I've PM TSFlightlines and awaiting a response. I'm also considering the possibility of re-manufacturing the hoses myself for the reasons of down time. Does anyone know of an online tutorial that will show the technique and process of rebuilding hoses. I know I would need to purchase the mandrels. I've done this decades ago, but I just feel I need a refresher if I am to do this myself. Thanks.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuilding oil/fuel hoses

- Thread starter N62XS

- Start date

Freemasm

Well Known Member

I’ve fabbed and re-rehabbed dozens of flex hoses from sense lines to process lines to high press apps like brakes and hydraulics. It is not that hard but I will say that the proper mandrels are a must. They must be threaded to engage the b-nut (? Check my terminology. It’s been a while) the perpendicular through holes or wrench flats are a must. Some can take some considerable torque. Without such, it would not be hard to damage the inside liner. The two most important criteria IMO:

Proper gap on the collar

Proof pressure test

The inner Al parts expand/contract faster than the material which expands faster than the outside collar. Without that gap, the resulting strain from differing thermal expansion rates can easily make the part fail. The gap is more essential than would appear.

If you were closer you could borrow mine. I’ve made my last hose as I’m a TSflightlines fan-boy now. Nothing else will ever be in my aircraft. The related delivery time is relatively short.

I’m a tool jumkie so I only sell my duplicates. I can at least help out my hangar neighbors that aren’t converts yet or locked in by their aircraft TCs.

Edit = sorry. I believe the material you asked about is in the A&P mechanics general handbook. Been a while since I looked.

Proper gap on the collar

Proof pressure test

The inner Al parts expand/contract faster than the material which expands faster than the outside collar. Without that gap, the resulting strain from differing thermal expansion rates can easily make the part fail. The gap is more essential than would appear.

If you were closer you could borrow mine. I’ve made my last hose as I’m a TSflightlines fan-boy now. Nothing else will ever be in my aircraft. The related delivery time is relatively short.

I’m a tool jumkie so I only sell my duplicates. I can at least help out my hangar neighbors that aren’t converts yet or locked in by their aircraft TCs.

Edit = sorry. I believe the material you asked about is in the A&P mechanics general handbook. Been a while since I looked.

Last edited:

Roadjunkie1

Well Known Member

Making hoses....

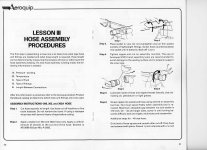

I bought the mandrels years ago when commercially-available hoses were not really an option. Aeroquip put out an assembly bulletin AA124 which I have a copy of but can't find it on line. I put them to use about every 5-7 years or so. Once you get the hang of it, it makes sense and becomes easier to do.

There are multiple UTube tutorials on making them because race cars use them as well. There some aviation-related tutorials as well but I have not looked for a while.

There are some important steps. I would recommend getting more hose than you need and making a few to screw up on before you make the ones going on your airplane. 1) cutting the hose: I used a fine-blade metal cutter on my armsaw that is for cutting metal. You want a CLEAN and STRAIGHT cut, aided by having tape on your cut end. The manual recommends a fine-tooth hack saw. If you are good, that might work. 2) look in the hose and make sure it is CLEAN both from debris from being cut and just junk that shows up in hose. I had Aeroquip hose once brand new from ACS years ago that was defective and the channel was completely blocked. 3)As above, pay attention to the gap between the fitting and the hose. 4) Lubricate the mandrel with something really thick and slick: STP works well. 5) check the hose after assembly to make sure there is no residual junk in the hose. Blow and solvent them out. 6) have them pressure-tested. Your local hydraulic hose company (for industrial hoses) should be able to do that, and sometimes for free just because they will think it was cool you made your own hoses! The time NOT to pressure-test them is on your airplane!

3)As above, pay attention to the gap between the fitting and the hose. 4) Lubricate the mandrel with something really thick and slick: STP works well. 5) check the hose after assembly to make sure there is no residual junk in the hose. Blow and solvent them out. 6) have them pressure-tested. Your local hydraulic hose company (for industrial hoses) should be able to do that, and sometimes for free just because they will think it was cool you made your own hoses! The time NOT to pressure-test them is on your airplane!

YMMV. Disclaimer: Just because my hoses work well does not guarantee yours will. It is up to you to make sure the hoses you make yourself are the best they can be. If you are not comfortable with your hose-making talents, get them from TSFlightlines if you want a quality, pressure-tested hose.

I found the Bulletin and have copied it. Hope this helps....

I’ve fabbed and re-rehabbed dozens of flex hoses from sense lines to process lines to high press apps like brakes and hydraulics. It is not that hard but I will say that the proper mandrels are a must. They must be threaded to engage the b-nut (? Check my terminology. It’s been a while) the perpendicular through holes or wrench flats are a must. Some can take some considerable torque. Without such, it would not be hard to damage the inside liner. The two most important criteria IMOroper gap on the collar

Proof pressure test

The inner Al parts expand/contract faster than the material which expands faster than the outside collar. Without that gap, the resulting strain from differing thermal expansion rates can easily make the part fail. The gap is more essential than would appear.

I’m a tool jumkie so I only sell my duplicates. I can at least help out my hangar neighbors that aren’t converts yet or locked in by their aircraft TCs.

I bought the mandrels years ago when commercially-available hoses were not really an option. Aeroquip put out an assembly bulletin AA124 which I have a copy of but can't find it on line. I put them to use about every 5-7 years or so. Once you get the hang of it, it makes sense and becomes easier to do.

There are multiple UTube tutorials on making them because race cars use them as well. There some aviation-related tutorials as well but I have not looked for a while.

There are some important steps. I would recommend getting more hose than you need and making a few to screw up on before you make the ones going on your airplane. 1) cutting the hose: I used a fine-blade metal cutter on my armsaw that is for cutting metal. You want a CLEAN and STRAIGHT cut, aided by having tape on your cut end. The manual recommends a fine-tooth hack saw. If you are good, that might work. 2) look in the hose and make sure it is CLEAN both from debris from being cut and just junk that shows up in hose. I had Aeroquip hose once brand new from ACS years ago that was defective and the channel was completely blocked.

YMMV. Disclaimer: Just because my hoses work well does not guarantee yours will. It is up to you to make sure the hoses you make yourself are the best they can be. If you are not comfortable with your hose-making talents, get them from TSFlightlines if you want a quality, pressure-tested hose.

I found the Bulletin and have copied it. Hope this helps....

Attachments

Roadjunkie1

Well Known Member

Hoses

I have seem some pretty ratty looking hoses as well. It is a little bit of an art to make good hoses. Ask Tom! If you are not comfortable with making your own hoses, then DON'T. They are a pretty important part of the airplane.

If you are not comfortable with making your own hoses, then DON'T. They are a pretty important part of the airplane.

Right with you on T-S Flightlines. I've seen homemade hoses on some of the RVs I've bought. Terrible. A quick call to Tom and a couple of days later, beUtiful, pre-pressure tested, hoses arrive.

I have seem some pretty ratty looking hoses as well. It is a little bit of an art to make good hoses. Ask Tom!

Christopher Murphy

Well Known Member

EAA had a good video

If you are using 303 hose just buy the mandrel sizes you need. They make it easier and you will get better quality.

Its nice to see someone still interested in the amature part of EAB!

If you can't find that EAA "how too" video let repost and im sure you will get some good tips.

Cm

If you are using 303 hose just buy the mandrel sizes you need. They make it easier and you will get better quality.

Its nice to see someone still interested in the amature part of EAB!

If you can't find that EAA "how too" video let repost and im sure you will get some good tips.

Cm

It is a little bit of an art to make good hoses.

Hmmm I just don't recall it being tricky at all. I made mine up without dedicated mandrels and 1300 hours later no leaks and they are still like new. It's a simple process.

erich weaver

Well Known Member

Hmmm I just don't recall it being tricky at all. I made mine up without dedicated mandrels and 1300 hours later no leaks and they are still like new. It's a simple process.

I agree. Nothing wrong with doing it yourself, just know that you won’t be saving any money over having TS Flightlines do it for you.

Stewbronco

Well Known Member

TS FLIGHTLINES ALL THE WAY

I have made my last hose … not economically viable and the quality and customer service at TS FLIGHTLINES can not be beat

I have made my last hose … not economically viable and the quality and customer service at TS FLIGHTLINES can not be beat

Guys, it depends on WHAT HOSES you have. H8794 or more commonly Aeroquip 303/Stratoflex 111, use mandrels for the straight hose ends. 701/156 hose dont. They either have a large stem taper, or a 'cutter' stem that seals against the rubber liner.

Some may have teflon with reusable hose ends, so just replace the ferulles (olives) with the hose. Vast majority of teflon now have crimped/swaged hose ends. You'd destroy the collars trying to replace the hose ends, them if yo were lucky and had some replacement collars, you'd need a hose crimping press with the proper dies.

So it depends on what you have.

Robby---check your PMs from yesterday!

Tom

Some may have teflon with reusable hose ends, so just replace the ferulles (olives) with the hose. Vast majority of teflon now have crimped/swaged hose ends. You'd destroy the collars trying to replace the hose ends, them if yo were lucky and had some replacement collars, you'd need a hose crimping press with the proper dies.

So it depends on what you have.

Robby---check your PMs from yesterday!

Tom

Robby---email me a pic to [email protected], so I can identify the hoses you have, then we'll how what to do!!

Tom

Tom

Rallylancer122

Well Known Member

When I was a kid every A&P overhauled engines and everyone made their own hoses. Now it seems both need to be done by specialists. Not sure why. For decades everyone flew behind field manufactured hoses.

An angle grinder with a 1/16" cut off wheel does an excellent job cutting the hose.

One of the things I do is shove my borescope down the completed hose to check for scalloping.

An angle grinder with a 1/16" cut off wheel does an excellent job cutting the hose.

One of the things I do is shove my borescope down the completed hose to check for scalloping.

Dennis, part of the reason is the transition from a rubber lined hose to teflon. The replacement intervals for rubber hoses have been documented several times, and even then, sometimes the additives in fuel attack the liners, and create a premature failure. This hose looks great, BUT--

https://youtu.be/uu__Wt0ImLk

well, you get the idea. The benefits of teflon are also well documented, and can be assembled with hand tools with reusable hose ends. Stainless reusables can get expensive, but there are companies out there that have them. Many years ago, we experimented with a 'bulk hose kit" with hose, a variety of common hose ends, firesleeve, bands, etc for the builder to assemble his own hoses. A very well respected member of the VAF community told me that since a pre-made assembly was usually less expensive than the kit form, and the fact that he didnt have to do all the work (more time to do other things), and our assemblies were pressure tested, he felt it was a better value. Some may not agree and thats ok.

If you are rebuilding a 303 or 701 hose and the hose ends are serviceable, then yes its less expensive than a teflon assembly. But IF these hose ends are NOT serviceable, or you need something different, then probably not. Priced a 8891-6D or a 980005-6 hose end lately? It might surprise you. Most builders dont want to fabricate their own assemblies, and thats the service we offer.

Tom

https://youtu.be/uu__Wt0ImLk

well, you get the idea. The benefits of teflon are also well documented, and can be assembled with hand tools with reusable hose ends. Stainless reusables can get expensive, but there are companies out there that have them. Many years ago, we experimented with a 'bulk hose kit" with hose, a variety of common hose ends, firesleeve, bands, etc for the builder to assemble his own hoses. A very well respected member of the VAF community told me that since a pre-made assembly was usually less expensive than the kit form, and the fact that he didnt have to do all the work (more time to do other things), and our assemblies were pressure tested, he felt it was a better value. Some may not agree and thats ok.

If you are rebuilding a 303 or 701 hose and the hose ends are serviceable, then yes its less expensive than a teflon assembly. But IF these hose ends are NOT serviceable, or you need something different, then probably not. Priced a 8891-6D or a 980005-6 hose end lately? It might surprise you. Most builders dont want to fabricate their own assemblies, and thats the service we offer.

Tom