I picked up a mostly unfinished complete airframe kit and the previous owner only did the first few steps.

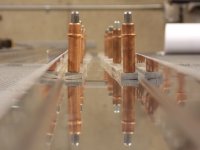

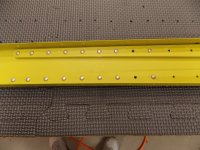

I’m now getting into it and finding that 609pp does not touch the radius of 603pp. There’s about an 1/8” gap from the edge of 609 to the flange of 603. All of the build vids I’ve seen so far have had to do what the plans say which is to radius so it fits in the flange.

The machining on 609 looks factory so I don’t think the previous builder took that much material off.

Is this an issue? Or build on?

I’m now getting into it and finding that 609pp does not touch the radius of 603pp. There’s about an 1/8” gap from the edge of 609 to the flange of 603. All of the build vids I’ve seen so far have had to do what the plans say which is to radius so it fits in the flange.

The machining on 609 looks factory so I don’t think the previous builder took that much material off.

Is this an issue? Or build on?