all cylinders. The boost pump doesn't change anything. 1300 to max RPM feels stable and clean. I am actually all out of things to do to it and I feel like its the equivalent of race car parts on race car, it just will not idle without lumping. Here is a video. https://www.youtube.com/watch?v=TgzAeOGVeV0

Last edited: