hk1232

Member

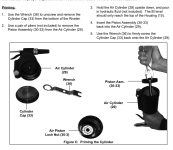

Looking for advise with how to oil the cheap Pneumatic rivet pullers like this one from Harbor Freight:

https://www.harborfreight.com/3-16-inch-air-hydraulic-riveter-93458.html

I've attached the page of the manual that describes this. Step 3 says to fill to the top of the housing which they don't have labeled.

I filled a small amount of the bottom of the cylinder with air tool oil and two things happened --

Spent a lot of time disassembling, cleaning, etc. and the cylinder plunger still automatically repositions halfway through the cylinder after use.

What is the "housing"? How much are you adding? I assume this oil mist means I'm doing it wrong!

https://www.harborfreight.com/3-16-inch-air-hydraulic-riveter-93458.html

I've attached the page of the manual that describes this. Step 3 says to fill to the top of the housing which they don't have labeled.

I filled a small amount of the bottom of the cylinder with air tool oil and two things happened --

- Spitting an oil mist with the exhaust air on each use

- After a few months of sitting I've picked this back up and now the cylinder plunger now gets stuck and only moves half a stroke.

Spent a lot of time disassembling, cleaning, etc. and the cylinder plunger still automatically repositions halfway through the cylinder after use.

What is the "housing"? How much are you adding? I assume this oil mist means I'm doing it wrong!