For background, yes, I do know that intersection fairings are available and can be adapted. I am not interested in those, but have been interested in the RV12iS main gear seals since I saw them on the prototype iS airplane at Aurora. The hole in the fuselage for the main gear leg is large and unsightly. Also, there may be benefit of lowered CO getting into the cockpit. My airplane in normal cruise shows 3-4 ppm CO. I do have the firewall well sealed and wing seals installed so the gear openings are the largest openings and are in the exhaust slipstream especially on the starboard side. This level of CO is not alarming at all, I think OSHA limits for CO are something like 35-50 ppm for 8 hours. I know airplanes can go high where the CO matters more, but without researching I don't know if FAA has CO limits anywhere in the regs.

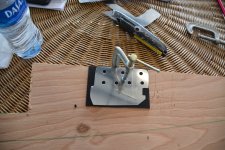

The iS gear seals can be installed on the legacy RV12. The only deviation from the iS installation are four screw locations on each side where it was impossible, for me anyway, to fish in plate nuts. I used Truss Head type A 8X1/2 SS SHT MTL screws from ACsprce for those locations. See picture. I am not real happy using sheet metal screws but they are a better option than rivnuts and won't prove to be a problem. The screw hole is small and the sheet metal screws can be replaced by LP4-3 rivets. There are several locations where CS4-4 flat head rivets are used. I removed the LP4-3 and countersunk those holes slightly with a deburring tool and pulled in the CS4-4.

I have many details of this retro-fit if there is any interest.

The iS gear seals can be installed on the legacy RV12. The only deviation from the iS installation are four screw locations on each side where it was impossible, for me anyway, to fish in plate nuts. I used Truss Head type A 8X1/2 SS SHT MTL screws from ACsprce for those locations. See picture. I am not real happy using sheet metal screws but they are a better option than rivnuts and won't prove to be a problem. The screw hole is small and the sheet metal screws can be replaced by LP4-3 rivets. There are several locations where CS4-4 flat head rivets are used. I removed the LP4-3 and countersunk those holes slightly with a deburring tool and pulled in the CS4-4.

I have many details of this retro-fit if there is any interest.