This is how I did it. I wanted a stiff fairing that would resist bowing or blowing out during flight, but I didn't want the hassle of aluminum (like fiberglass isn't a hassel ????). To make the layup even stiffer, I used carbon fiber. An internet searched provided several sources and some offered discounts on "leftovers" which saved a bunch of money and worked great. As you can see from the pics, the epoxy is black. I added black coloring pigment to the epoxy because I wanted the inside of the layup to match the black sikaflex (I know, my canopy will blow off).

So okay:

1. Cover everything that you don't want glued down with clear packing tape. Also apply strips of packing tape from the canopy to the fuse skin. Make the tape as tight as possible. This will provide the transition from canopy to fuse and will actually be the shell for laying down the glass. I then put a coat of car wax on that. It helps "release" the lay-up once cured. An air gun helps also.

You can kind of see the strips of clear tape in the first pic. Don't worry if it isn't perfectly tight. That's what microballoons are for. Cover everything you don't want glue on with newspaper or something.

2. Put on your respirator. Carbon fiber is nasty stuff. It itches my skin like crazy so imagine what its doing to the lungs. Another caution. DO NOT get carbon fiber on aluminum. It WILL cause it to corrode. I laid up one layer of fiberglass, one layer of carbon fiber, one layer of fiberglass, one layer of carbon fiber, and two layer of fiberglass. This way, the fiberglass will be next to the aluminum and the top two layers of fiberglass are for sanding down. It kind of gives me a bit of a hedge so that I don't sand into the carbon fiber and send carbon dust all over the aluminum. Okay, having said all this, there is no doubt lots of carbon fiber floating around in the air just from the process of unrolling the roll, cutting the stuff, caring it around, brushing on the epoxy, etc. etc. I just tried to be as careful as I could. Hey, it's not a perfect world.

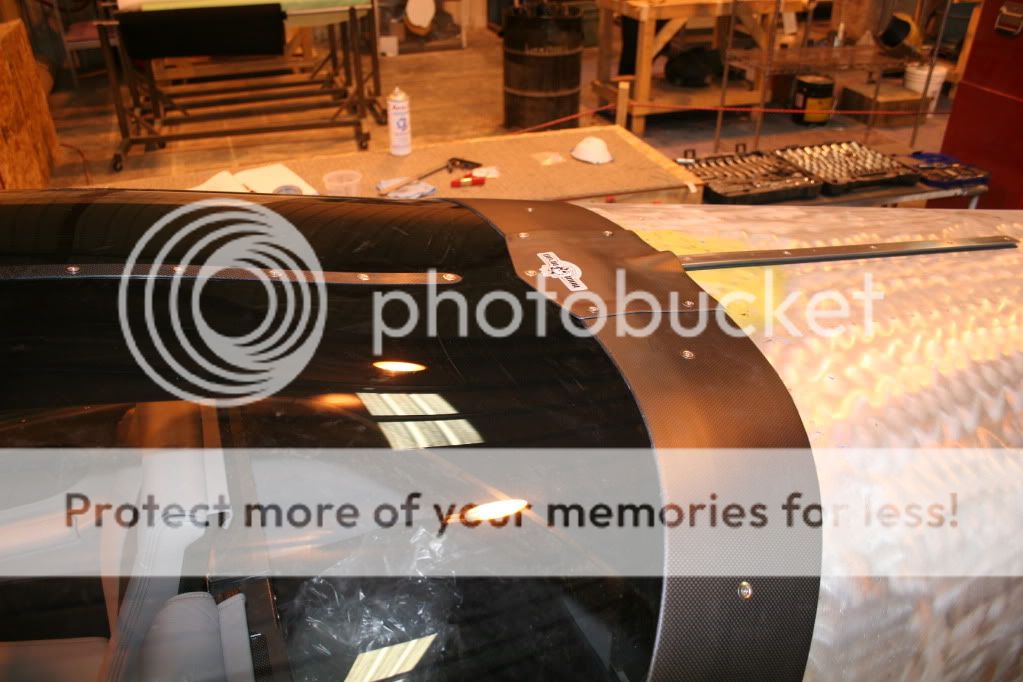

3. I did the entire fairing including both sides and rear in one big layup. I did overlap the glass a couple of inches and tried to space the overlaps in different places to avoid a lump - but sometimes thats kind of hard to do. You can kind of see the overlaps in the corners of the fairing in the next to the last pic.

4. The dog house. I took the little pre-formed aluminum dog house thingy and tack glued it in a couple of places to the fuse and then put a couple of layers of saran wrap over it. Then I just layed the class over that. It turned out okay, but, unless that seal between the nylon slider thingy and the dog house thingy isn't perfect, you will feel the air on the back of your neck. Once done, you can throw the aluminum thingy away. Again, you can see from the pic that the layup in this area isn't perfect but like I said, that's what epoxy and micro-balloons are for.

5. As you can see, I'm not the neatest builder in the world, but it does all clean up, except the concrete. Epoxy will soak into concrete (and your clothes) faster than you can grab the acetone, so like said, if you don't want epoxy on it, cover it.

6. Once you're done with the layup, go get a cold one. Then get another. This took most of the afternoon.

7. Don't get in a hurry to pop off the layup. It's way easier to do the filling and sanding now. I didn't use microballoons but I wish I would have. I can't remember what I did use as a sanding sealer, but as I recall it was one part white goo, one part blue goo, and a few drops of a clear activator. It was expensive as thunder and didn't go that far and was incredibly hard to sand.

I used West Systems epoxy with the fast hardener, 8.8 oz bid fiberglass

http://www.aircraftspruce.com/catalog/cmpages/rutan.php

and about the same weight carbon fiber. This weight cloth is easy to layup and saturate and the bid or bi-directional allows you to contour curves like the doghouse thingy real easy. After the initial layup cures, be sure to sand the whole thing with course sand paper prior to filling.

Finally, I just saw Chris Frisella's work and am wondering why I'm posting all this non-sense.