Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Procedure documentation for first engine start

- Thread starter AeroDog

- Start date

I was thinking maybe there was something from Van's or Rotax that's a bit more specific than the PAP without having to pick through the Rotax SI, which seems to give 30 choices for each fluid, etc. For example, regarding coolant the PAP says "Use of standard coolant is recommended." Is there a preferred brand? Mixture ratio?

Jerre

Jerre

Right 'duffers' guide or how I operate!

Oil: Personal choice is Shell Sport Plus 4. In reality any oil on the Rotax list is OK or at a pinch a high grade 4 stroke motorcycle oils that lubricates both engine and gearbox.

Coolant: Personal choice is G48 type antifreeze concentrate mixed 50:50 with distilled water. Avoid tap water!

Bleed the air from the coolant system to give near full just beneath the pressure cap on top of the engine. Don't forget to fill the plastic expansion bottle to the indicated marks. (For the first couple of flights the coolant will drop a bit as the air escapes from the small cavities around the engine and the water gives up its air). Top up as neccessary.

Purge the oil system as the Rotax SI. I cannot stress how important this is!!!!

ANY time you open up the oil system (not just topping up the tank) for example disturbing any oil line pipe connections, changing the oil filter or inspecting the magnetic plug etc. I would suggest you go through this procedure.

Add about 4 gallons of fuel to the tank. I would suggest 100LL Avgas as it might be in there a while before you go flying.

Chock the aircraft, deep breath then start as the POH. You should see oil pressure after 10 seconds, if not shut down immediatly and purge again! Don't forget to test the lifters again.

Let the engine idle at 1800-2000 RPM for 10-15 minutes whilst you keep an eye on all the engine guages and listen to the engine.

Couple of top tips:

ULS: Start the engine on the choke with the throttle fully closed,( There is a reason for this but it'll take a long time to type) as the engine springs to life and the oil pressure rises reduce the choke slowly and increase the throttle to give you the 1800-2000 idle.

iS: Set the throttle to 33%, This is shown on both the Garmin and Dynon displays, it doesn't mean moving the throttle 1/3 of the way forward! Avoid the POH figure of 50% as this is a lot of power on a cold new engine! This should give you about 2000 RPM once started. Watch the oil pressure, again 10 seconds for it to rise.

Both engines:

When you are going to shut down let the engine idle for a while then as you close the throttle turn the key off. This will stop the clunking as the engine shuts down. If you want to know what clunking is, close the throttle wait 2 seconds then turn the engine off.

Have a bit of faith, Rotax run every engine for 60 mins in the factory prior to shipping so in real terms they are almost ready to go.

I've attached a couple of things that may help.

Good luck,

John.

PS If you want any other info just post.

https://www.youtube.com/watch?v=UwARvpIP9-k

Oil: Personal choice is Shell Sport Plus 4. In reality any oil on the Rotax list is OK or at a pinch a high grade 4 stroke motorcycle oils that lubricates both engine and gearbox.

Coolant: Personal choice is G48 type antifreeze concentrate mixed 50:50 with distilled water. Avoid tap water!

Bleed the air from the coolant system to give near full just beneath the pressure cap on top of the engine. Don't forget to fill the plastic expansion bottle to the indicated marks. (For the first couple of flights the coolant will drop a bit as the air escapes from the small cavities around the engine and the water gives up its air). Top up as neccessary.

Purge the oil system as the Rotax SI. I cannot stress how important this is!!!!

ANY time you open up the oil system (not just topping up the tank) for example disturbing any oil line pipe connections, changing the oil filter or inspecting the magnetic plug etc. I would suggest you go through this procedure.

Add about 4 gallons of fuel to the tank. I would suggest 100LL Avgas as it might be in there a while before you go flying.

Chock the aircraft, deep breath then start as the POH. You should see oil pressure after 10 seconds, if not shut down immediatly and purge again! Don't forget to test the lifters again.

Let the engine idle at 1800-2000 RPM for 10-15 minutes whilst you keep an eye on all the engine guages and listen to the engine.

Couple of top tips:

ULS: Start the engine on the choke with the throttle fully closed,( There is a reason for this but it'll take a long time to type) as the engine springs to life and the oil pressure rises reduce the choke slowly and increase the throttle to give you the 1800-2000 idle.

iS: Set the throttle to 33%, This is shown on both the Garmin and Dynon displays, it doesn't mean moving the throttle 1/3 of the way forward! Avoid the POH figure of 50% as this is a lot of power on a cold new engine! This should give you about 2000 RPM once started. Watch the oil pressure, again 10 seconds for it to rise.

Both engines:

When you are going to shut down let the engine idle for a while then as you close the throttle turn the key off. This will stop the clunking as the engine shuts down. If you want to know what clunking is, close the throttle wait 2 seconds then turn the engine off.

Have a bit of faith, Rotax run every engine for 60 mins in the factory prior to shipping so in real terms they are almost ready to go.

I've attached a couple of things that may help.

Good luck,

John.

PS If you want any other info just post.

https://www.youtube.com/watch?v=UwARvpIP9-k

Attachments

Last edited:

Piper J3

Well Known Member

If ULS.... I would definitely run a fast idle on initial start. If carbs are not synched there will be uneven power pulses from L-R sides of the engine and that is bad for gearbox (chatter from gear mesh and drive dogs on overload clutch). Higher idle lets gearbox tolerate dynamic loads. Personally I'd run near 2500 RPM or even a smidge higher. I have over 850 TT on my RV-12 ULS. I use only Mobil 1 Racing 4T Full Synthetic Oil and start the engine and warm up at 2800 RPM...

John: Thanks for the link to the procedure for purging the oil system. This is a vital step that, in my opinion, is not sufficiently stressed (or even referenced) in the PAP. I spoke with one RV-12 builder who confused purging the system with burping the system.

Jim: After reading everything I could find on the topic, I think your advice on the idle speed is good.

Jerre

Jim: After reading everything I could find on the topic, I think your advice on the idle speed is good.

Jerre

Jerre--John: Thanks for the link to the procedure for purging the oil system. This is a vital step that, in my opinion, is not sufficiently stressed (or even referenced) in the PAP. I spoke with one RV-12 builder who confused purging the system with burping the system.

Jim: After reading everything I could find on the topic, I think your advice on the idle speed is good.

Jerre

What is "purging", and how is it different from "burping"? The Rotax Operator's Manual doesn't mention this, nor does the Service Instruction on fluids. I haven't started the engine yet.

--CT Cole

Burping is the daily procedure you do prior to checking the oil level to return all the oil to the tank. Purging is a maintenance procedure you do after opening the oil system (remove hoses etc) to remove all the air from the oil system prior to starting.

For burping, most folks check the oil level first, if it is above the minimum mark - go fly. if not rotate the prop to pump oil to the tank until you here a "gurgle", re-check the oil level & add if required.

Purging involves removing spark plugs and oil return lines, spinning the engine by hand to spin the oil pump and force oil in and air out of the system, then removing the valve covers to verify that the hydraulic lifters are "hard" & contain no air. See the Rotax documentation for the full details.

For burping, most folks check the oil level first, if it is above the minimum mark - go fly. if not rotate the prop to pump oil to the tank until you here a "gurgle", re-check the oil level & add if required.

Purging involves removing spark plugs and oil return lines, spinning the engine by hand to spin the oil pump and force oil in and air out of the system, then removing the valve covers to verify that the hydraulic lifters are "hard" & contain no air. See the Rotax documentation for the full details.

This video might be helpful. And you can download the latest version of SI-912 i-004.

www.rotax-owner.com

www.rotax-owner.com

ROTALK - SI-912 i-004, SI-912-018, SI-914-020, SI-915 i-003 Purging of lubrication system

Video explaining fuel pump assembly and instructions for individual fuel pump replacement for fuel injected ROTAX Aircraft Engines of the 912 i and 915 i Series.

Also, purging requires pressurizing the oil tank so force oil from the tank to the oil pump (if there is air in the oil pump, it won't pull oil from the tank). Pressure levels are relatively low and can be found in the heavy maintenance manual (best to review the full procedure before attempting).Purging involves removing spark plugs and oil return lines, spinning the engine by hand to spin the oil pump and force oil in and air out of the system, then removing the valve covers to verify that the hydraulic lifters are "hard" & contain no air. See the Rotax documentation for the full details.

bbaggerman

Active Member

Typical Rotax, information is a bit of a treasure hunt. The Heavy Maintenance Manual only refers you to the Line Maintenance Manual. The Line Maintenance Manual refers you to the Installation Manual and Service Instruction SI-912-018. The Installation Manual procedure calls for using compressed air but the Service Instruction says compressed air is optional. BTW the Installation Manual also refers you to SI-912-018. Compressed air speeds things along. I've done it with no compressed air IAW SI-912-018 and had satisfactory results. Just a lot of prop turning.Also, purging requires pressurizing the oil tank so force oil from the tank to the oil pump (if there is air in the oil pump, it won't pull oil from the tank). Pressure levels are relatively low and can be found in the heavy maintenance manual (best to review the full procedure before attempting).

Last edited:

The Rotax Installation Manual for Engine Installation for 912 ULS (2007) has detailed instructions under "Purging of Lubrication System". This publication is for ULS, but I think it's the same for 912 iS. We got a copy of this manual with the engine if I recall correctly.

bbaggerman

Active Member

I am not sure running at 2500 RPM does you much good. It was my understanding from the Rotax training I did at Lockwood that running above idle (above about 1800) but below cruise power causes the prop gears to slam against the gearbox dogs. On my engine you can hear the dogs chattering if you know what to listen for above about 2000 RPM. So even if the carbs are perfectly sync'ed 2500 RPM will result in gearbox dog chatter. I don't think running for a short while at 2500 RPM or so is a big deal but don't get in the habit of warming the engine at this speed. It's tempting to run at fast idle to speed up the warmup but don't do it!If ULS.... I would definitely run a fast idle on initial start. If carbs are not synched there will be uneven power pulses from L-R sides of the engine and that is bad for gearbox (chatter from gear mesh and drive dogs on overload clutch). Higher idle lets gearbox tolerate dynamic loads. Personally I'd run near 2500 RPM or even a smidge higher. I have over 850 TT on my RV-12 ULS. I use only Mobil 1 Racing 4T Full Synthetic Oil and start the engine and warm up at 2800 RPM...

For those who are not familiar with Rotax gearbox dogs, the Rotax is an interesting engine with some really interesting engineering features. One feature is that the prop isn't rigidly fixed to the crankshaft. Instead there is about 30 degrees of play possible through a friction coupling. Play is hard limited by some dogs in the gearbox. This play helps smooth out engine power pulses at cruise power. At cruise power the prop shaft doesn't hit the gearbox dog stops but it will hit the dog stops at intermediate power. Hitting the gearbox dog stops is not the end of the world but isn't necessarily a good thing so usually we try to pick an engine speed that doesn't cause this to happen. Idle at or below about 1800 is also a safe RPM range. BTW, this stuff isn't really clearly addressed in the operating manual for the Rotax or the RV-12.

bbaggerman

Active Member

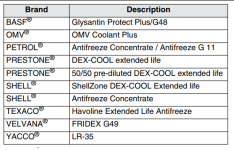

SI-912-016 has this chart for coolant...I was thinking maybe there was something from Van's or Rotax that's a bit more specific than the PAP without having to pick through the Rotax SI, which seems to give 30 choices for each fluid, etc. For example, regarding coolant the PAP says "Use of standard coolant is recommended." Is there a preferred brand? Mixture ratio?

Jerre

50 / 50 mix is recommended. I use the Prestone DEX-COOL 50/50. It is the orange stuff and is easy to find at my local auto parts store. I don't know where to get YACCO!

As for oil, it's pretty much just AeroShell Oil Sport Plus 4. I understand there are high quality motorcycle oils that meet the standard but there doesn't seem to be a compelling reason to go that route. Any oil in this engine needs to be able to withstand the wear it will get in gearbox.

For engine fluids, those two are the biggies.