PaulvS

Well Known Member

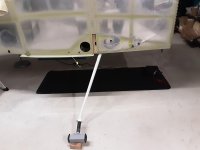

Installing the main wheels on a -6A, the first step is to fit the U-403 flange brackets onto the axles to mount the brake calipers and the wheel pant brackets.

The gear legs have the holes already pre-drilled in the axles for the 5/16" bolt that pins the U-403 in place, and the U-403s that I just recently bought were also pre-drilled.

When the U-403s are mounted onto the axles the position appears incorrect and instead of being oriented vertically they are rotated forward by 27 degrees. The plans indicate that the bolt hole should be horizontal, however it is inclined 27 degrees, causing the flange to be in the incorrect position.

Normally in a situation like this I check to see what I did wrong. However, the gear legs are in the correct sockets L&R. The axles are also aligned, so the gear legs are oriented correctly in the sockets. The only thing I can think of is that the gear legs were drilled incorrectly at the factory. Anyone recall this happening before, mid 90s?

I've contacted Van's support over a week ago but no response yet, I guess they are busy dealing with the laser cut parts problems.

As for the remedy, I'm hoping to be able to re-drill the holes in the flange brackets to match the holes in the axle. I stripped off the powder coating and took the parts to a local TIG welder for him to fill in the existing holes. I'm hoping that there won't be any interference between the bolt and the caliper!

The gear legs have the holes already pre-drilled in the axles for the 5/16" bolt that pins the U-403 in place, and the U-403s that I just recently bought were also pre-drilled.

When the U-403s are mounted onto the axles the position appears incorrect and instead of being oriented vertically they are rotated forward by 27 degrees. The plans indicate that the bolt hole should be horizontal, however it is inclined 27 degrees, causing the flange to be in the incorrect position.

Normally in a situation like this I check to see what I did wrong. However, the gear legs are in the correct sockets L&R. The axles are also aligned, so the gear legs are oriented correctly in the sockets. The only thing I can think of is that the gear legs were drilled incorrectly at the factory. Anyone recall this happening before, mid 90s?

I've contacted Van's support over a week ago but no response yet, I guess they are busy dealing with the laser cut parts problems.

As for the remedy, I'm hoping to be able to re-drill the holes in the flange brackets to match the holes in the axle. I stripped off the powder coating and took the parts to a local TIG welder for him to fill in the existing holes. I'm hoping that there won't be any interference between the bolt and the caliper!