I am over my head with the wiring on this plane! I bought the AeroLEDS at AV and picked them up direct at the factory in Boise. What a great group of people there. It is always a treat to see Susan! Dean is VERY patient when I had to go back in to ask for help.

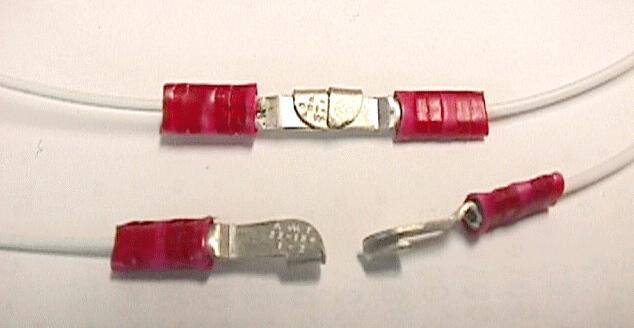

I still couldn't get the connectors figured out so I made a mock-up of the wires from the power supply through the switches and to the lights. To my surprise, it worked on the first try!

I had the idea I could just make cables with d-sub connectors to go from the panel area to each light. What this showed me was that is not correct - at least I couldnt figure out how to do it. Now I can start stringing wire and know that it will work.

I am still unsure on how to join all the wires when I feed them from the panel. I want as few of connections as possible. My plan is to run wires from the lights to under the seats where I will have a splicing or terminal located to take the power wires from the panel.

Does that sound correct?

Did you use a terminal block, d-sum, molex, or splices? If anyone has a photo, that would be great.

[/URL][/IMG]

[/URL][/IMG]

Thanks

I still couldn't get the connectors figured out so I made a mock-up of the wires from the power supply through the switches and to the lights. To my surprise, it worked on the first try!

I had the idea I could just make cables with d-sub connectors to go from the panel area to each light. What this showed me was that is not correct - at least I couldnt figure out how to do it. Now I can start stringing wire and know that it will work.

I am still unsure on how to join all the wires when I feed them from the panel. I want as few of connections as possible. My plan is to run wires from the lights to under the seats where I will have a splicing or terminal located to take the power wires from the panel.

Does that sound correct?

Did you use a terminal block, d-sum, molex, or splices? If anyone has a photo, that would be great.

Thanks