I know that the consensus is to install the wing tips after final rigging. But.....

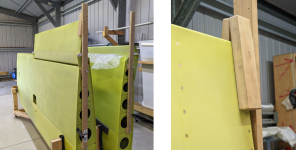

Is it true that all rigging of the ailerons, flaps and wing tips starts with jigging the aileron to the design position lined up per the plans? I have mine in that position with the W-730 jig holding all solidly. It was super easy to do the RV14 tips in the wing stand because the flap set the aileron and thus the tip alignment. It worked out great.

??--> How much error is likely to be introduced if I fit the tips in the wing stands with the aileron in the design neutral position?

Is it true that all rigging of the ailerons, flaps and wing tips starts with jigging the aileron to the design position lined up per the plans? I have mine in that position with the W-730 jig holding all solidly. It was super easy to do the RV14 tips in the wing stand because the flap set the aileron and thus the tip alignment. It worked out great.

??--> How much error is likely to be introduced if I fit the tips in the wing stands with the aileron in the design neutral position?