I'm just getting started on section 11, Empennage Attach, adjusting elevator rod end bearings while fretting about drilling the elevator horns. On the left elevator, adjusting both rod end bearings to the recommended 13/16" height resulted in an even 1/8" gap front-to-back between the counterbalance arm and HS, and 1 5/8" spacing between the torque tube and rear spar (elevator in "trail" position).

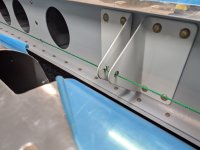

On the right elevator, the same rod end bearing settings resulted in a much larger (3/16"?) arm/HS gap forward, and 1/8" aft. I adjusted the inboard bearing out:

and the outboard bearing in:

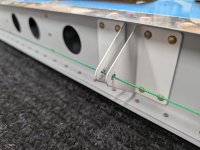

and the outboard bearing in:  . These settings resulted in much closer to the recommended 1/8" arm/HS gap (5/32" forward, 1/8" aft). However, the torque tube spacing was pushed back to about 1 6/8".

. These settings resulted in much closer to the recommended 1/8" arm/HS gap (5/32" forward, 1/8" aft). However, the torque tube spacing was pushed back to about 1 6/8".

So, the counterbalance arm spacing was evened out at the expense of changing the angle of the elevator trailing edge with respect to the HS leading edge. Is this the effect that I should be shooting for?

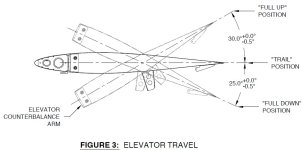

Also, at this point, the plans no longer have you verify the range of motion of the elevators, deferring to page 36-15, rev 1, where it refers to the since removed 11-02, figure 3 (image attached, from rev 0 of page 11-02). This implies that I should wait before I spend much time tweaking the elevator leading edges (I have some rubbing on the hinge brackets around 27° "up" deflection). Is waiting until I find out what's *really* needed the best plan?

On the right elevator, the same rod end bearing settings resulted in a much larger (3/16"?) arm/HS gap forward, and 1/8" aft. I adjusted the inboard bearing out:

and the outboard bearing in:

and the outboard bearing in:  . These settings resulted in much closer to the recommended 1/8" arm/HS gap (5/32" forward, 1/8" aft). However, the torque tube spacing was pushed back to about 1 6/8".

. These settings resulted in much closer to the recommended 1/8" arm/HS gap (5/32" forward, 1/8" aft). However, the torque tube spacing was pushed back to about 1 6/8".So, the counterbalance arm spacing was evened out at the expense of changing the angle of the elevator trailing edge with respect to the HS leading edge. Is this the effect that I should be shooting for?

Also, at this point, the plans no longer have you verify the range of motion of the elevators, deferring to page 36-15, rev 1, where it refers to the since removed 11-02, figure 3 (image attached, from rev 0 of page 11-02). This implies that I should wait before I spend much time tweaking the elevator leading edges (I have some rubbing on the hinge brackets around 27° "up" deflection). Is waiting until I find out what's *really* needed the best plan?