czechsix

Well Known Member

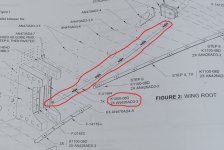

RV-14 plans page 29-18 shows K1000-08D nutplates along the edge of the F-01484 bottom fuselage skin where the lower wing intersection fairing attaches, indicating panhead screws in this location. K1100 nutplates for flush #8 screws are used everywhere else on the wing/fuselage intersection fairings, and I can't see why they couldn't be used along the F-01484 bottom skin as well.

Looking at pics of Van's demo airplanes, it appears their original RV-14A prototype uses flush screws in this location, but the RV-14 demo and the silver RV-14A demo (both of which were built to production parts/plans) use the panhead screws per the plans, so presumably Van's had a reason for this change...anyone know why? Maybe the panheads make the fairing lay down flatter with less 'pucker' in between the screws, or is there something else I'm missing?

Looking at pics of Van's demo airplanes, it appears their original RV-14A prototype uses flush screws in this location, but the RV-14 demo and the silver RV-14A demo (both of which were built to production parts/plans) use the panhead screws per the plans, so presumably Van's had a reason for this change...anyone know why? Maybe the panheads make the fairing lay down flatter with less 'pucker' in between the screws, or is there something else I'm missing?