Davepar

Well Known Member

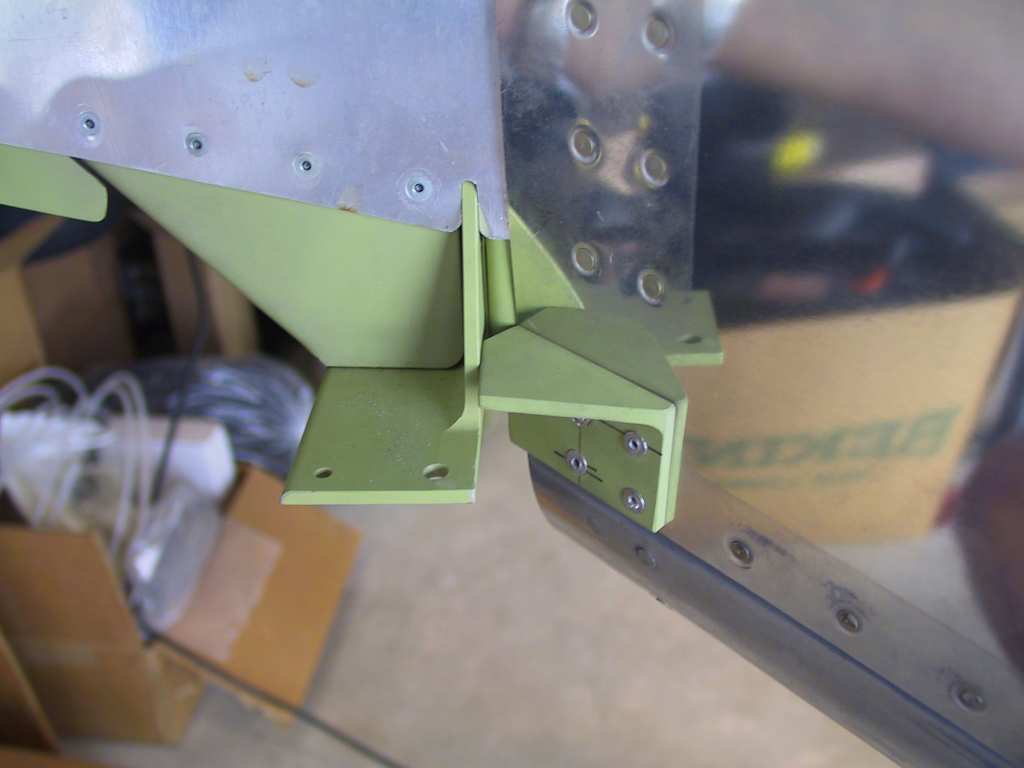

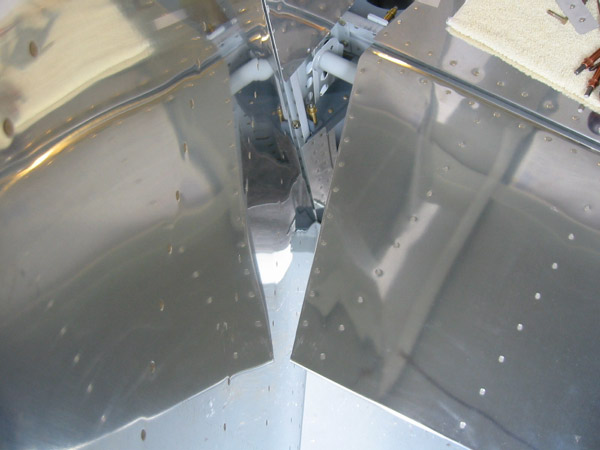

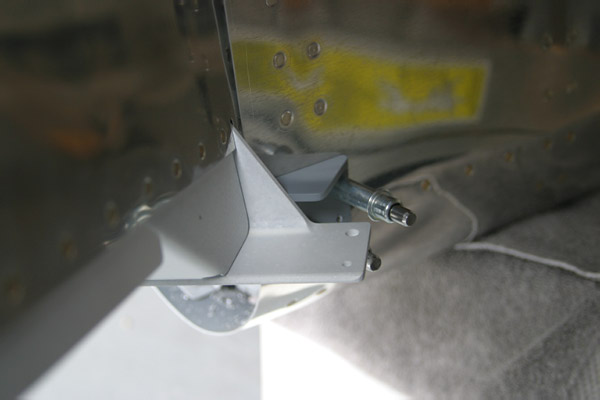

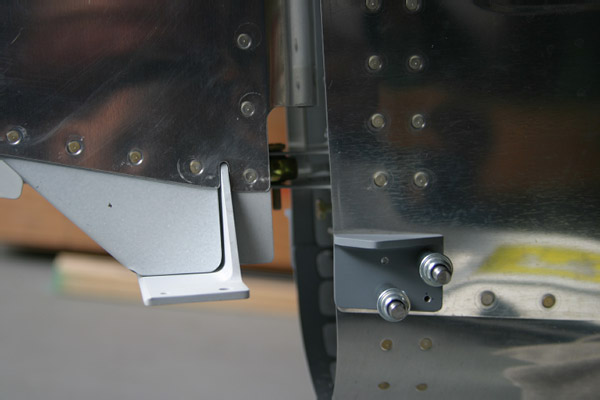

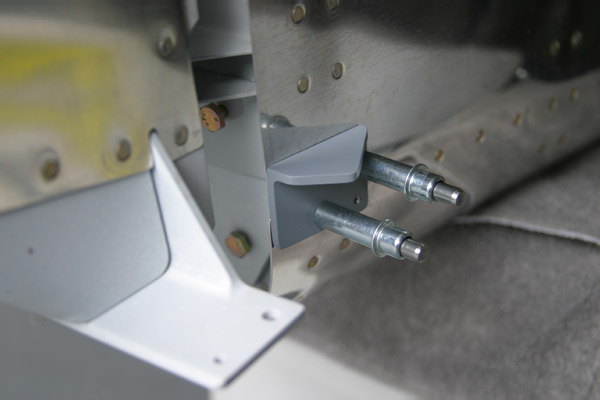

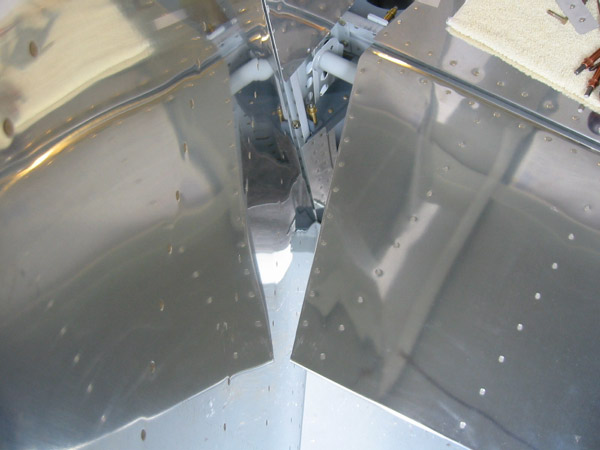

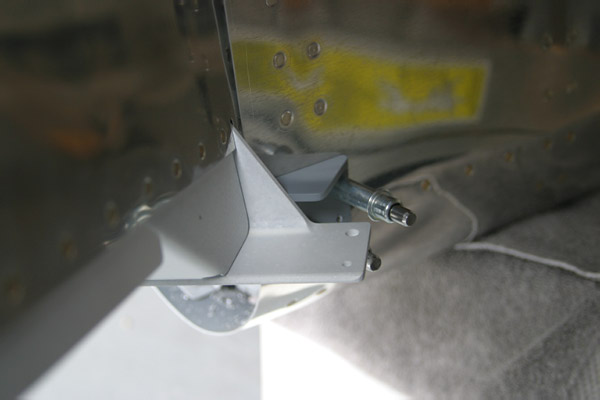

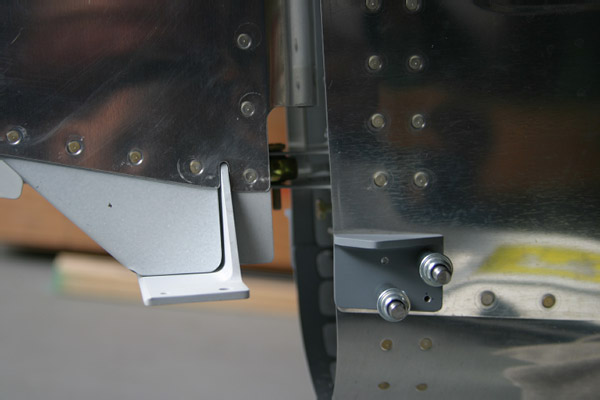

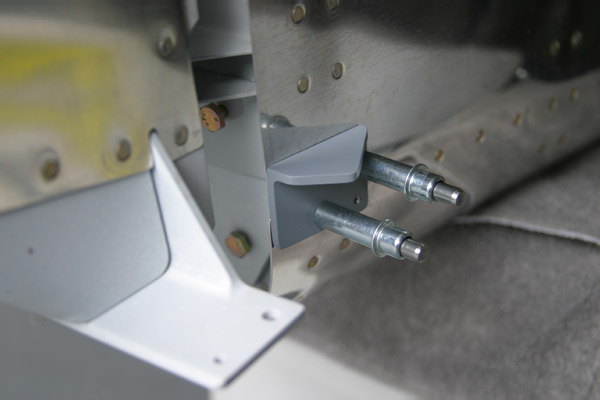

Fitting the empennage to my RV-7A fuselage has been going very well until today. I fitted the new-style rudder, and installed the rudder stops that I carefully fabricated. The rudder bearings were all set to the recommended starting point. Instead of 1-1/8" of clearance between the rudder and elevators, it was more like 1/8". And the rudder swung much further than 35 degrees.

I searched through the old Yahoo Groups RV-7 archives. There was a thread about this a while back. It seems that some builders have no problem and others do. Is there any new info on this problem?

I tried cranking in the bottom bearing. It's now in quite a bit, 29/32", from the recommended starting point, 1-1/16". The gap is now better, but still only 1/2". There's not much more I crank in the bottom bearing. There are only a few more threads exposed.

Here's the current state:

Should I keep cranking in the bearings, or just make new rudder stops?

Thanks,

Dave

I searched through the old Yahoo Groups RV-7 archives. There was a thread about this a while back. It seems that some builders have no problem and others do. Is there any new info on this problem?

I tried cranking in the bottom bearing. It's now in quite a bit, 29/32", from the recommended starting point, 1-1/16". The gap is now better, but still only 1/2". There's not much more I crank in the bottom bearing. There are only a few more threads exposed.

Here's the current state:

Should I keep cranking in the bearings, or just make new rudder stops?

Thanks,

Dave

Last edited: