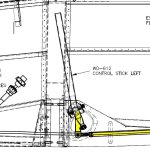

Well known in some circles, but probably worth illustration...

Subject is the stick assembly for the 6, 7, and 9, specifically where it connects to the forward pushrod. See below

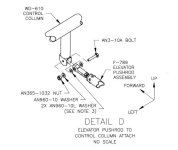

The up elevator limit stop is at the rear of the fuselage; the WD-605 elevator horns should contact F-712D. There should be no binding or springiness as the stick nears full aft, just free motion until the horns hit the 712 with a nice firm clunk.

No clunk, or a springy feeling at full aft? Look back, visually center the elevators, then look at the stick. Is it vertical, or leaning forward?

It should be leaning forward. If not, the built in angles result in the rod end shank binding against the top of the weldment fork; see below. That puts a bending load on the pushrod assembly, notably the AN490 threaded rod end.

Here's a trick which may help the rigging process. Cut a strip of paper about 8 inches long and 1/4" wide. Slip an end into the space above the rod end and move the stick full aft until the elevator horns hit the stop. Now try to pull the paper out of the joint. If it's not free, the joint is binding as below.

.

Subject is the stick assembly for the 6, 7, and 9, specifically where it connects to the forward pushrod. See below

The up elevator limit stop is at the rear of the fuselage; the WD-605 elevator horns should contact F-712D. There should be no binding or springiness as the stick nears full aft, just free motion until the horns hit the 712 with a nice firm clunk.

No clunk, or a springy feeling at full aft? Look back, visually center the elevators, then look at the stick. Is it vertical, or leaning forward?

It should be leaning forward. If not, the built in angles result in the rod end shank binding against the top of the weldment fork; see below. That puts a bending load on the pushrod assembly, notably the AN490 threaded rod end.

Here's a trick which may help the rigging process. Cut a strip of paper about 8 inches long and 1/4" wide. Slip an end into the space above the rod end and move the stick full aft until the elevator horns hit the stop. Now try to pull the paper out of the joint. If it's not free, the joint is binding as below.

.